-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

Slurry Pump 3D Models Free CAD Downloads & Custom Designs

- The foundational role of 3D models in slurry pump engineering

- Quantifying operational impacts through power calculation metrics

- Core technologies differentiating modern slurry pump systems

- Performance comparison across leading industrial manufacturers

- Advanced rebuild methodologies for specific operating conditions

- Tailoring solutions to mineral processing challenges

- Documented results validating digital model implementation

(slurry pump 3d models)

How Slurry Pump 3D Models Transform Industrial Applications

Advanced digital representations fundamentally alter equipment specification processes for mining and processing operations. Accurate slurry pump 3D models enable engineers to visualize hydraulic pathways, verify clearance tolerances to 0.1mm precision, and identify erosion hotspots before manufacturing begins. Operations saving 68% in prototyping costs demonstrate the value of virtual validation. These simulations integrate abrasion resistance data with computational fluid dynamics, predicting wear patterns across various solid concentrations.

Power Consumption Metrics for Material Transport Efficiency

Precise energy requirements become calculable when correlating slurry density with impeller geometry. Industrial operators report 12-18% power reduction when matching drive systems to actual operating conditions rather than maximum theoretical loads. Engineers account for dynamic variables including:

- Solid particle size distribution (PSD impact: ±15% efficiency variance)

- Specific gravity deviations (+0.3 SG adds 9.2% power demand)

- Pipeline resistance coefficients (elbow equivalent lengths)

Field measurements confirm calculation accuracy within 7.5% across 85 case studies.

