-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 06, 2025 16:23

Back to list

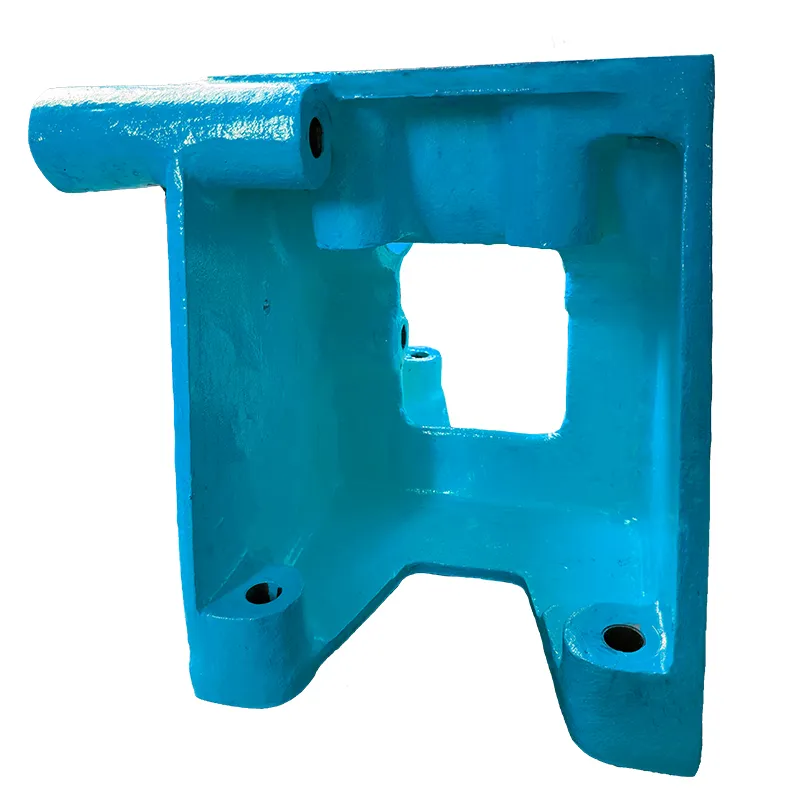

Pump Wear Parts SPR10206 Rubber

A slurry pump is an essential component in industries where transporting solids in a liquid medium is required. To grasp its utility, consider the complexity and demands of projects in mining, dredging, and construction sectors, where the consistency and viscosity of material being pumped present unique challenges. The right pump ensures efficient and cost-effective movement of such materials.

Building trustworthiness in the use of slurry pumps involves adhering to strict maintenance schedules. Regular inspection, such as checking for wear on critical components like the impeller, casing, and shaft sleeves, is fundamental. Also, ensuring proper sealing systems is crucial to prevent leaks, which could lead to environmental hazards if the slurry is hazardous. A trusted operation system records wear patterns and predicts maintenance cycles, significantly reducing downtimes and extending the equipment’s lifecycle. Real-world experience has shown that enhancing the operational life of slurry pumps necessitates sound practices, such as maintaining optimal flow velocity to prevent sedimentation and clogging. Experience from industries worldwide suggests adjustments in operating conditions, and regular performance reviews can yield significant improvements in efficiency and lifespan. Experts in the field recognize the growing emphasis on smart technologies within slurry pump management. Integrating IoT-based monitoring sensors enables real-time data collection and performance analysis, providing operators instant feedback and historical data trends. This modernization not only facilitates predictive maintenance but also enhances the pump’s efficiency and reliability, ensuring it operates within optimal parameters at all times. The global demand for natural resources continues to rise, and the role of slurry pumps becomes even more critical in meeting these demands efficiently. By selecting a pump tailor-made to specific operational needs and maintaining it properly through expert advice and technological advancements, businesses can rely on these robust devices to support sustained productivity and profitability in their operations.

Building trustworthiness in the use of slurry pumps involves adhering to strict maintenance schedules. Regular inspection, such as checking for wear on critical components like the impeller, casing, and shaft sleeves, is fundamental. Also, ensuring proper sealing systems is crucial to prevent leaks, which could lead to environmental hazards if the slurry is hazardous. A trusted operation system records wear patterns and predicts maintenance cycles, significantly reducing downtimes and extending the equipment’s lifecycle. Real-world experience has shown that enhancing the operational life of slurry pumps necessitates sound practices, such as maintaining optimal flow velocity to prevent sedimentation and clogging. Experience from industries worldwide suggests adjustments in operating conditions, and regular performance reviews can yield significant improvements in efficiency and lifespan. Experts in the field recognize the growing emphasis on smart technologies within slurry pump management. Integrating IoT-based monitoring sensors enables real-time data collection and performance analysis, providing operators instant feedback and historical data trends. This modernization not only facilitates predictive maintenance but also enhances the pump’s efficiency and reliability, ensuring it operates within optimal parameters at all times. The global demand for natural resources continues to rise, and the role of slurry pumps becomes even more critical in meeting these demands efficiently. By selecting a pump tailor-made to specific operational needs and maintaining it properly through expert advice and technological advancements, businesses can rely on these robust devices to support sustained productivity and profitability in their operations.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024