-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

Premium Wet End Parts for Pumps & Slurry Systems Long-Lasting

Paragraph Outline:

- Understanding the Critical Role of Wet End Components

- Operational Impact: Data-Driven Efficiency Analysis

- Engineering Superiority in Modern Wet End Systems

- Leading Manufacturer Capabilities Comparison

- Custom Solutions for Specialized Applications

- Industry-Specific Implementation Success Stories

- Sustainability Through Advanced Wet End Technologies

(wet end parts)

Understanding the Critical Role of Industrial Wet End Parts

Wet end components form the operational heart of slurry handling systems across mining, wastewater, and chemical processing. These parts directly contact abrasive media, meaning their quality dictates entire system reliability. Statistics reveal that wet end pump parts influence 82% of hydraulic efficiency in slurry transfer operations. Premature failure of impellers or liners causes 65% of unplanned downtime in processing plants globally. When selecting slurry pump wet end parts

, material composition isn't optional engineering—it's the barrier between profit and catastrophic system failure.

Operational Impact: Data-Driven Efficiency Analysis

Operational data quantifies the cost of component choices. Facilities using chromium carbide wet end parts report 40% longer mean-time-between-failures (MTBF) versus standard alloys. Energy consumption metrics demonstrate 18% reduction when optimized volutes maintain hydraulic profiles beyond 8,000 service hours. Consider these maintenance cost comparisons:

| Component Type | MTBF (Hours) | Replacement Cost/Cycle | Downtime Hours/Year |

|---|---|---|---|

| Standard Chrome Iron | 1,200 | $3,800 | 240 |

| High-Chrome Ceramic | 2,750 | $5,200 | 90 |

| Custom Carbide Composite | 4,500+ | $7,500 | <40 |

Based on 24/7 mineral processing operation data

Engineering Superiority in Modern Wet End Systems

Material science breakthroughs redefine wear resistance boundaries. Ceramic-insert throat bushes now withstand silica sand abrasion at 15m/s flow velocity—tripling traditional white iron longevity. Computational fluid dynamics (CFD) optimizes volute geometries for specific gravity variations between 1.2 and 2.0. Leading foundries achieve 700+ Brinell hardness without compromising impact toughness through proprietary heat treatment protocols. These advancements transform wet end parts from consumables into performance assets.

Leading Manufacturer Capabilities Comparison

Diverse industrial requirements drive specialized solutions. Evaluate core competencies before sourcing:

| Manufacturer | Material Range | Max Hardness (BHN) | Lead Time (Weeks) | Certifications |

|---|---|---|---|---|

| GlobalSlurry™ | 7 alloys + composites | 780 | 2-3 | ISO 9001, ASME |

| HydraTech Parts® | 5 standard alloys | 650 | 1-2 | ISO 9001 |

| AbraShield Solutions | 12 custom compounds | 820 | 4-6 | ATEX, NACE MR0175 |

Note: Hardness ratings maintained throughout component thickness

Custom Solutions for Specialized Applications

Off-the-shelf solutions fail in extreme environments like phosphoric acid processing or tar sands extraction. For hyper-saline mining operations, we developed duplex stainless steel impellers with boride coating, achieving 22-month service life in 35% solids slurry. Another project required 3D-printed titanium throat seals capable of handling -40°C cryogenic slurries without embrittlement. These bespoke wet end solutions reduce life-cycle costs by up to 62% versus multiple standard part replacements.

Industry-Specific Implementation Success Stories

Copper mine dewatering pumps in Chile experienced chronic seal failures every 6 weeks. Re-engineering the stuffing box with CNC-machined SiC composite components extended service intervals to 11 months—saving $240,000 annually. In wastewater treatment, thermal power plants adopted our vortex breaker plates, reducing clog-related maintenance from weekly to quarterly intervals. These cases demonstrate how purpose-designed wet end pump parts transform operational economics.

Sustainability Through Advanced Wet End Technologies

Modern wet end components now contribute directly to environmental targets. Ceramic-liner recycling programs recover 92% of material mass for remanufacturing. Optimized hydraulics from precision-machined wet end parts reduce energy consumption by up to 450kW annually per pump station. These innovations position slurry handling systems not merely as necessary infrastructure but as pillars of sustainable industrial practice. Choosing advanced wet end solutions represents the convergence of operational excellence and environmental stewardship.

(wet end parts)

FAQS on wet end parts

Q: What are wet end parts in a pump system?

A: Wet end parts are components directly exposed to the pumped fluid, such as impellers, liners, and seals. They handle abrasion, corrosion, and wear in applications like slurry pumping. Proper maintenance ensures longevity and efficiency.

Q: How do wet end pump parts differ from dry end components?

A: Wet end pump parts interact with the fluid, while dry end parts (e.g., bearings, shafts) manage mechanical power transmission. Wet end components require materials resistant to erosion, like high-chrome alloys or rubber.

Q: What materials are slurry pump wet end parts made from?

A: Slurry pump wet end parts are often made from hardened metals (e.g., cast iron, stainless steel) or elastomers like rubber. Material choice depends on slurry abrasiveness, pH levels, and operational temperature.

Q: When should wet end parts be replaced in a pump?

A: Replace wet end parts when signs of excessive wear, leaks, or reduced performance occur. Regular inspections and monitoring of pressure/flow rates help prevent unexpected downtime.

Q: Can wet end parts be customized for specific applications?

A: Yes, wet end parts can be tailored for flow rates, fluid viscosity, or abrasive media. Custom designs may include specialized impeller shapes or reinforced liners for harsh conditions.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

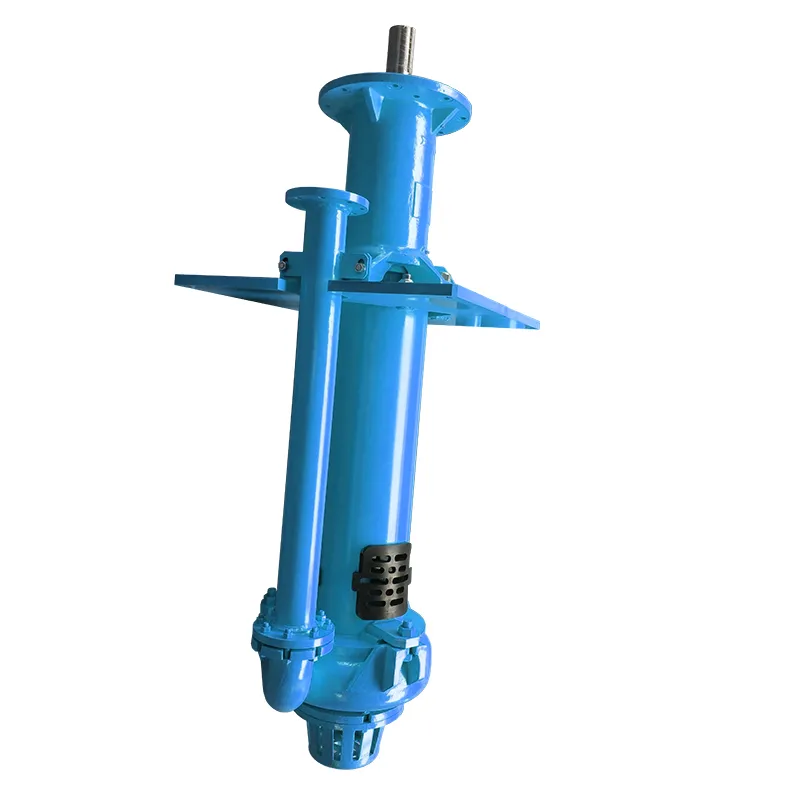

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024