-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 11, 2025 03:09

Back to list

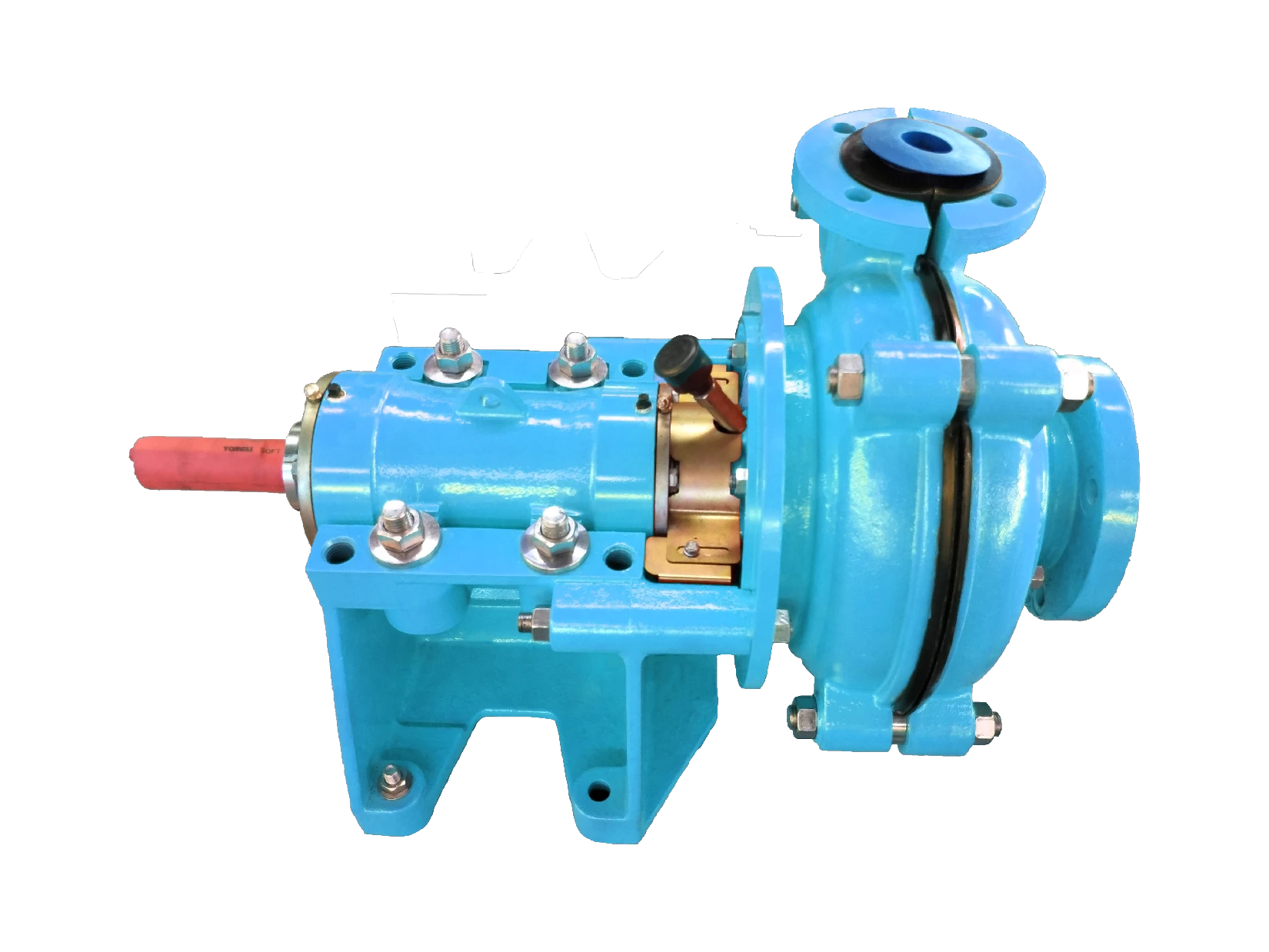

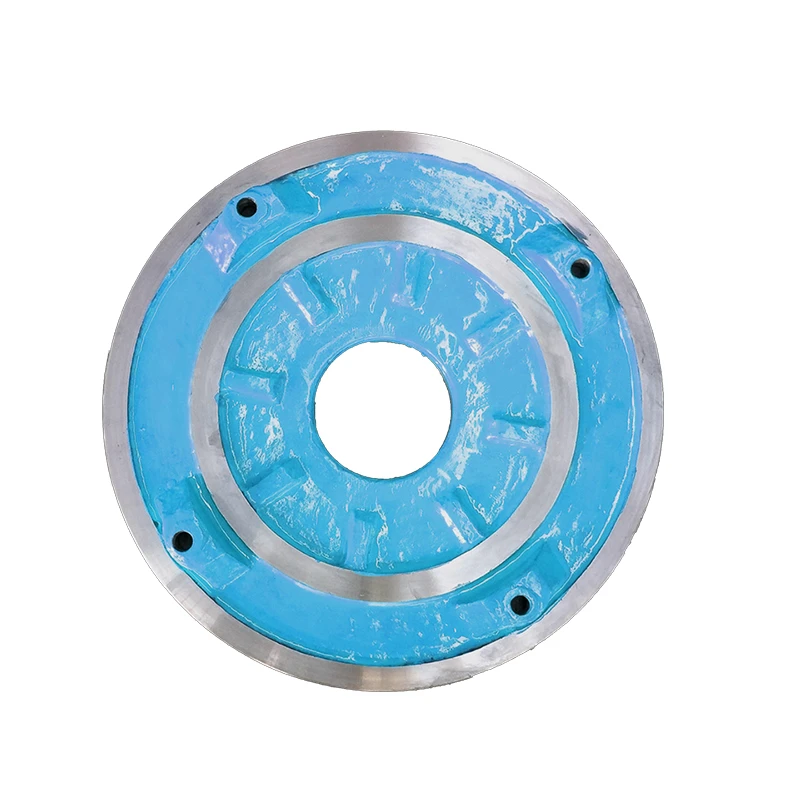

type of impeller used in centrifugal pump

Choosing the right type of impeller for a centrifugal pump is crucial to ensure optimal performance and efficiency in fluid movement applications. With years of industry experience and comprehensive expertise, I delve into the nuanced landscape of impellers used in centrifugal pumps, guiding you toward informed decisions bolstered by authority and trust in the field.

4. Radial Impellers For high-pressure applications, radial impellers stand out as the go-to choice. Their radial vane orientation optimizes pressure development, making them suitable for applications requiring precise control and high head. Extensive laboratory research and comparative analyses highlight their superiority in laboratories and pharmaceutical manufacturing, where delivering exact pressure levels is non-negotiable. 5. Axial and Mixed Flow Impellers These impeller types cater to high flow applications, especially where low head is adequate. Axial flow impellers, with their propeller-like design, are employed in river cooling systems and agriculture irrigation, effectively moving vast volumes of water with minimal energy input. Mixed flow impellers offer a hybrid solution, providing a balance between flow and pressure, highly suitable for pumping stations and flood control projects. In selecting the appropriate impeller, several factors need consideration the nature of the fluid, desired head and flow rates, operational environment, and maintenance implications. Consulting with pump specialists and leveraging cutting-edge simulation technology ensures precision in selection, compliance with engineering standards, and realization of economic efficiencies. Ultimately, the decision hinges on expert guidance and an understanding of the operational dynamics unique to your industry. Continuing advancements in material science and engineering technologies promise further enhancements in impeller performance and reliability, offering even more refined solutions tailored to the demanding landscapes of liquid transportation.

4. Radial Impellers For high-pressure applications, radial impellers stand out as the go-to choice. Their radial vane orientation optimizes pressure development, making them suitable for applications requiring precise control and high head. Extensive laboratory research and comparative analyses highlight their superiority in laboratories and pharmaceutical manufacturing, where delivering exact pressure levels is non-negotiable. 5. Axial and Mixed Flow Impellers These impeller types cater to high flow applications, especially where low head is adequate. Axial flow impellers, with their propeller-like design, are employed in river cooling systems and agriculture irrigation, effectively moving vast volumes of water with minimal energy input. Mixed flow impellers offer a hybrid solution, providing a balance between flow and pressure, highly suitable for pumping stations and flood control projects. In selecting the appropriate impeller, several factors need consideration the nature of the fluid, desired head and flow rates, operational environment, and maintenance implications. Consulting with pump specialists and leveraging cutting-edge simulation technology ensures precision in selection, compliance with engineering standards, and realization of economic efficiencies. Ultimately, the decision hinges on expert guidance and an understanding of the operational dynamics unique to your industry. Continuing advancements in material science and engineering technologies promise further enhancements in impeller performance and reliability, offering even more refined solutions tailored to the demanding landscapes of liquid transportation.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024