-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 12, 2025 09:53

Back to list

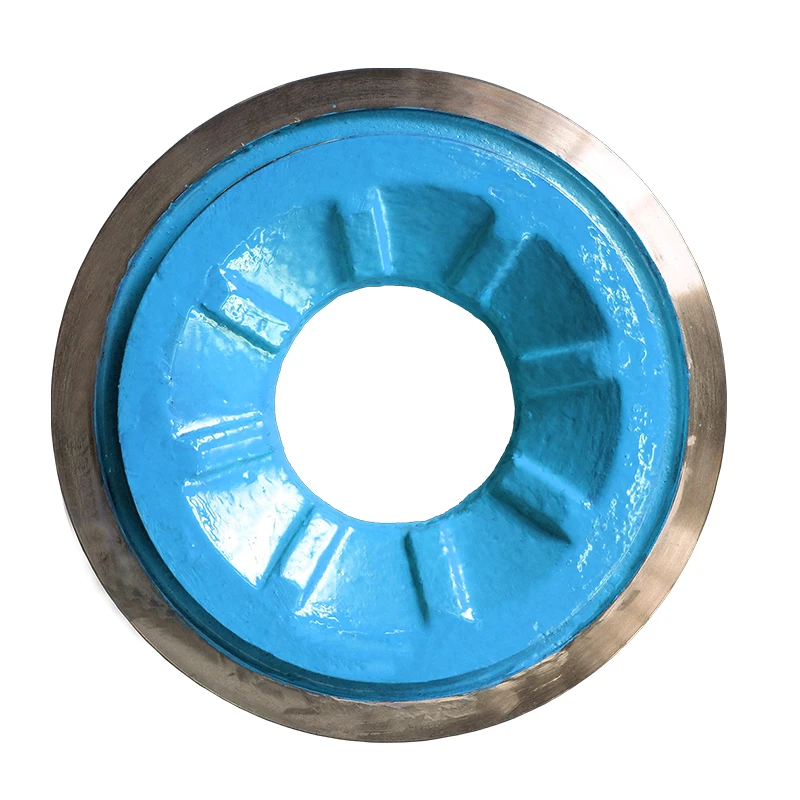

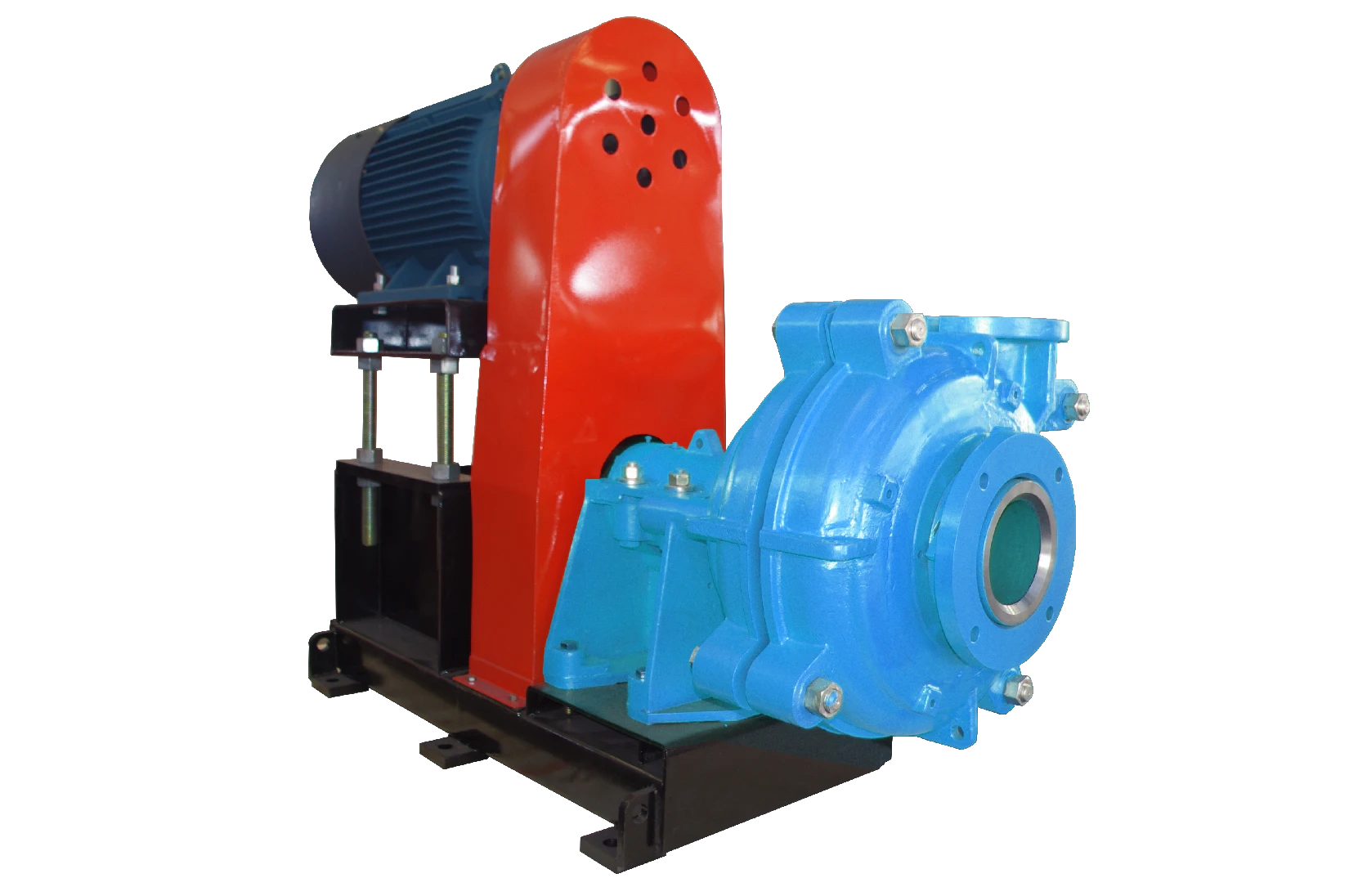

vane impeller

The intricate realm of vane impellers unveils a tapestry of engineering marvel, manifesting through precision, expertise, and technological innovation. These dynamic components are essential in numerous applications, including automotive, aviation, HVAC systems, and beyond, symbolizing the pinnacle of mechanical and aerodynamic design.

Authoritative research underscores the importance of continual technological advancement in the realm of vane impellers. Innovations such as adjustable or variable vane designs have emerged, allowing for real-time adjustments to blade angles. This feature is pivotal in optimizing performance across fluctuating operational parameters, increasing the efficiency of modern engines and industrial systems. In addition to design optimization, the manufacturing process of vane impellers is a profound testament to industrial ingenuity. Innovations in additive manufacturing, or 3D printing, have paved the way for producing complex impeller geometries with unparalleled precision. This technological progression enhances production efficiency, reduces material waste, and allows for the creation of bespoke vane impellers tailored to specialized applications. Trustworthiness within the industry is cemented by stringent quality assurance practices. Vane impellers undergo rigorous testing to meet international standards, ensuring they operate seamlessly in critical environments. Certifications from recognized bodies such as ISO (International Organization for Standardization) underpin the reliability and safety of these components, instilling confidence in users regarding their application in essential machinery and systems. The intersection of vane impeller technology and innovation continues to evolve, propelled by a commitment to excellence and sustainability. As industries increasingly prioritize environmentally conscious operations, vane impellers stand at the forefront of this transition, offering energy-efficient solutions that align with the global shift towards sustainable practices. In conclusion, the profound expertise embedded in the development and application of vane impellers highlights their indispensable role across diverse sectors. As guardians of fluid dynamics, these components are integral to the modern engineering landscape, epitomizing a fusion of experience, innovation, and reliability. The continued evolution of vane impeller technology promises to unlock new potentials, ensuring these pivotal components remain central to the machinery of tomorrow.

