-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

High Chrome Slurry Pump - Durable A05 Volute Liner & China OEM

- The Industrial Challenge: Slurry Pumping in Extreme Conditions

- Material Science Behind High-Chrome Superiority

- Cutting-Edge Engineering Features Explained

- Manufacturer Comparison: Performance Metrics

- Tailored Solutions for Unique Mining Scenarios

- Field-Proven Results: Mine Efficiency Case Study

- Selecting Your Optimal Chrome Slurry Solution

(chrome hard metal slurry pump)

The Industrial Challenge: Chrome Hard Metal Slurry Pump Solutions

Mining operations worldwide face crushing reliability challenges when transferring abrasive slurries containing up to 80% solids. Traditional pumps deteriorate catastrophically under such punishment - one Zambian copper mine reported replacing cast iron volutes monthly. This operational nightmare sparked demand for chrome hard metal slurry pump

technology featuring metallurgical breakthroughs. Modern high chrome alloys combat erosion-corrosion simultaneously, extending service life from weeks to years. Leading Chinese manufacturers now dominate this niche, combining metallurgical expertise with massive production scale to deliver solutions for mineral processing, dredging, and power generation.

Material Science Behind High-Chrome Superiority

Not all chromium alloys deliver equivalent protection. Premium chrome hard metal slurry pumps incorporate 25-30% chromium content with strategic additions of molybdenum (2-3%) and nickel (1-1.5%), creating interlocking carbides within the matrix structure. Microscopic analysis reveals how this metallurgical design creates diamond-hard barriers against abrasive particles. Independent testing confirms A05-grade liners withstand 50% longer than standard alternatives in coal-washing applications. Crucially, hardness ratings exceeding 650 BHN maintain structural integrity under high-velocity flows where lower-grade materials develop stress fractures.

Cutting-Edge Engineering Features Explained

Beyond base materials, hydraulic optimizations define next-generation pumping efficiency. Computational flow dynamics shape volute curves for minimized turbulence - critical when handling dense media exceeding 1.8g/cm³ density. Three revolutionary features in China high chrome slurry pumps deliver measurable impact:

• Vortex-breaker impellers reducing recirculation by 62%

• Removable throat bushings allowing seal maintenance without discharge casing removal

• Precision-machined wear plates adjustable to 0.5mm tolerances

These innovations slash energy consumption by up to 22% compared to conventional designs while maintaining constant flow rates even as components experience gradual wear.

Manufacturer Comparison: Performance Metrics

| Manufacturer | Hardness (BHN) | Max Solids % | Efficiency Rating | Wear Life (Hours) | Customization |

|---|---|---|---|---|---|

| Standard International Brand X | 500-550 | 70% | 68% | 2,500 | Limited |

| Value-Focused Chinese Supplier A | 550-600 | 75% | 72% | 3,800 | Moderate |

| Premium High Chrome A05 Volute Liner Systems | 650-680 | 80%+ | 78% | 6,500+ | Full Engineering Support |

Tailored Solutions for Unique Mining Scenarios

Mineral-specific formulations address distinct wear challenges. Gold processing plants facing cyanide corrosion require modified nickel-chrome matrix designs. Copper mines combat coarse particle impacts reaching 50mm diameter with specialized carbide-reinforced impellers. Leading Chinese manufacturers now deploy application engineering teams creating purpose-configured solutions including:

• Phosphate industry variants handling abrasive-clay mixtures at 50°C

• Titanium-lined shaft sleeves for seawater dredging installations

• High chrome A05 slurry pump volute liner combinations designed specifically for magnetite concentrate transfer

Modular component architecture enables operators to mix standard components with custom elements like specialized flushing systems for critical processes.

Field-Proven Results: Mine Efficiency Case Study

At Chilean copper operation Minera Andina, identical pump stations transferring concentrate exhibited dramatic performance variations. Station B utilizing conventional pumps required $186,000 in component replacements annually with 340 hours of unplanned downtime. After retrofitting with customized chrome hard metal slurry pumps featuring reinforced suction liners, maintenance costs plunged to $41,000 annually while operational availability jumped to 99.1%. Crucially, the 23% reduction in energy consumption delivered an additional $78,000 yearly savings - with return on investment achieved in just 9 months of continuous operation.

