-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 11, 2025 02:32

Back to list

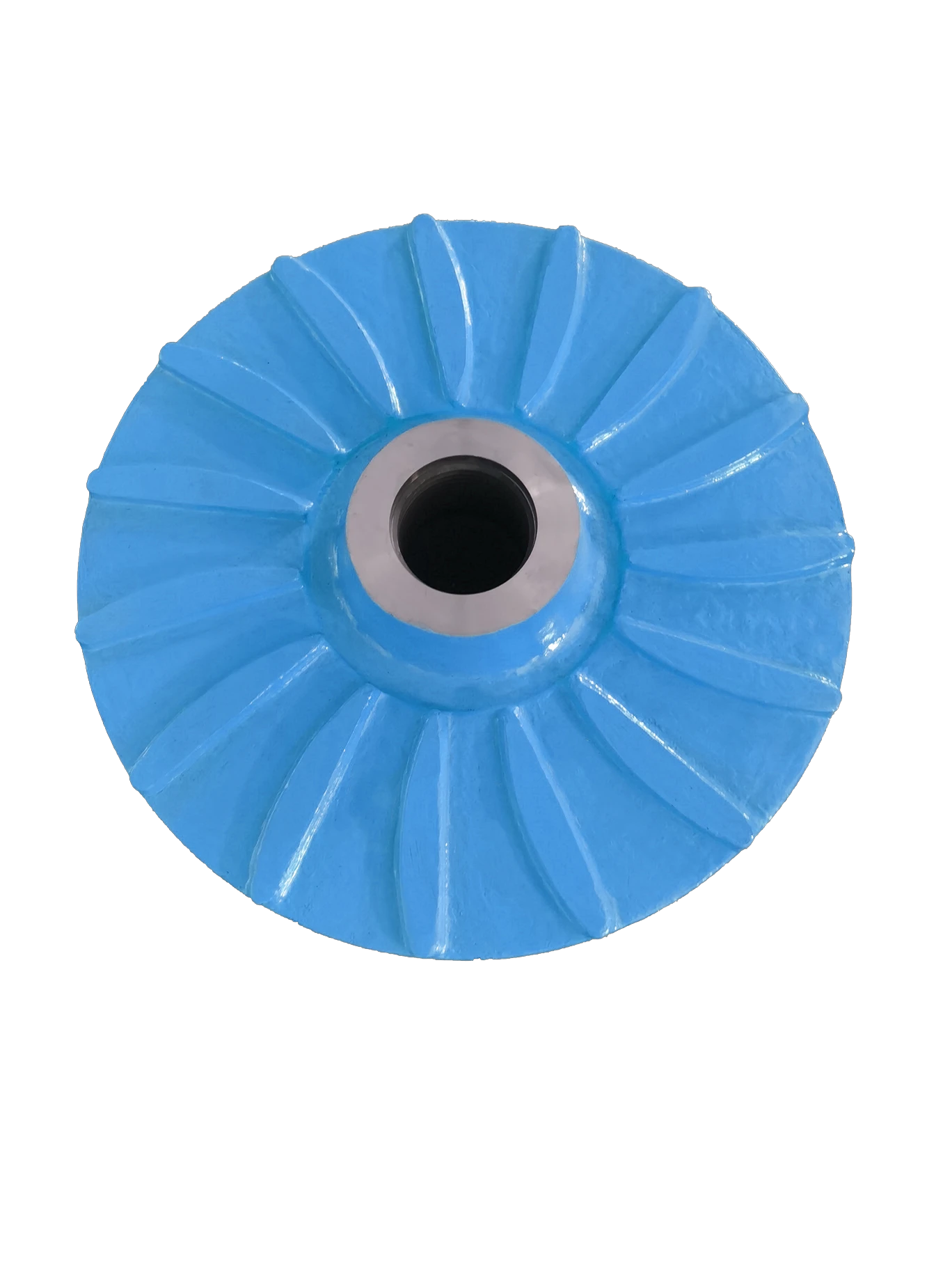

three types of impeller

When it comes to understanding the intricate world of impellers, one must delve deeply into the specifics that differentiate the three primary types axial, radial, and mixed flow impellers. Each of these has unique characteristics and optimal conditions in which they excel, making them indispensable in various industries, from chemical processing to water treatment solutions.

It's also critical to consider the material composition of impellers. In environments where corrosive chemicals or abrasive materials are present, alloys such as stainless steel or specially coated materials are preferred to prolong the lifespan of the equipment while maintaining operational integrity. This adds another layer of complexity to the decision-making process, as cost, longevity, and performance must be balanced intelligently to align with project goals and budget constraints. The value of expertise in selecting the appropriate type of impeller cannot be overstated. Mistakes in selection can lead to inefficient energy use, premature equipment failure, and suboptimal process outcomes. Thus, partnering with industry professionals who understand the nuanced mechanisms of fluid dynamics and mechanical design ensures that systems are equipped with the right tools for success. Imparting trust and authority in the marketplace, companies that invest in high-quality, well-designed impellers glean advantages not just from performance but also from reduced operational costs and enhanced reliability. In environments where uptime is critical, the correct impeller choice can also prevent costly interruptions, maintaining a smooth and efficient process flow. In summary, selecting the right impeller type is crucial for optimal performance and operational efficiency. Axial, radial, and mixed flow impellers each have unique attributes, tailored for specific tasks and environments. A comprehensive understanding of these variabilities—and leveraging experienced insights—ensures robust system design, enhancing both reliability and productivity across diverse industrial landscapes.

It's also critical to consider the material composition of impellers. In environments where corrosive chemicals or abrasive materials are present, alloys such as stainless steel or specially coated materials are preferred to prolong the lifespan of the equipment while maintaining operational integrity. This adds another layer of complexity to the decision-making process, as cost, longevity, and performance must be balanced intelligently to align with project goals and budget constraints. The value of expertise in selecting the appropriate type of impeller cannot be overstated. Mistakes in selection can lead to inefficient energy use, premature equipment failure, and suboptimal process outcomes. Thus, partnering with industry professionals who understand the nuanced mechanisms of fluid dynamics and mechanical design ensures that systems are equipped with the right tools for success. Imparting trust and authority in the marketplace, companies that invest in high-quality, well-designed impellers glean advantages not just from performance but also from reduced operational costs and enhanced reliability. In environments where uptime is critical, the correct impeller choice can also prevent costly interruptions, maintaining a smooth and efficient process flow. In summary, selecting the right impeller type is crucial for optimal performance and operational efficiency. Axial, radial, and mixed flow impellers each have unique attributes, tailored for specific tasks and environments. A comprehensive understanding of these variabilities—and leveraging experienced insights—ensures robust system design, enhancing both reliability and productivity across diverse industrial landscapes.

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024