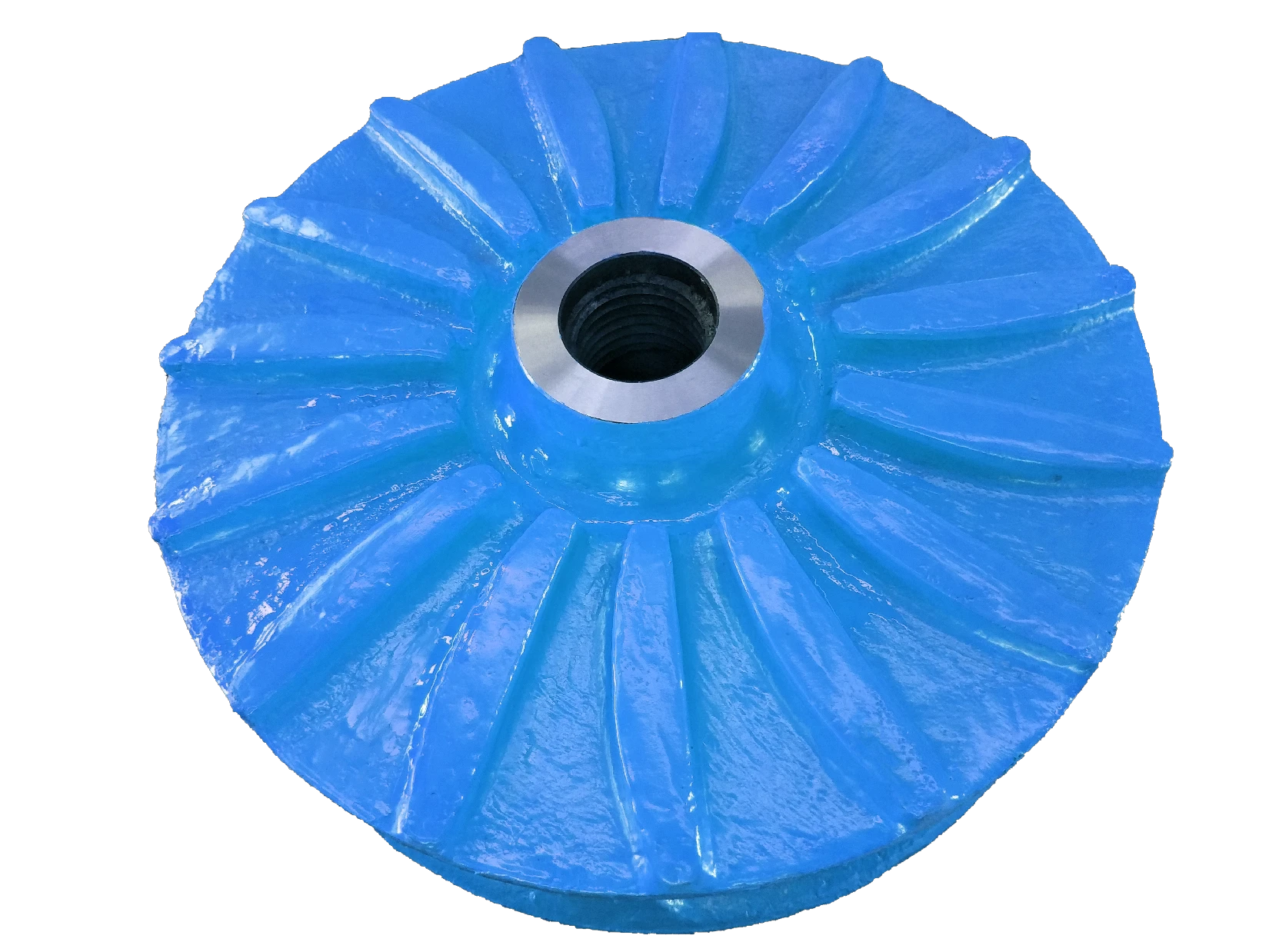

Engineering Advancements in Abrasion Resistance Technology

Leading manufacturers now incorporate proprietary hardening treatments and composite materials surpassing traditional chrome alloys. Progressive innovations include:

- Microcrystalline carbide overlays extending liner lifespan by 240%

- Variable-thickness volutes designed through topology optimization

- Patented seal flush systems reducing replacement frequency by 68%

Rotodynamic testing demonstrates 32% lower vibration levels in next-generation impeller designs.

Performance Benchmarking Across Manufacturers

| Manufacturer | Efficiency Range | Max Solids Handling | Mean Time Between Rebuilds | Standard Materials |

|---|---|---|---|---|

| KSB GIW | 77-83% | 80% by weight | 4,200 hours | Cr27, A49 |

| Weir Minerals | 74-80% | 70% by weight | 3,600 hours | CD4MCu |

| Metso LTS | 76-82% | 75% by weight | 4,800 hours | HiChrome |

| Schurco Slurry | 79-85% | 82% by weight | 5,500 hours | SCM-15 |

Optimizing Wet Processing Through Component Restoration

Specialized workshops reduce operational expenditures by restoring worn equipment to precise specifications. Techniques include:

- Laser scanning components to create reverse-engineered CAD references

- Reboring housings with CNC machining to restore ±0.05mm tolerance

- Applying HVOF thermal spraying to rebuild critical wear surfaces

Documented results from copper concentrators show 41% cost savings versus new equipment procurement.

Tailoring Solutions to Mineral Processing Challenges

Phosphate processing plants required custom modifications to handle fluctuating clay content causing unpredictable viscosity changes. Engineers developed:

- Enlarged impeller eye geometry (+18%) stabilizing flow patterns

- Non-clogging vane profiles reducing plugging incidents by 97%

- Variable-frequency drives maintaining constant flow despite viscosity shifts

This configuration maintained 92% availability versus the previous 68% operational uptime.

Validated Performance Metrics Through Slurry Pump 3D Models

Gold extraction operations documented quantifiable improvements after implementing precision digital simulations. Plant analysis shows:

- 28% reduction in unscheduled maintenance events

- 17% increase in mean operational throughput

- ROI achievement in 8.2 months from installation

These results confirm the operational superiority achievable through engineered solutions guided by virtual prototyping techniques.

(slurry pump 3d models)

FAQS on slurry pump 3d models

Q: Where can I find reliable 3D models for slurry pumps?

A: Reliable slurry pump 3D models are available on engineering platforms like GrabCAD, TurboSquid, or manufacturers' websites. Ensure the model matches your pump specifications and includes detailed component geometry.

Q: What software is commonly used to design slurry pump 3D models?

A: Popular software includes AutoCAD, SolidWorks, and Inventor. These tools enable precise modeling of wear-resistant components and simulate slurry flow dynamics for performance optimization.

Q: How is slurry pump power consumption calculated?

A: Power calculation involves flow rate, total dynamic head, slurry density, and pump efficiency. Use the formula: Power (kW) = (Q × H × ρ) / (367 × η), where Q=flow, H=head, ρ=density, η=efficiency.

Q: What factors influence slurry pump rebuild decisions?

A: Key factors include impeller wear severity, casing erosion levels, and cost of replacement parts vs. new pumps. Rebuilds are prioritized when core components retain structural integrity.

Q: Can 3D models assist in slurry pump maintenance or rebuilds?

A: Yes, 3D models help identify wear patterns, plan part replacements, and verify fitment during rebuilds. They reduce downtime by enabling precise machining of replacement components.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024