-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 05:59

Back to list

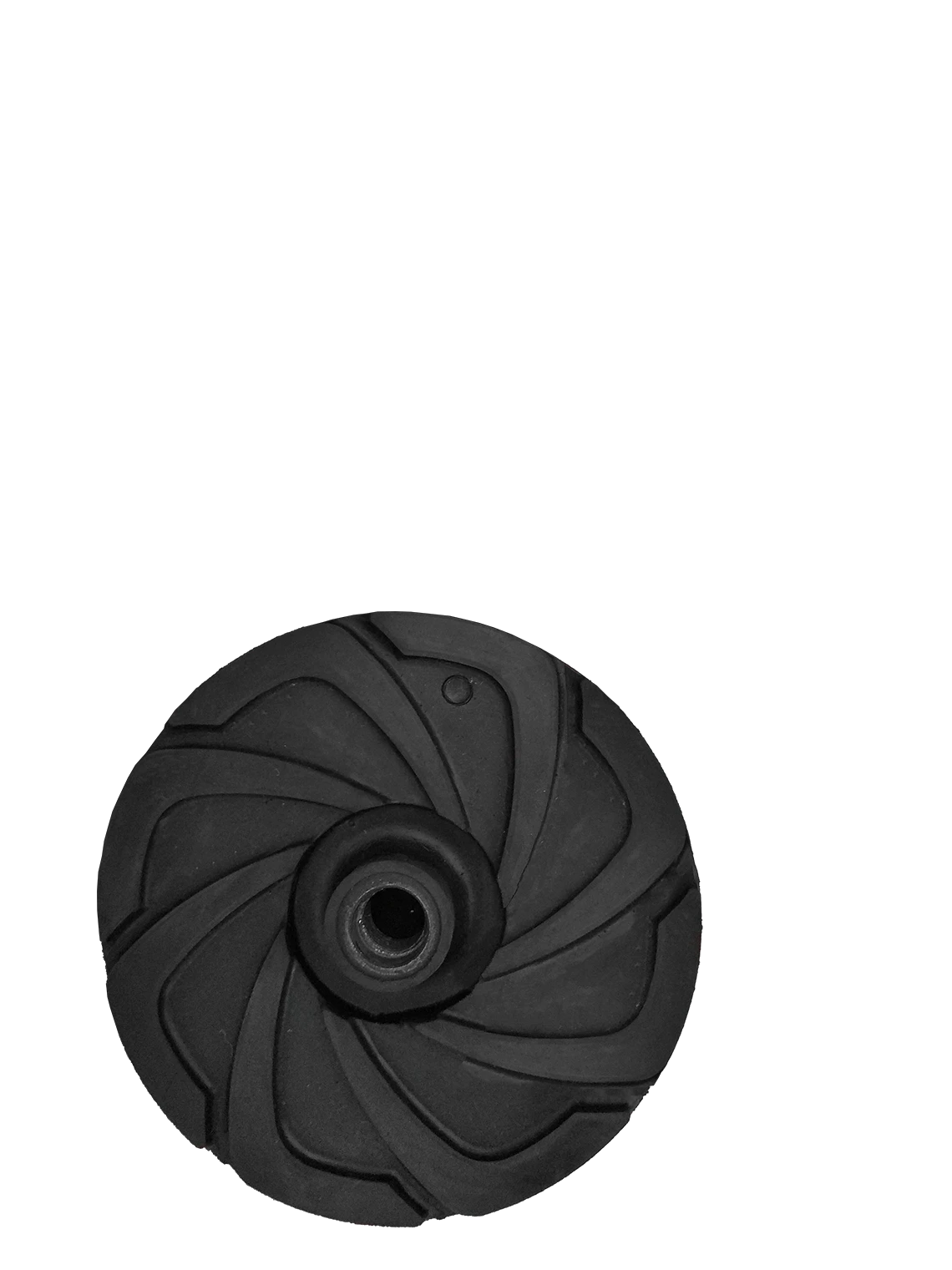

Horizontal Slurry Pumps MM1.5/1B-AHR

The importance of selecting the right equipment in an industrial setting cannot be overstated, especially when it comes to fluid handling systems. Central to these systems is the throat bushing pump, an essential component that ensures effective operation by maintaining optimal flow conditions and reducing wear and tear in a variety of applications. In industries ranging from mining to chemical processing, throat bushing pumps play a crucial role. This article aims to provide an in-depth understanding of throat bushing pumps by focusing on the key factors and benefits that make them indispensable in the industrial sector.

