-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 06, 2025 16:58

Back to list

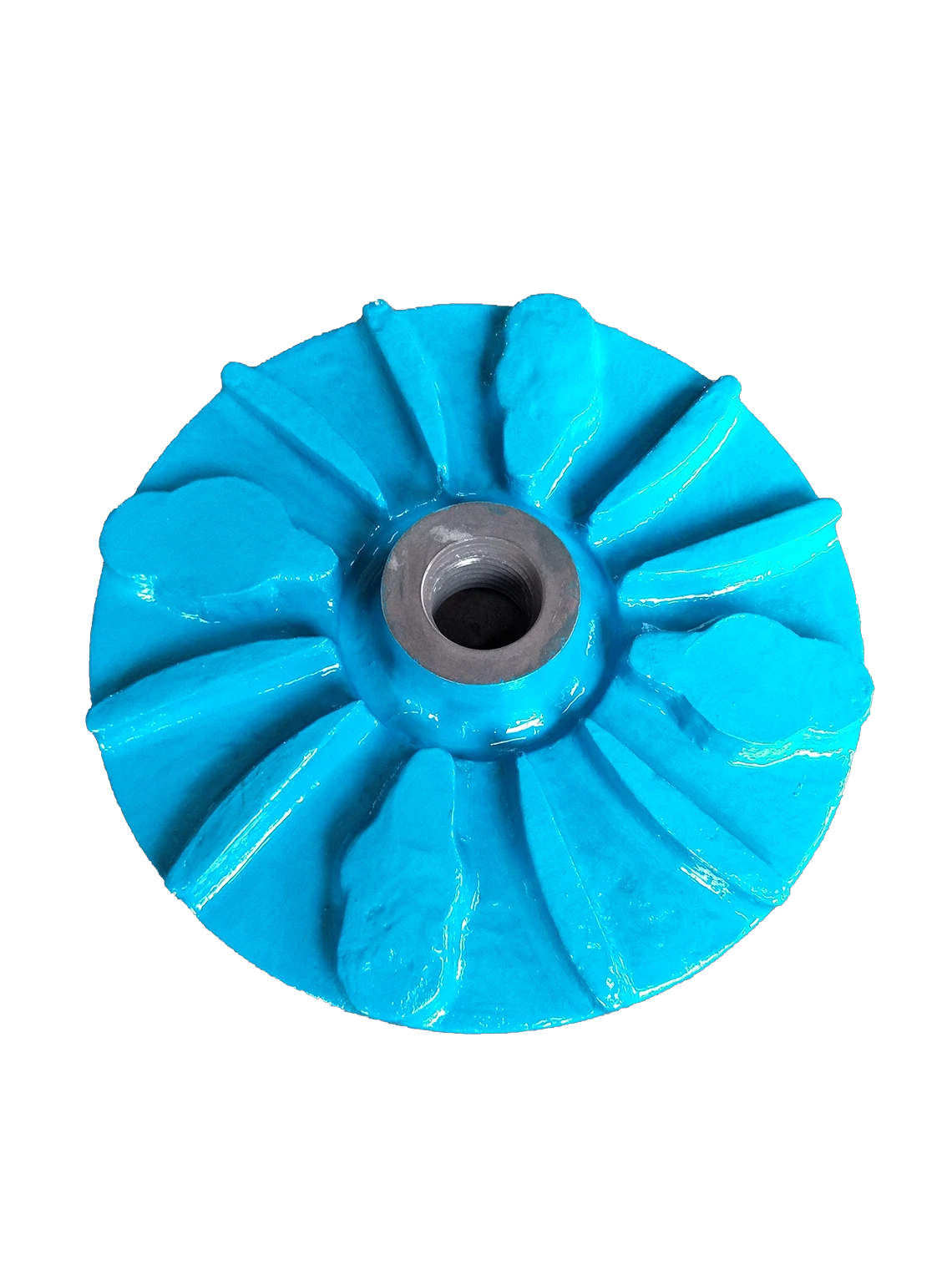

Pump Wear Parts FH4147 Metal

In the industrial world, a slurry pump plays an invaluable role, yet their workings often remain a mystery for those outside specialized sectors. Understanding how a slurry pump functions can offer insights not only into its operational efficiency but also into selecting the right equipment for your specific needs. By diving into the technical aspects and practical applications of slurry pumps, this comprehensive guide unravels their complexities with a focus on real-world experience, professional expertise, authoritative insights, and robust trustworthiness.

