-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 08, 2025 06:58

Back to list

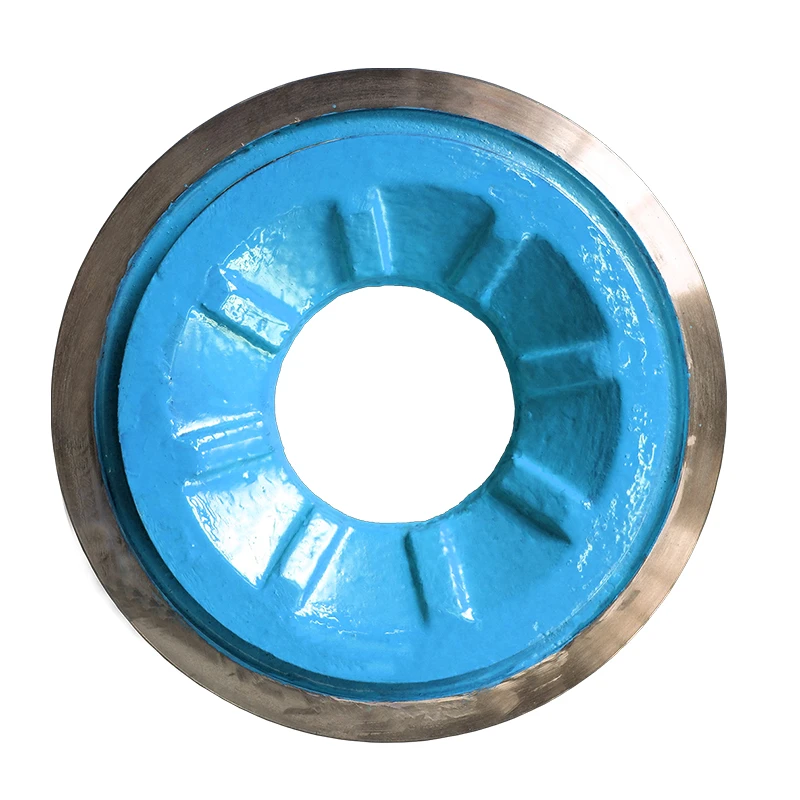

wet pump parts

Wet pump parts are integral components in various industries, especially those that involve fluid management. These parts ensure that pumps operate efficiently and effectively, thus prolonging the lifespan of the equipment and ensuring consistent performance. Selecting the right wet pump parts is crucial for industries ranging from water treatment to chemical processing and beyond.

When discussing authoritativeness, partnering with recognized experts in wet pump parts is beneficial. Industry leaders with a reputable history of producing high-quality components provide a reassurance of reliability. These companies often offer comprehensive warranties and post-purchase support, such as installation guidance and routine maintenance checks. This not only enhances trust but also adds a layer of security for businesses investing in wet pump systems. Finally, trustworthiness is vital when sourcing wet pump parts. This is often built through certifications and adherence to international standards. Certifications such as ISO 9001 for quality management are a testament to a company’s commitment to producing consistently high-quality products. OEM (Original Equipment Manufacturer) partnerships also enhance credibility, as these partnerships ensure that replacement parts match the original specifications and performance. The procurement of wet pump parts is not simply a transaction but a partnership. Reliable suppliers invest time in understanding the specific needs of their clients, providing customized solutions that best suit their operational requirements. Through thorough consultation, businesses receive tailored recommendations that take into account the types of fluids being pumped, the environmental conditions, and the long-term performance goals. In conclusion, the nuances of wet pump parts demand a blend of experience, expertise, authoritativeness, and trustworthiness. By focusing on these aspects, industries can optimize their pump operations, leading to improved efficiency, reduced costs, and enhanced sustainability. Engaging with knowledgeable manufacturers and suppliers is crucial to achieving these objectives, ensuring that each component supports the overall functionality and durability of pump systems. This consistent attention to quality and practicality empowers companies to maintain seamless operations, regardless of the complexities of their fluid management needs.

When discussing authoritativeness, partnering with recognized experts in wet pump parts is beneficial. Industry leaders with a reputable history of producing high-quality components provide a reassurance of reliability. These companies often offer comprehensive warranties and post-purchase support, such as installation guidance and routine maintenance checks. This not only enhances trust but also adds a layer of security for businesses investing in wet pump systems. Finally, trustworthiness is vital when sourcing wet pump parts. This is often built through certifications and adherence to international standards. Certifications such as ISO 9001 for quality management are a testament to a company’s commitment to producing consistently high-quality products. OEM (Original Equipment Manufacturer) partnerships also enhance credibility, as these partnerships ensure that replacement parts match the original specifications and performance. The procurement of wet pump parts is not simply a transaction but a partnership. Reliable suppliers invest time in understanding the specific needs of their clients, providing customized solutions that best suit their operational requirements. Through thorough consultation, businesses receive tailored recommendations that take into account the types of fluids being pumped, the environmental conditions, and the long-term performance goals. In conclusion, the nuances of wet pump parts demand a blend of experience, expertise, authoritativeness, and trustworthiness. By focusing on these aspects, industries can optimize their pump operations, leading to improved efficiency, reduced costs, and enhanced sustainability. Engaging with knowledgeable manufacturers and suppliers is crucial to achieving these objectives, ensuring that each component supports the overall functionality and durability of pump systems. This consistent attention to quality and practicality empowers companies to maintain seamless operations, regardless of the complexities of their fluid management needs.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024