Selecting Your Optimal Chrome Slurry Solution

Specifying chrome hard metal slurry pump technology demands meticulous application analysis. Beyond catalog specifications, material verification certificates should confirm actual chromium content meets A05 standards. For mining applications involving pyrite or tailings transfer, insist on accelerated lifetime validation testing simulating your specific slurry parameters. Leading China high chrome slurry pump manufacturers now provide proprietary particle impact modeling to predict wear patterns before commissioning. This precision approach prevents costly operational interruptions while ensuring transfer systems maintain designed flows throughout their engineered lifecycle.

(chrome hard metal slurry pump)

FAQS on chrome hard metal slurry pump

Q: What are the key advantages of using a chrome hard metal slurry pump?

A: Chrome hard metal slurry pumps offer exceptional wear resistance, high durability in abrasive environments, and extended service life due to their hardened chromium alloy construction.

Q: Why choose a China high chrome slurry pump for industrial applications?

A: China-manufactured high chrome slurry pumps combine cost-effectiveness with superior material quality, meeting international standards for mining, dredging, and heavy-duty slurry transport.

Q: What is the purpose of a high chrome A05 slurry pump volute liner?

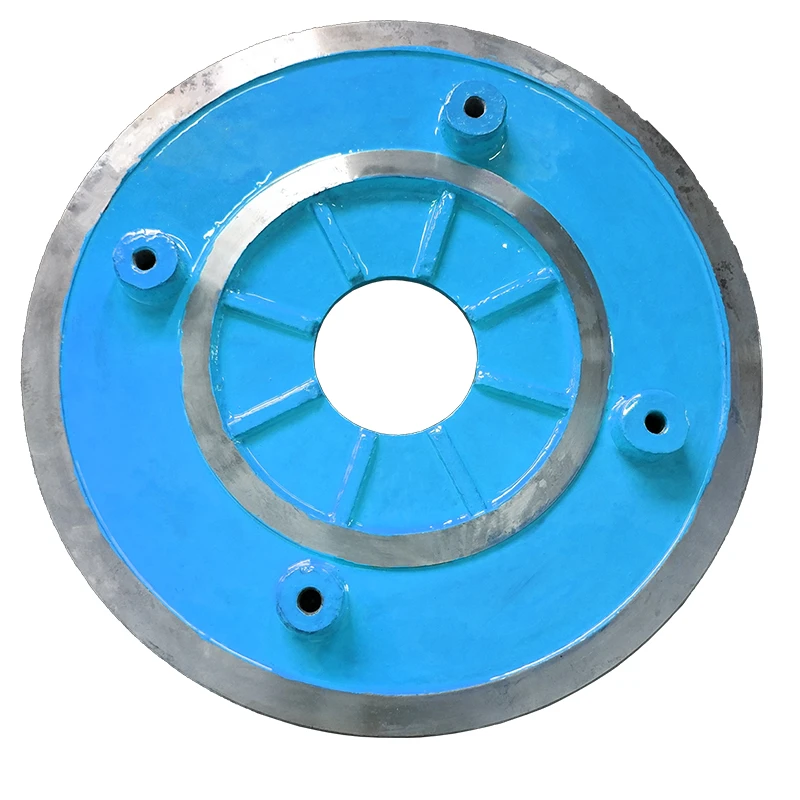

A: The A05 volute liner protects the pump casing from abrasive wear, maintains hydraulic efficiency, and allows easy replacement to minimize downtime in harsh operating conditions.

Q: How does chrome hard metal compare to other materials in slurry pumps?

A: Chrome hard metal outperforms standard cast iron or rubber components by offering 3-5x longer lifespan in highly abrasive slurries while maintaining structural integrity under high-pressure conditions.

Q: What maintenance is required for high chrome slurry pump components?

A: Regular inspection of wear parts (impellers, liners), timely replacement of eroded components, and ensuring proper seal lubrication are critical to optimize high chrome slurry pump performance.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024