Real-world application of slurry pumps showcases their adaptability and necessity. In mining operations, for example, these pumps are often deployed to move tailings or mineral concentrates. The choice between a horizontal or vertical slurry pump can significantly impact the operational efficiency and cost. Horizontal pumps are generally favored for high-flow applications, while vertical pumps are suited for those involving smaller floor spaces or sumps. Expertise in selecting and maintaining slurry pumps can greatly enhance operational output and longevity. For example, a nuanced understanding of pump curve readings — which graphically represent a pump's performance by detailing the relationship between flow rate and pressure head — is crucial in engineering tasks. Misreading or misapplying this data can lead not only to suboptimal performance but also to premature equipment failure. From an authoritative standpoint, acknowledging global standards such as those from the Hydraulic Institute or ISO can guide proper pump selection, ensuring compatibility and safety across international industrial practices. These standards provide detailed guidelines on everything from pump construction to testing methodologies, reinforcing the trustworthiness of slurry pump operations and procurement. Long-term reliability of slurry pumps is often secured through rigorous maintenance schedules, emphasizing regular inspections and parts replacement. Proactive approaches in monitoring wear rates of components such as the impeller and casing lining can preempt costly downtimes. Cutting-edge technologies like predictive maintenance and real-time monitoring systems now play pivotal roles, alerting operators to potential issues before they escalate. In summary, understanding how a slurry pump works requires a blend of technical knowledge and practical insight. From grasping the nuances of centrifugal mechanisms and optimal sealing solutions to leveraging performance curves and adhering to industry standards, the effective deployment and maintenance of slurry pumps hinge on expertise and trustworthiness. Whether in mining, wastewater management, or chemical processing, these pumps remain indispensable, ensuring smooth, efficient, and safe operations across industries.

Real-world application of slurry pumps showcases their adaptability and necessity. In mining operations, for example, these pumps are often deployed to move tailings or mineral concentrates. The choice between a horizontal or vertical slurry pump can significantly impact the operational efficiency and cost. Horizontal pumps are generally favored for high-flow applications, while vertical pumps are suited for those involving smaller floor spaces or sumps. Expertise in selecting and maintaining slurry pumps can greatly enhance operational output and longevity. For example, a nuanced understanding of pump curve readings — which graphically represent a pump's performance by detailing the relationship between flow rate and pressure head — is crucial in engineering tasks. Misreading or misapplying this data can lead not only to suboptimal performance but also to premature equipment failure. From an authoritative standpoint, acknowledging global standards such as those from the Hydraulic Institute or ISO can guide proper pump selection, ensuring compatibility and safety across international industrial practices. These standards provide detailed guidelines on everything from pump construction to testing methodologies, reinforcing the trustworthiness of slurry pump operations and procurement. Long-term reliability of slurry pumps is often secured through rigorous maintenance schedules, emphasizing regular inspections and parts replacement. Proactive approaches in monitoring wear rates of components such as the impeller and casing lining can preempt costly downtimes. Cutting-edge technologies like predictive maintenance and real-time monitoring systems now play pivotal roles, alerting operators to potential issues before they escalate. In summary, understanding how a slurry pump works requires a blend of technical knowledge and practical insight. From grasping the nuances of centrifugal mechanisms and optimal sealing solutions to leveraging performance curves and adhering to industry standards, the effective deployment and maintenance of slurry pumps hinge on expertise and trustworthiness. Whether in mining, wastewater management, or chemical processing, these pumps remain indispensable, ensuring smooth, efficient, and safe operations across industries.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024