-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 08, 2025 07:26

Back to list

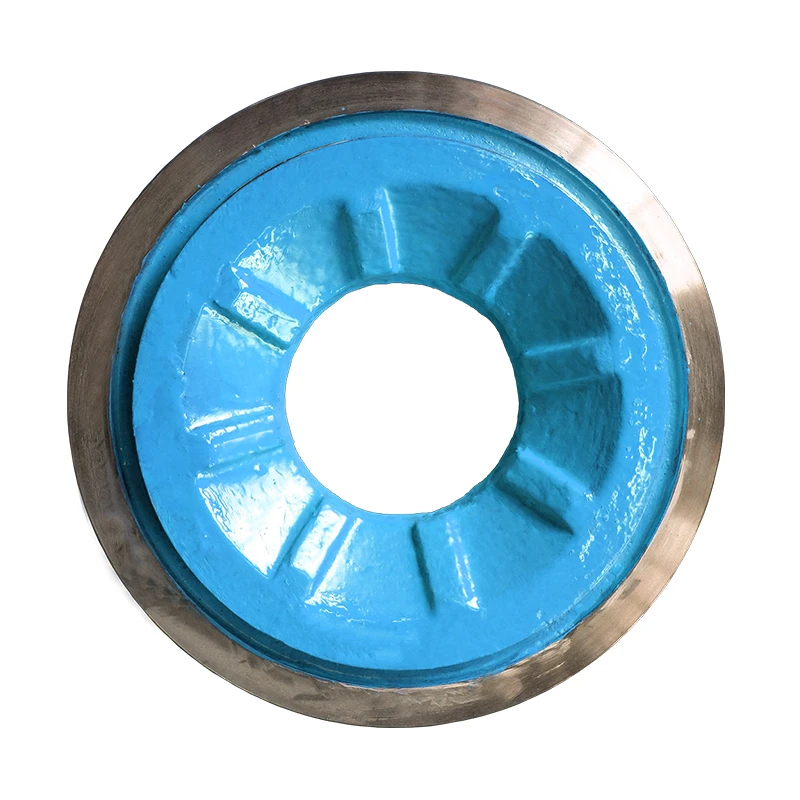

waterway wet end pump parts

Understanding the intricacies involved in the maintenance and operation of waterway wet end pump parts is crucial for professionals in industries reliant on these essential components. As someone who has spent years in the field, meticulously working with these parts, I'm here to shed light on their significance, structure, and the best practices for procuring and maintaining these integral pieces of equipment.

Employing and sourcing these parts from reputable manufacturers and suppliers is an aspect that cannot be overlooked. A manufacturer’s reputation, adherence to industry standards, and their commitment to innovation in materials and design directly impact the performance and reliability of wet end pump systems. It’s advisable to choose suppliers who not only provide high-quality parts but also offer comprehensive support, including installation guidance and after-sales service. From an expertise perspective, regular inspection and maintenance schedules are vital in ensuring that the pump parts remain in prime condition. Scheduled maintenance helps identify the wear on critical components, such as impellers, seals, and bearings, allowing for timely replacements or repairs, thus averting potential failures that could cause costly downtimes or amplify operational risks. For instance, vibration analysis or thermal imaging might be employed to detect anomalies early, offering a proactive approach to maintenance. Furthermore, embracing technological advancements such as digital twin technology, where a digital replica of the pump system is maintained, aids in predicting potential failures and streamlining the maintenance process. Such predictive maintenance approaches significantly enhance both reliability and performance, presenting a leap forward from traditional maintenance strategies. With the rapid pace of technological and material advances, staying informed about the latest trends and innovations in waterway wet end pump parts is imperative. Engaging with industry forums, subscribing to technical journals, and attending relevant workshops and seminars not only boosts expertise but also enhances the trustworthiness of professionals dealing with these components in any business setting. In conclusion, when dealing with waterway wet end pump parts, it is essential to blend practical experience with technical expertise to maintain operational efficacy. By focusing on quality components, regular maintenance, and staying abreast of technological progressions, companies can ensure their pump systems operate smoothly, ultimately solidifying their competitive edge and reinforcing their authority in the industry. This balanced approach guarantees that systems remain reliable and efficient, adding significant value to the enterprises that rely on these crucial components.

Employing and sourcing these parts from reputable manufacturers and suppliers is an aspect that cannot be overlooked. A manufacturer’s reputation, adherence to industry standards, and their commitment to innovation in materials and design directly impact the performance and reliability of wet end pump systems. It’s advisable to choose suppliers who not only provide high-quality parts but also offer comprehensive support, including installation guidance and after-sales service. From an expertise perspective, regular inspection and maintenance schedules are vital in ensuring that the pump parts remain in prime condition. Scheduled maintenance helps identify the wear on critical components, such as impellers, seals, and bearings, allowing for timely replacements or repairs, thus averting potential failures that could cause costly downtimes or amplify operational risks. For instance, vibration analysis or thermal imaging might be employed to detect anomalies early, offering a proactive approach to maintenance. Furthermore, embracing technological advancements such as digital twin technology, where a digital replica of the pump system is maintained, aids in predicting potential failures and streamlining the maintenance process. Such predictive maintenance approaches significantly enhance both reliability and performance, presenting a leap forward from traditional maintenance strategies. With the rapid pace of technological and material advances, staying informed about the latest trends and innovations in waterway wet end pump parts is imperative. Engaging with industry forums, subscribing to technical journals, and attending relevant workshops and seminars not only boosts expertise but also enhances the trustworthiness of professionals dealing with these components in any business setting. In conclusion, when dealing with waterway wet end pump parts, it is essential to blend practical experience with technical expertise to maintain operational efficacy. By focusing on quality components, regular maintenance, and staying abreast of technological progressions, companies can ensure their pump systems operate smoothly, ultimately solidifying their competitive edge and reinforcing their authority in the industry. This balanced approach guarantees that systems remain reliable and efficient, adding significant value to the enterprises that rely on these crucial components.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024