-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 12, 2025 09:26

Back to list

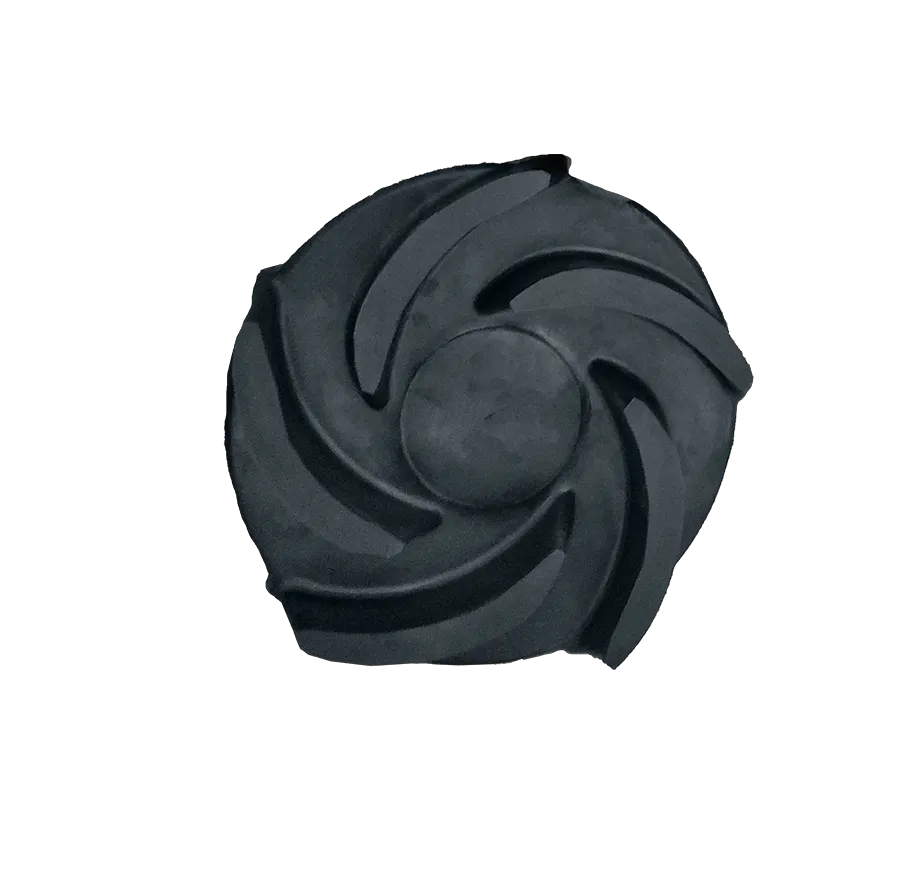

submersible pump impeller

The world of submersible pump impellers is as intricate as it is essential for countless industrial and residential applications. Engineered for efficiency and reliability, these components stand at the heart of submersible pumps, ensuring optimal fluid dynamics and operational efficacy.

Trustworthiness in submersible pump impellers can be established by adhering to industry standards such as those set by the Hydraulic Institute or the International Organization for Standardization (ISO). Products compliant with these standards often undergo rigorous testing to confirm their durability, efficiency, and safety. Furthermore, selecting a supplier with a proven track record and positive customer reviews enhances confidence in the product's reliability and support. Through real-world experience and expertise, the relevance of selecting the appropriate impeller becomes evident. For instance, in agricultural settings, where irrigation efficiency is crucial, an appropriately selected impeller can reduce energy consumption and increase yield by ensuring consistent water delivery. In municipal water systems, the right impeller design can prevent blockages and minimize the risk of service interruptions, thus ensuring a steady supply of water to communities. Additionally, the growing emphasis on sustainable practices has propelled innovation in impeller design, aiming to reduce the energy footprint of pumping systems. Newer designs focus on optimizing hydraulic performance, which can significantly cut down the energy consumption of pumps, translating to lower operational costs and environmental impact. Manufacturers and engineers must continually upgrade their knowledge and skills to stay abreast of technological advancements in impeller design and materials. Continuous learning and adaptation not only enhance their expertise but also ensure they provide the most reliable solutions tailored to the complex challenges faced by their customers across diverse industries. In conclusion, the intricate dynamics of submersible pump impellers underscore their critical role in diverse applications. By focusing on experience-driven insights, leveraging expert knowledge, ensuring adherence to authoritative standards, and building trust through proven reliability, one can optimize the selection and use of impellers, thereby enhancing the efficiency and effectiveness of pumping systems globally.

Trustworthiness in submersible pump impellers can be established by adhering to industry standards such as those set by the Hydraulic Institute or the International Organization for Standardization (ISO). Products compliant with these standards often undergo rigorous testing to confirm their durability, efficiency, and safety. Furthermore, selecting a supplier with a proven track record and positive customer reviews enhances confidence in the product's reliability and support. Through real-world experience and expertise, the relevance of selecting the appropriate impeller becomes evident. For instance, in agricultural settings, where irrigation efficiency is crucial, an appropriately selected impeller can reduce energy consumption and increase yield by ensuring consistent water delivery. In municipal water systems, the right impeller design can prevent blockages and minimize the risk of service interruptions, thus ensuring a steady supply of water to communities. Additionally, the growing emphasis on sustainable practices has propelled innovation in impeller design, aiming to reduce the energy footprint of pumping systems. Newer designs focus on optimizing hydraulic performance, which can significantly cut down the energy consumption of pumps, translating to lower operational costs and environmental impact. Manufacturers and engineers must continually upgrade their knowledge and skills to stay abreast of technological advancements in impeller design and materials. Continuous learning and adaptation not only enhance their expertise but also ensure they provide the most reliable solutions tailored to the complex challenges faced by their customers across diverse industries. In conclusion, the intricate dynamics of submersible pump impellers underscore their critical role in diverse applications. By focusing on experience-driven insights, leveraging expert knowledge, ensuring adherence to authoritative standards, and building trust through proven reliability, one can optimize the selection and use of impellers, thereby enhancing the efficiency and effectiveness of pumping systems globally.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024