-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

3 月 . 06, 2025 15:47

Back to list

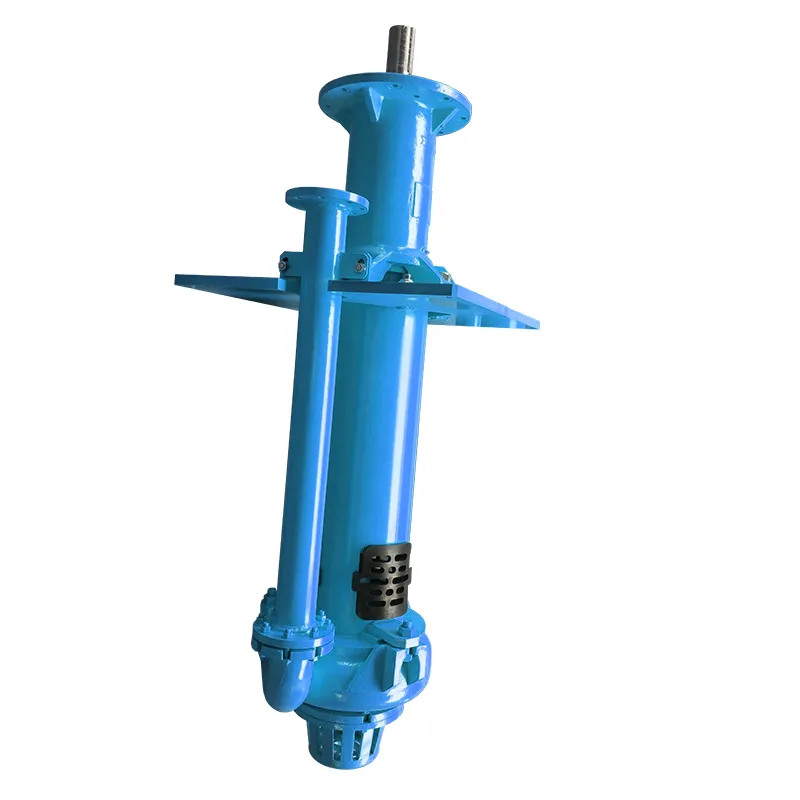

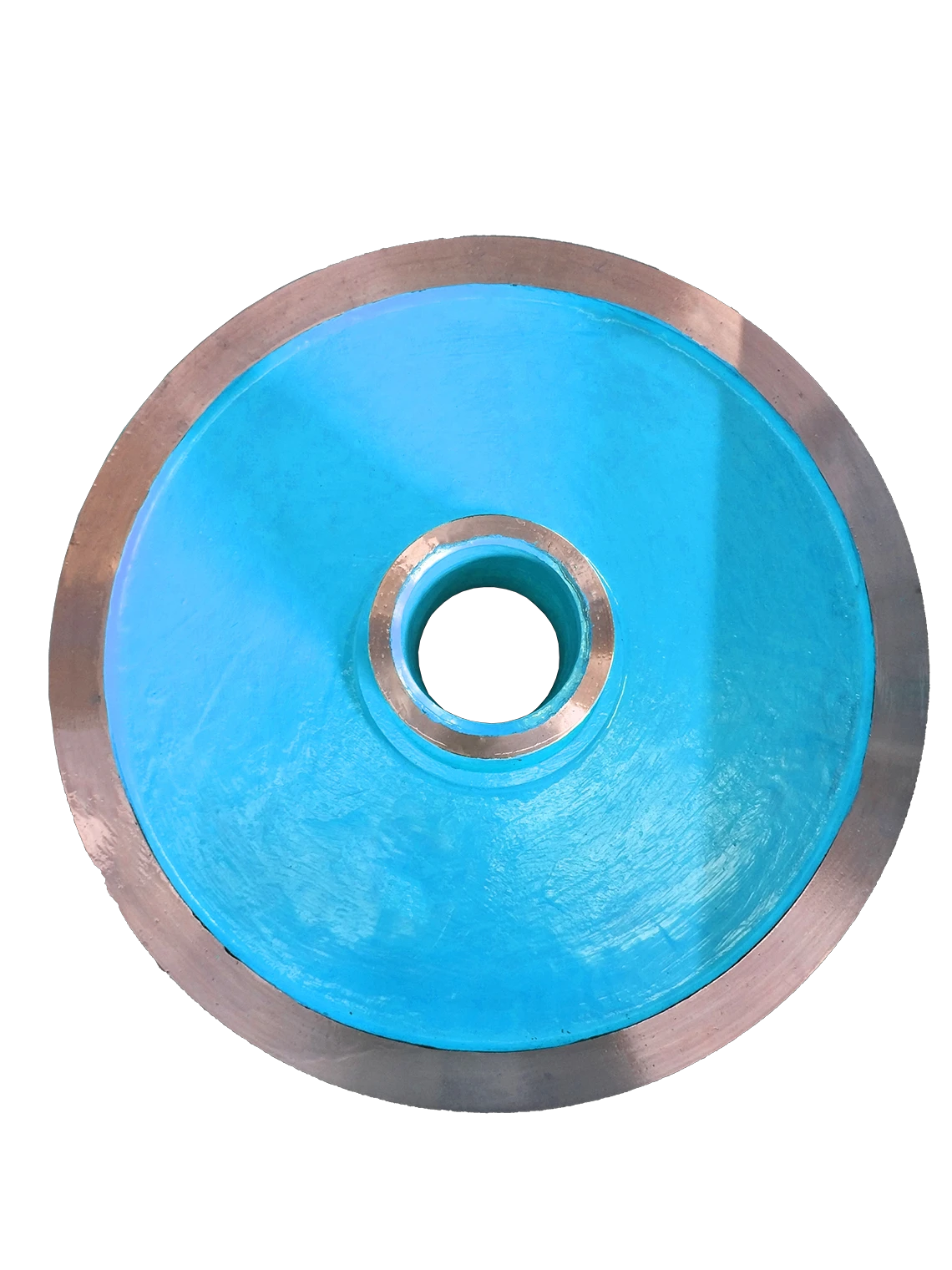

Pump Wear Parts TC4191 Metal

Slurry pumps are essential components in industries dealing with the transportation of fluids with suspended solids, such as mining, wastewater treatment, and oil sands processing. The correct specification of slurry pumps can drastically enhance operational efficiency and reduce maintenance costs. Choosing the right slurry pump involves understanding the flow characteristics of the slurry, the corrosive environment, and the abrasive nature of the solid particles involved.

Another important consideration is the pump's ability to handle solid particles without clogging or damage. This is determined by the pump's solids handling capability, represented by parameters such as solid passing sphere size. A pump capable of handling large solids without losing efficiency is vital in environments like mining, where debris and large particulate matter are common. Operational safety and ease of maintenance are crucial aspects of slurry pump specification. The design should allow for easy access to components that wear over time, like impellers and liners, reducing downtime during maintenance. Safety features such as pressure relief valves and monitoring systems should be considered to protect both the equipment and the operators from unexpected scenarios, such as overpressure or leakage. In addition to the technical specifications, the pump's operational history and manufacturer's reputation are significant. Manufacturers with a proven track record of reliability and customer support can provide assurance in long-term performance and availability of spare parts. Third-party certifications and industry-standard compliance also offer peace of mind that the equipment meets necessary safety and quality benchmarks. Lastly, incorporating advanced technologies such as predictive maintenance and remote monitoring helps in the early detection of wear and tear, preemptively addressing issues before they culminate in significant damage or system downtime. This not only saves on repair costs but also ensures smooth and continuous operations. In conclusion, the specification of slurry pumps must be approached with comprehensive knowledge of the operational demands and environmental circumstances. Through a meticulous evaluation of slurry characteristics, material selection, pump configuration, and the manufacturer's reputation, industries can achieve efficient and cost-effective fluid handling solutions tailored to their specific requirements.

