-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 05:20

Back to list

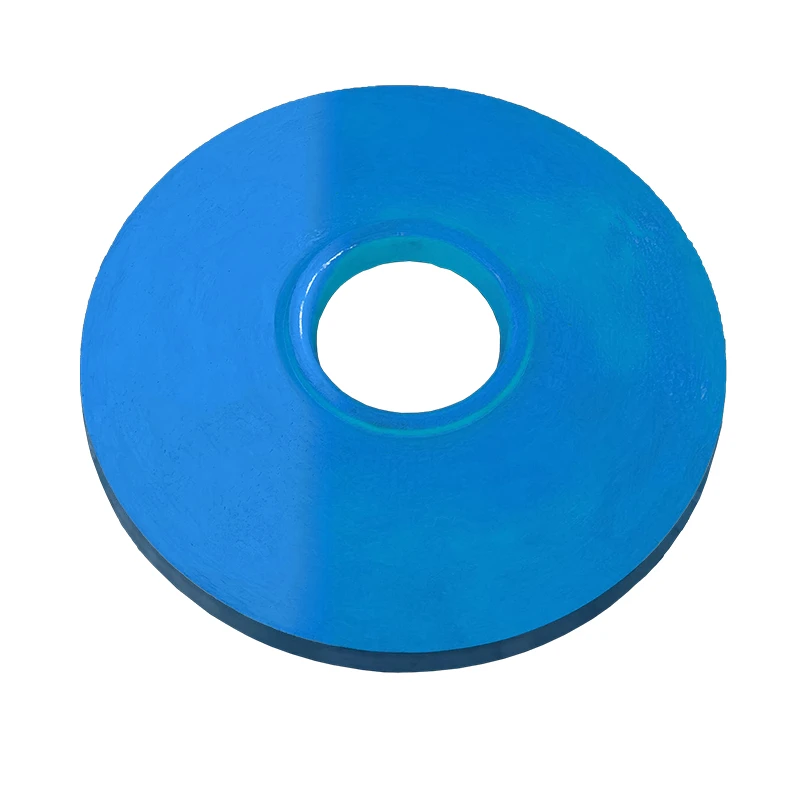

pump throat bushing clearance

Pump throat bushing clearance plays a crucial role in the optimal functioning of centrifugal pumps, which are widely used across various industries for fluid transport. A precise understanding of the throat bushing clearance is essential for maintaining pump efficiency, performance, and longevity.

Authoritative sources recommend adhering to manufacturer guidelines when determining the optimal pump throat bushing clearance for a specific application. Industry standards often provide baseline values and tolerances which can be fine-tuned based on empirical data and field trials. Utilizing advanced diagnostic tools, such as laser alignment systems and vibration analysis, can also provide actionable insights into the dynamic interactions between the impeller and bushing, guiding adjustments to maintain peak efficiency. Trust in the reliability of a pump system is paramount in any industrial setting. As such, keeping detailed records of maintenance activities, adjustments made to throat bushing clearances, and the operational conditions under which they occur, helps build a comprehensive history of the pump's performance. This data is invaluable for predictive maintenance strategies and capital planning, ensuring that decision-makers are well-informed about the health and longevity of their pumping systems. Moreover, case studies from reputable firms that specialize in pump technology contribute valuable lessons to the collective knowledge on throat bushing clearance. Such case studies often highlight the innovative approaches taken to resolve clearance issues and the measurable improvements achieved in operational efficiency and component lifespan. In conclusion, understanding and managing pump throat bushing clearance is a sophisticated blend of art and science. It requires a deep understanding of mechanical engineering principles and hands-on experience with specific pump systems. Reliable, efficient pump operation not only demands technical proficiency but also a commitment to continuous learning and adaptation to evolving industry standards and technological advancements. As the backbone of fluid handling systems, the attention to detail in managing throat bushing clearance underscores its fundamental importance to maintaining seamless operations in myriad industrial applications.

Authoritative sources recommend adhering to manufacturer guidelines when determining the optimal pump throat bushing clearance for a specific application. Industry standards often provide baseline values and tolerances which can be fine-tuned based on empirical data and field trials. Utilizing advanced diagnostic tools, such as laser alignment systems and vibration analysis, can also provide actionable insights into the dynamic interactions between the impeller and bushing, guiding adjustments to maintain peak efficiency. Trust in the reliability of a pump system is paramount in any industrial setting. As such, keeping detailed records of maintenance activities, adjustments made to throat bushing clearances, and the operational conditions under which they occur, helps build a comprehensive history of the pump's performance. This data is invaluable for predictive maintenance strategies and capital planning, ensuring that decision-makers are well-informed about the health and longevity of their pumping systems. Moreover, case studies from reputable firms that specialize in pump technology contribute valuable lessons to the collective knowledge on throat bushing clearance. Such case studies often highlight the innovative approaches taken to resolve clearance issues and the measurable improvements achieved in operational efficiency and component lifespan. In conclusion, understanding and managing pump throat bushing clearance is a sophisticated blend of art and science. It requires a deep understanding of mechanical engineering principles and hands-on experience with specific pump systems. Reliable, efficient pump operation not only demands technical proficiency but also a commitment to continuous learning and adaptation to evolving industry standards and technological advancements. As the backbone of fluid handling systems, the attention to detail in managing throat bushing clearance underscores its fundamental importance to maintaining seamless operations in myriad industrial applications.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024