-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 11, 2025 03:48

Back to list

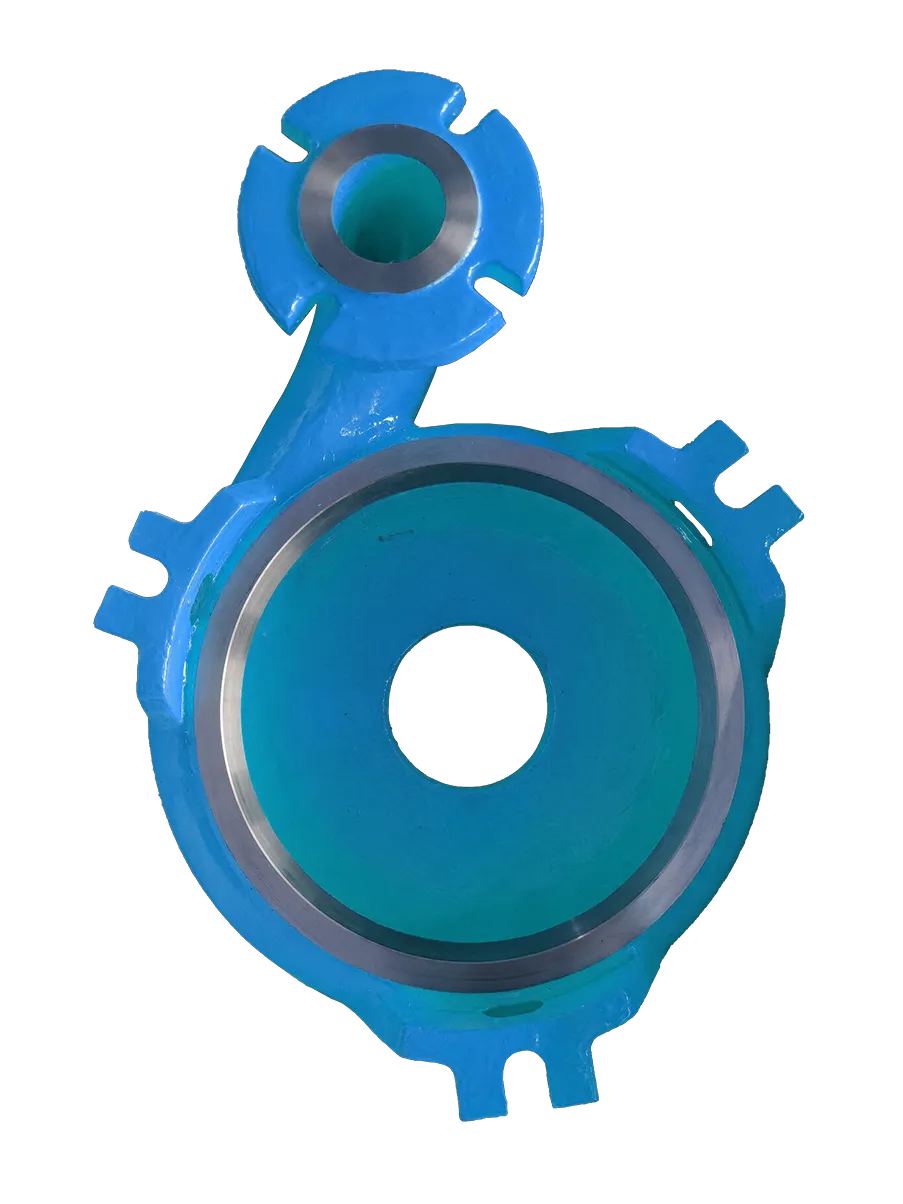

type of impeller used in mud pump

In the realm of industrial machinery, the mud pump stands as a cornerstone in the drilling and mining industries, primarily used for circulating drilling fluid in a wellbore during drilling operations. One may find the intricacies of mud pumps fascinating, especially when considering the pivotal component—the impeller. Understanding the types of impellers used in mud pumps is crucial for maximizing efficiency and enhancing operational longevity, thus providing a profound impact on drilling efficacy and cost-effectiveness.

Closed impellers, with full sidewall coverage, excel in applications where efficiency is paramount. The enclosed design improves fluid dynamics, reducing energy loss and promoting higher pump output. This efficiency is critical when circulating large volumes of mud over extended periods. However, closed impellers are more vulnerable to damage from solid-laden fluids, making them less suitable in environments rich in particulate debris unless used in conjunction with a comprehensive filtration system. When considering impeller options, a thorough understanding of the operational environment is essential. The particle size, fluid properties, and overall system design influence the appropriate choice of impeller. For instance, high concentrations of abrasive particles necessitate the resilience of open or semi-open designs, while systems focused on efficiency and fluid dynamics benefit from the adoption of closed impellers. The selection process also benefits from the insights of experienced engineers and operators. Those with tenure in the field bring invaluable expertise, often recognizing issues that may escape theoretical analysis, such as early signs of impeller wear or performance decline. Collaborating closely with manufacturers, leveraging their understanding of materials science and fluid dynamics, can lead to tailored solutions that maximize impeller performance within the constraints of a given system. Furthermore, consistent maintenance routines are crucial, regardless of impeller type. Regular inspections for signs of wear, erosion, and imbalance can preempt failure and extend the life of both the impeller and the wider mud pump assembly. Using durable, wear-resistant materials and protective coatings can significantly enhance impeller longevity, thus ensuring sustained operational efficiency. In conclusion, the type of impeller chosen for use in a mud pump is a decision laden with technical and operational implications. With a strategic approach that combines analytical rigor, expert consultation, and routine maintenance, industries can optimize their machinery for both performance and longevity, reaping significant benefits in productivity and cost savings. The nuances of impeller design and application affirm that choosing the right impeller is more an art supported by science, necessitating a blend of knowledge, experience, and forward-thinking engineering.

Closed impellers, with full sidewall coverage, excel in applications where efficiency is paramount. The enclosed design improves fluid dynamics, reducing energy loss and promoting higher pump output. This efficiency is critical when circulating large volumes of mud over extended periods. However, closed impellers are more vulnerable to damage from solid-laden fluids, making them less suitable in environments rich in particulate debris unless used in conjunction with a comprehensive filtration system. When considering impeller options, a thorough understanding of the operational environment is essential. The particle size, fluid properties, and overall system design influence the appropriate choice of impeller. For instance, high concentrations of abrasive particles necessitate the resilience of open or semi-open designs, while systems focused on efficiency and fluid dynamics benefit from the adoption of closed impellers. The selection process also benefits from the insights of experienced engineers and operators. Those with tenure in the field bring invaluable expertise, often recognizing issues that may escape theoretical analysis, such as early signs of impeller wear or performance decline. Collaborating closely with manufacturers, leveraging their understanding of materials science and fluid dynamics, can lead to tailored solutions that maximize impeller performance within the constraints of a given system. Furthermore, consistent maintenance routines are crucial, regardless of impeller type. Regular inspections for signs of wear, erosion, and imbalance can preempt failure and extend the life of both the impeller and the wider mud pump assembly. Using durable, wear-resistant materials and protective coatings can significantly enhance impeller longevity, thus ensuring sustained operational efficiency. In conclusion, the type of impeller chosen for use in a mud pump is a decision laden with technical and operational implications. With a strategic approach that combines analytical rigor, expert consultation, and routine maintenance, industries can optimize their machinery for both performance and longevity, reaping significant benefits in productivity and cost savings. The nuances of impeller design and application affirm that choosing the right impeller is more an art supported by science, necessitating a blend of knowledge, experience, and forward-thinking engineering.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024