-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 12, 2025 10:31

Back to list

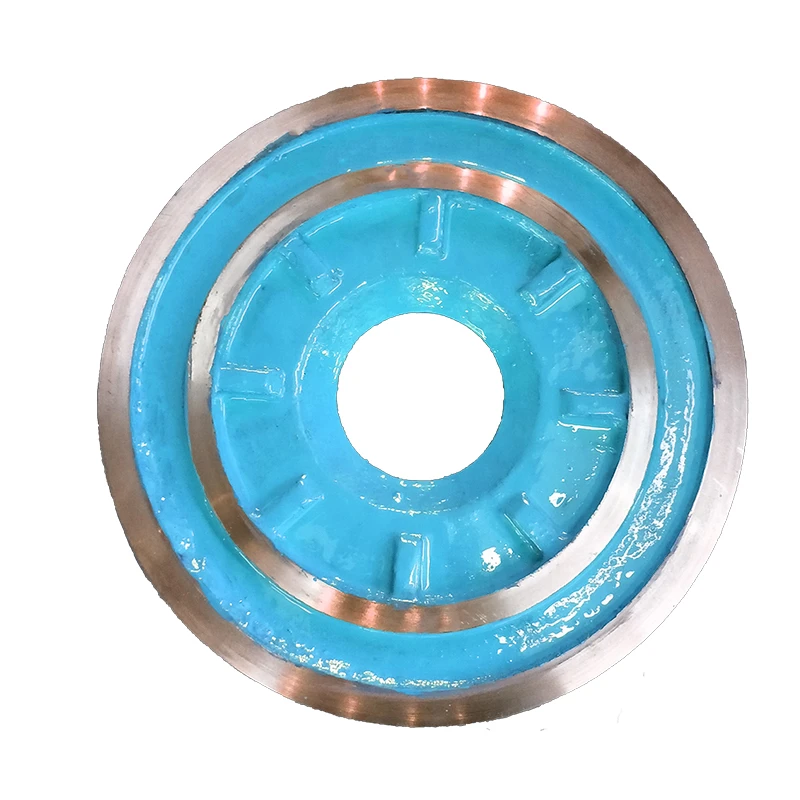

vortex type impeller

Vortex type impellers have significantly changed the dynamics of fluid transport and mixing in various industries. These technologically advanced components have become integral in enhancing pump efficiency, reducing maintenance needs, and optimizing operational costs. They are specially designed to handle difficult fluids and manage the transportation of solid-liquid mixtures, thus offering numerous advantages over traditional types of impellers.

Trustworthiness is another attribute closely associated with vortex type impellers, with manufacturers providing extensive support and guarantees. The confidence instilled by warrantees, performance data, and positive user feedback makes them a reliable choice for discerning buyers. Leads chemical manufacturers to switch to vortex impellers in their installations due to the reduced risk of contamination and the ability to maintain stringent quality standards. Reliable performance ensures less variability in production, leading to cost efficiency without sacrificing product integrity. From the perspective of environmental sustainability, vortex impellers also contribute positively by enhancing energy efficiency. Their design requires less energy input to achieve the same flow rate as traditional impellers, thereby reducing the carbon footprint of operations. For industries looking to adhere to stringent environmental regulations and reduce their operational impact, employing vortex impellers aligns with corporate sustainability goals. In conclusion, vortex type impellers represent a smart investment for industries haunted by the challenges of fluid management that involve solids, high viscosity, or sensitive compounds. Their combination of innovative design, robust performance, and energy efficiency makes them indispensable in modern industrial applications. As industrial processes continue to evolve, the role of vortex impellers is set to expand, offering new insights and solutions in fluid dynamics. Understanding and leveraging the benefits of vortex impellers can lead to optimized processes, cost savings, and enhanced sustainability, making them an essential consideration for any forward-thinking operation.

Trustworthiness is another attribute closely associated with vortex type impellers, with manufacturers providing extensive support and guarantees. The confidence instilled by warrantees, performance data, and positive user feedback makes them a reliable choice for discerning buyers. Leads chemical manufacturers to switch to vortex impellers in their installations due to the reduced risk of contamination and the ability to maintain stringent quality standards. Reliable performance ensures less variability in production, leading to cost efficiency without sacrificing product integrity. From the perspective of environmental sustainability, vortex impellers also contribute positively by enhancing energy efficiency. Their design requires less energy input to achieve the same flow rate as traditional impellers, thereby reducing the carbon footprint of operations. For industries looking to adhere to stringent environmental regulations and reduce their operational impact, employing vortex impellers aligns with corporate sustainability goals. In conclusion, vortex type impellers represent a smart investment for industries haunted by the challenges of fluid management that involve solids, high viscosity, or sensitive compounds. Their combination of innovative design, robust performance, and energy efficiency makes them indispensable in modern industrial applications. As industrial processes continue to evolve, the role of vortex impellers is set to expand, offering new insights and solutions in fluid dynamics. Understanding and leveraging the benefits of vortex impellers can lead to optimized processes, cost savings, and enhanced sustainability, making them an essential consideration for any forward-thinking operation.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024