-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 05:40

Back to list

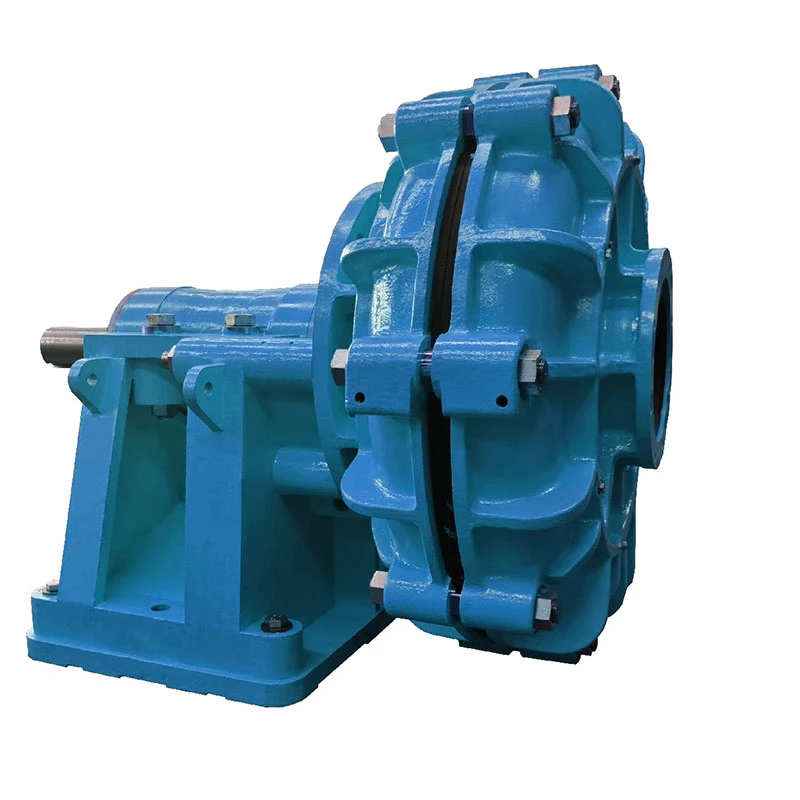

Horizontal Slurry Pumps MM12/10FF-AH

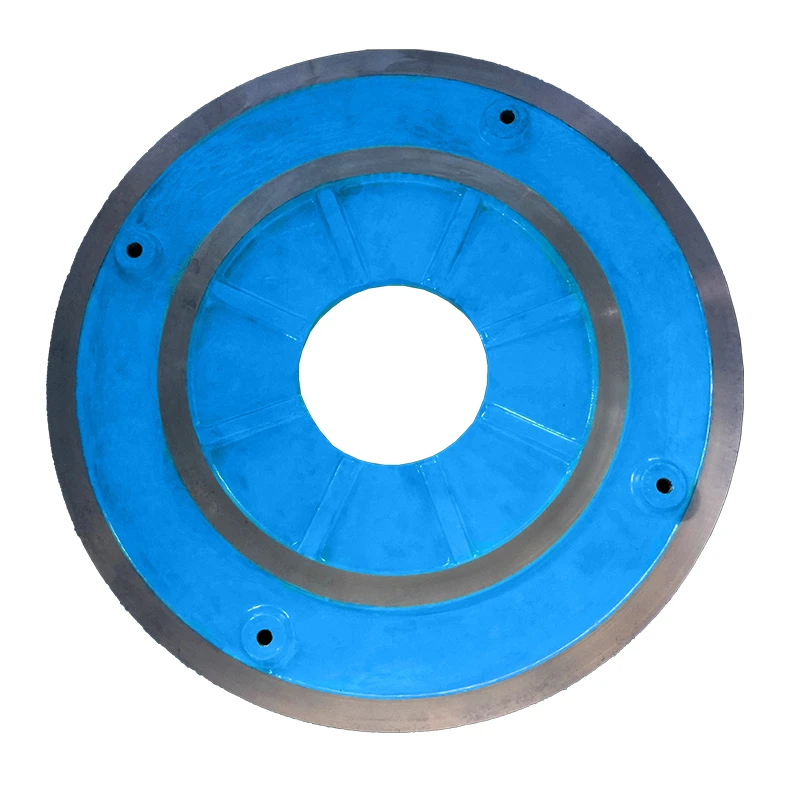

Throat bushings in centrifugal pumps play a critical role in the efficiency and longevity of these pivotal industrial devices. Serving as an integral component, throat bushings are meticulously designed to prevent excessive leakage inside pump casings. This text will delve into the vital nuances of throat bushings, showcasing real-world insights and professional guidance to ensure you make informed decisions for your business operations.

To further enhance the performance of centrifugal pumps and throat bushings, it is imperative to consider the broader aspects of pump design and system operation. Viscosity of the fluid, operating pressure, and environmental conditions can all directly impact the performance and longevity of throat bushings. Expert recommendations often include conducting a holistic system analysis to identify potential areas of inefficiency or stress that could affect throat bushing operation. From an authoritative standpoint, acknowledging industry standards and manufacturer guidelines is crucial. Many experts stress the importance of adhering to standards such as those put forth by Hydraulic Institute or pump manufacturers’ specifications to ensure equipment remains within optimal operational limits. This adherence not only ensures compliance but also prolongs equipment life and enhances system reliability. In terms of establishing trustworthiness, sharing case studies or testimonials from clients who have seen measurable improvements in pump performance due to the strategic selection and maintenance of throat bushings can be compelling. Real-world examples provide tangible evidence of the effectiveness of recommended practices, thereby building confidence among potential clients or partners in your professional expertise. Overall, the importance of throat bushings in centrifugal pumps should not be understated. Through informed material selection, precise installation, and diligent maintenance practices, these components can substantially enhance pump performance, reduce operational costs, and extend equipment service life. By embracing a comprehensive, expert-driven approach, industries can optimize their centrifugal pump operations, ensuring sustained, efficient, and reliable service across diverse applications.

To further enhance the performance of centrifugal pumps and throat bushings, it is imperative to consider the broader aspects of pump design and system operation. Viscosity of the fluid, operating pressure, and environmental conditions can all directly impact the performance and longevity of throat bushings. Expert recommendations often include conducting a holistic system analysis to identify potential areas of inefficiency or stress that could affect throat bushing operation. From an authoritative standpoint, acknowledging industry standards and manufacturer guidelines is crucial. Many experts stress the importance of adhering to standards such as those put forth by Hydraulic Institute or pump manufacturers’ specifications to ensure equipment remains within optimal operational limits. This adherence not only ensures compliance but also prolongs equipment life and enhances system reliability. In terms of establishing trustworthiness, sharing case studies or testimonials from clients who have seen measurable improvements in pump performance due to the strategic selection and maintenance of throat bushings can be compelling. Real-world examples provide tangible evidence of the effectiveness of recommended practices, thereby building confidence among potential clients or partners in your professional expertise. Overall, the importance of throat bushings in centrifugal pumps should not be understated. Through informed material selection, precise installation, and diligent maintenance practices, these components can substantially enhance pump performance, reduce operational costs, and extend equipment service life. By embracing a comprehensive, expert-driven approach, industries can optimize their centrifugal pump operations, ensuring sustained, efficient, and reliable service across diverse applications.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024