Another important consideration is the pump's ability to handle solid particles without clogging or damage. This is determined by the pump's solids handling capability, represented by parameters such as solid passing sphere size. A pump capable of handling large solids without losing efficiency is vital in environments like mining, where debris and large particulate matter are common. Operational safety and ease of maintenance are crucial aspects of slurry pump specification. The design should allow for easy access to components that wear over time, like impellers and liners, reducing downtime during maintenance. Safety features such as pressure relief valves and monitoring systems should be considered to protect both the equipment and the operators from unexpected scenarios, such as overpressure or leakage. In addition to the technical specifications, the pump's operational history and manufacturer's reputation are significant. Manufacturers with a proven track record of reliability and customer support can provide assurance in long-term performance and availability of spare parts. Third-party certifications and industry-standard compliance also offer peace of mind that the equipment meets necessary safety and quality benchmarks. Lastly, incorporating advanced technologies such as predictive maintenance and remote monitoring helps in the early detection of wear and tear, preemptively addressing issues before they culminate in significant damage or system downtime. This not only saves on repair costs but also ensures smooth and continuous operations. In conclusion, the specification of slurry pumps must be approached with comprehensive knowledge of the operational demands and environmental circumstances. Through a meticulous evaluation of slurry characteristics, material selection, pump configuration, and the manufacturer's reputation, industries can achieve efficient and cost-effective fluid handling solutions tailored to their specific requirements.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024