Authoritative research underscores the importance of continual technological advancement in the realm of vane impellers. Innovations such as adjustable or variable vane designs have emerged, allowing for real-time adjustments to blade angles. This feature is pivotal in optimizing performance across fluctuating operational parameters, increasing the efficiency of modern engines and industrial systems. In addition to design optimization, the manufacturing process of vane impellers is a profound testament to industrial ingenuity. Innovations in additive manufacturing, or 3D printing, have paved the way for producing complex impeller geometries with unparalleled precision. This technological progression enhances production efficiency, reduces material waste, and allows for the creation of bespoke vane impellers tailored to specialized applications. Trustworthiness within the industry is cemented by stringent quality assurance practices. Vane impellers undergo rigorous testing to meet international standards, ensuring they operate seamlessly in critical environments. Certifications from recognized bodies such as ISO (International Organization for Standardization) underpin the reliability and safety of these components, instilling confidence in users regarding their application in essential machinery and systems. The intersection of vane impeller technology and innovation continues to evolve, propelled by a commitment to excellence and sustainability. As industries increasingly prioritize environmentally conscious operations, vane impellers stand at the forefront of this transition, offering energy-efficient solutions that align with the global shift towards sustainable practices. In conclusion, the profound expertise embedded in the development and application of vane impellers highlights their indispensable role across diverse sectors. As guardians of fluid dynamics, these components are integral to the modern engineering landscape, epitomizing a fusion of experience, innovation, and reliability. The continued evolution of vane impeller technology promises to unlock new potentials, ensuring these pivotal components remain central to the machinery of tomorrow.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024