-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 08, 2025 06:12

Back to list

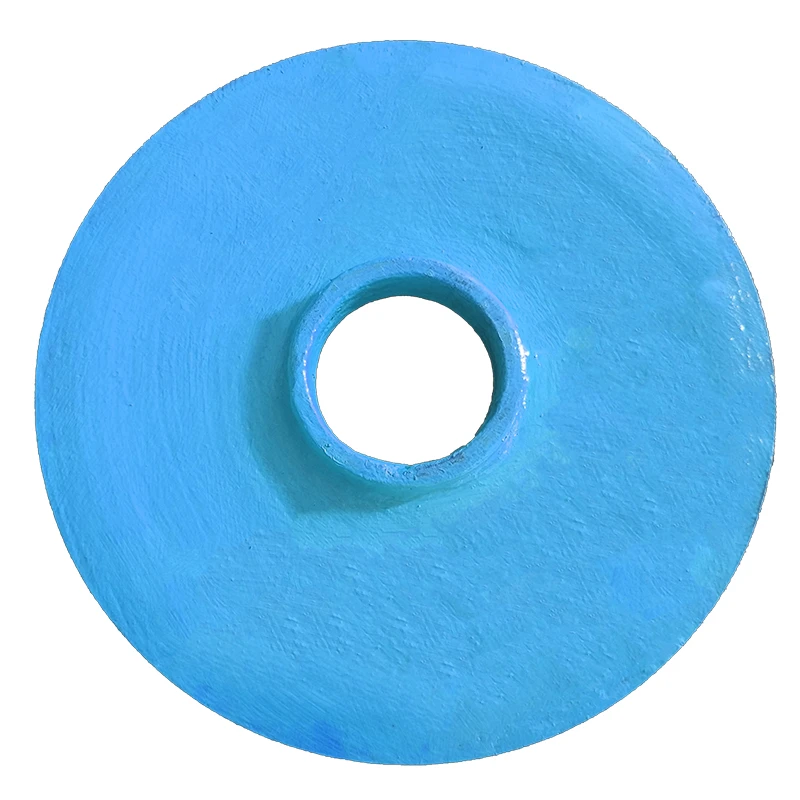

wet parts

Navigating the world of industrial and mechanical products can be challenging, and when it comes to specific components like wet parts, the complexity can increase. Wet parts refer to components within pumps or other machinery that come into contact with liquid during operation. Understanding the intricacies of these components is crucial, especially if your business depends on machinery efficiency and longevity. In this article, we delve deep into the world of wet parts, covering insights from experienced professionals and combining authoritative sources to bring forth a comprehensive understanding.

Innovative technologies are reshaping the future of wet parts manufacturing. Additive manufacturing, commonly referred to as 3D printing, stands at the forefront of this transformation. This tech not only allows for rapid prototyping but also customization of wet parts to cater to specific industry needs, enhancing the adaptability and performance of mechanical systems. Additionally, AI-driven simulations now enable engineers to predict the behavior of wet parts under varying operational conditions, allowing for the creation of optimized, failure-resistant designs before physical testing. As industries progress, the emphasis on reliability and sustainability continues to evolve. Smart sensors are becoming increasingly prevalent, providing real-time data on the performance of wet parts during operation. This technology enhances predictive maintenance strategies, vastly reducing unplanned downtimes and extending the service life of machinery. In conclusion, the multifaceted nature of wet parts encompasses materials science, adherence to industry standards, and the integration of cutting-edge technology. It is imperative for businesses to make informed decisions based on expertise, industry standards, and forward-thinking technological applications. Companies that prioritize these elements not only secure a competitive edge but also align with the evolving demands of an industrious world striving for sustainability and efficiency. Selecting the right wet parts is not just about operational necessity; it's about forging a reliable pathway in the uncharted territories of industrial growth and technological advancement. By leveraging informed choices and trusted partnerships, businesses can secure their place at the forefront of innovation and efficiency.

Innovative technologies are reshaping the future of wet parts manufacturing. Additive manufacturing, commonly referred to as 3D printing, stands at the forefront of this transformation. This tech not only allows for rapid prototyping but also customization of wet parts to cater to specific industry needs, enhancing the adaptability and performance of mechanical systems. Additionally, AI-driven simulations now enable engineers to predict the behavior of wet parts under varying operational conditions, allowing for the creation of optimized, failure-resistant designs before physical testing. As industries progress, the emphasis on reliability and sustainability continues to evolve. Smart sensors are becoming increasingly prevalent, providing real-time data on the performance of wet parts during operation. This technology enhances predictive maintenance strategies, vastly reducing unplanned downtimes and extending the service life of machinery. In conclusion, the multifaceted nature of wet parts encompasses materials science, adherence to industry standards, and the integration of cutting-edge technology. It is imperative for businesses to make informed decisions based on expertise, industry standards, and forward-thinking technological applications. Companies that prioritize these elements not only secure a competitive edge but also align with the evolving demands of an industrious world striving for sustainability and efficiency. Selecting the right wet parts is not just about operational necessity; it's about forging a reliable pathway in the uncharted territories of industrial growth and technological advancement. By leveraging informed choices and trusted partnerships, businesses can secure their place at the forefront of innovation and efficiency.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024