-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 08, 2025 06:36

Back to list

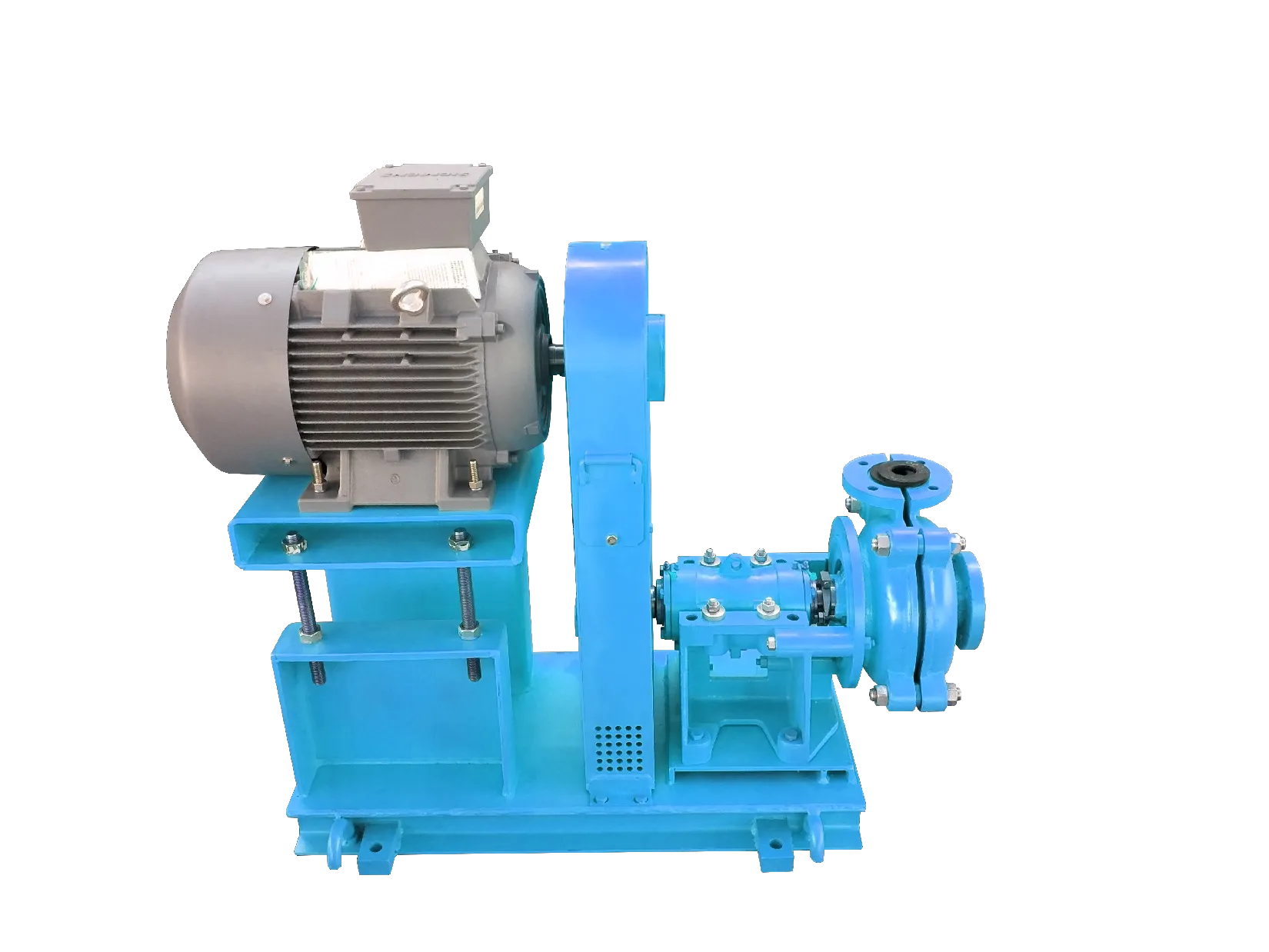

wet end pump parts

In the dynamic world of industrial machinery, the performance and longevity of equipment rely significantly on the quality of its components. Among these, wet end pump parts play a critical role, especially in sectors involving fluid management such as chemical processing, water treatment, and pulp and paper industries. Selecting the right parts can enhance efficiency, reduce downtime, and save costs. Through insights grounded in experience and expertise, we delve into the significance, variety, and maintenance of wet end pump parts to offer actionable solutions.

The authority of a brand or manufacturer in the wet end pump parts market is often established through a track record of technical advancements and rigorous testing methodologies. Companies investing in research continuously push the envelope on material science, offering products with superior resistance to abrasion and erosion. Networking with certified professionals who have demonstrated reliability and quality can significantly impact maintenance costs and machinery turnover rates. Trustworthiness in wet end pump parts is built on consistent performance over time, backed by comprehensive warranty and support services. Ethical manufacturers uphold transparency, welcoming audits and providing certifications of authenticity and compliance for their components. As part of ongoing maintenance strategies, frequent monitoring and timely replacement of parts, such as seals and wear rings, are recommended. This pre-emptive approach reduces the risk of unexpected failures and fosters a culture of preventative maintenance. An often overlooked aspect is the environmental impact of wet end pump parts. Embracing eco-friendly practices and advancing towards sustainable product lines not only benefits the planet but also aligns with stringent environmental policies. Thus, choosing parts with a minimal carbon footprint or those made from recyclable materials can enhance a company’s reputation and operational ethos. In conclusion, the significance of selecting high-quality wet end pump parts extends beyond immediate functional needs. By leveraging expertise, engaging with authoritative sources, and fostering trust through dependable products and services, industries can navigate the complexities of fluid management with confidence. Prioritizing innovative, precise, and sustainable solutions ensures equipment longevity, operational efficiency, and a resilient bottom line. Wet end pump parts are not just cogwheels in a machine but pivotal components in achieving industrial excellence and environmental stewardship.

The authority of a brand or manufacturer in the wet end pump parts market is often established through a track record of technical advancements and rigorous testing methodologies. Companies investing in research continuously push the envelope on material science, offering products with superior resistance to abrasion and erosion. Networking with certified professionals who have demonstrated reliability and quality can significantly impact maintenance costs and machinery turnover rates. Trustworthiness in wet end pump parts is built on consistent performance over time, backed by comprehensive warranty and support services. Ethical manufacturers uphold transparency, welcoming audits and providing certifications of authenticity and compliance for their components. As part of ongoing maintenance strategies, frequent monitoring and timely replacement of parts, such as seals and wear rings, are recommended. This pre-emptive approach reduces the risk of unexpected failures and fosters a culture of preventative maintenance. An often overlooked aspect is the environmental impact of wet end pump parts. Embracing eco-friendly practices and advancing towards sustainable product lines not only benefits the planet but also aligns with stringent environmental policies. Thus, choosing parts with a minimal carbon footprint or those made from recyclable materials can enhance a company’s reputation and operational ethos. In conclusion, the significance of selecting high-quality wet end pump parts extends beyond immediate functional needs. By leveraging expertise, engaging with authoritative sources, and fostering trust through dependable products and services, industries can navigate the complexities of fluid management with confidence. Prioritizing innovative, precise, and sustainable solutions ensures equipment longevity, operational efficiency, and a resilient bottom line. Wet end pump parts are not just cogwheels in a machine but pivotal components in achieving industrial excellence and environmental stewardship.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024