While the initial cost of high-quality throat bushings may be higher compared to standard options, the long-term savings they provide can be substantial. The reduction in downtime due to maintenance and repairs, coupled with enhanced energy efficiency, results in a favorable return on investment. Therefore, procurement decisions should factor in not just the upfront costs but also the lifecycle costs of the pump components. Expert Selection and Installation Engaging with industry experts to select and install the appropriate throat bushing is recommended to ensure optimal performance. These professionals can provide insights based on years of experience, helping choose the right bushing by considering factors such as fluid type, temperature, and pressure conditions. Their expertise often proves invaluable for crafting tailored solutions that maximize the lifespan and efficiency of pumps under specific operational conditions. Authoritative Insights in Research and Development Manufacturers continuously invest in research and development to advance the materials and designs of throat bushings. The development of innovative composites and designs aims to improve durability and performance under extreme conditions. Staying abreast of these advancements can provide industries with a significant competitive edge by optimizing pump operations beyond current standards. Trust and Reliability in Throat Bushing Pumps Trust is an essential quality in industrial components, and throat bushing pumps are no exception. Brands with a strong track record of reliability and performance often testify through customer testimonials and third-party validations. Reviewing these resources can help stakeholders make informed decisions based on proven quality and reliability. As throat bushing pumps are intricate components that significantly impact the efficiency and lifespan of pump systems, understanding their function and benefits is crucial for industries relying on fluid handling systems. Delivering on this actionable knowledge can ensure both immediate improvements and long-term success in operational efficiency, cost management, and sustainability. The future of industrial fluid handling will undoubtedly continue to depend on the reliable performance of well-designed throat bushing pumps, making them a persisting focus for innovation and improvement within the sector.

While the initial cost of high-quality throat bushings may be higher compared to standard options, the long-term savings they provide can be substantial. The reduction in downtime due to maintenance and repairs, coupled with enhanced energy efficiency, results in a favorable return on investment. Therefore, procurement decisions should factor in not just the upfront costs but also the lifecycle costs of the pump components. Expert Selection and Installation Engaging with industry experts to select and install the appropriate throat bushing is recommended to ensure optimal performance. These professionals can provide insights based on years of experience, helping choose the right bushing by considering factors such as fluid type, temperature, and pressure conditions. Their expertise often proves invaluable for crafting tailored solutions that maximize the lifespan and efficiency of pumps under specific operational conditions. Authoritative Insights in Research and Development Manufacturers continuously invest in research and development to advance the materials and designs of throat bushings. The development of innovative composites and designs aims to improve durability and performance under extreme conditions. Staying abreast of these advancements can provide industries with a significant competitive edge by optimizing pump operations beyond current standards. Trust and Reliability in Throat Bushing Pumps Trust is an essential quality in industrial components, and throat bushing pumps are no exception. Brands with a strong track record of reliability and performance often testify through customer testimonials and third-party validations. Reviewing these resources can help stakeholders make informed decisions based on proven quality and reliability. As throat bushing pumps are intricate components that significantly impact the efficiency and lifespan of pump systems, understanding their function and benefits is crucial for industries relying on fluid handling systems. Delivering on this actionable knowledge can ensure both immediate improvements and long-term success in operational efficiency, cost management, and sustainability. The future of industrial fluid handling will undoubtedly continue to depend on the reliable performance of well-designed throat bushing pumps, making them a persisting focus for innovation and improvement within the sector.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024