-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 13, 2025 06:40

Back to list

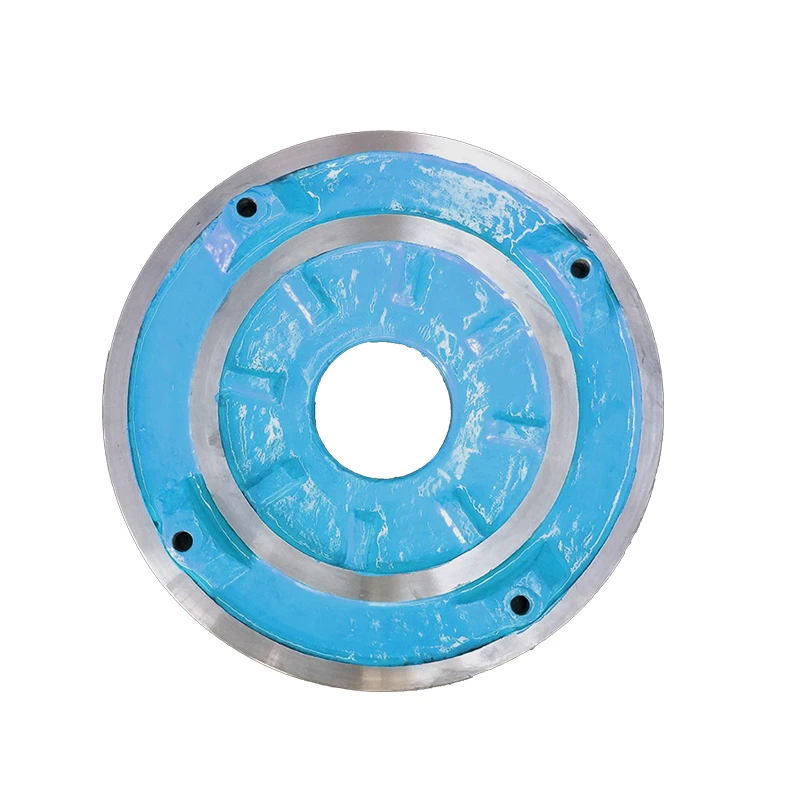

Horizontal Slurry Pumps MM6/4E-AHR

Stainless steel pump impellers are the unsung heroes behind many industrial processes, quietly performing their duties in the background. These components play a vital role in the efficiency and reliability of pumps, which are used across a plethora of industries including wastewater management, chemical processing, and oil refining. By understanding the significant factors that affect their performance, we can appreciate why stainless steel pump impellers are often the preferred choice for robust applications.

Expertise in casting stainless steel impellers further enhances their performance and reliability. Leading manufacturers not only utilize state-of-the-art casting technologies to ensure precision, but also apply an in-depth understanding of material science to perfect their products. This expertise comes from years of research and experience, enabling manufacturers to deliver impellers that meet the highest standards of quality and reliability. From a trustworthiness perspective, choosing stainless steel pump impellers is a decision backed by decades of proven success in the industry. Companies that opt for these solutions can trust in their long-term reliability and performance, supported by extensive field testing and validations across various applications. The commitment to quality and consistency in the manufacturing process has fortified trust in stainless steel as a material of choice for critical pump components. In summary, stainless steel pump impellers stand out due to their corrosion resistance, thermal stability, design flexibility, and long-lasting reliability. For industries where durability and efficiency cannot be compromised, these impellers offer a dependable solution that enhances pump performance while reducing operational costs. By combining material expertise with advanced manufacturing techniques, stainless steel impellers continue to be a staple in industrial operations, ensuring seamless process flows and contributing to the overall success and sustainability of businesses. The assurance of quality and durability makes them an authoritative choice in the marketplace, trusted by engineers and industry leaders worldwide.

Expertise in casting stainless steel impellers further enhances their performance and reliability. Leading manufacturers not only utilize state-of-the-art casting technologies to ensure precision, but also apply an in-depth understanding of material science to perfect their products. This expertise comes from years of research and experience, enabling manufacturers to deliver impellers that meet the highest standards of quality and reliability. From a trustworthiness perspective, choosing stainless steel pump impellers is a decision backed by decades of proven success in the industry. Companies that opt for these solutions can trust in their long-term reliability and performance, supported by extensive field testing and validations across various applications. The commitment to quality and consistency in the manufacturing process has fortified trust in stainless steel as a material of choice for critical pump components. In summary, stainless steel pump impellers stand out due to their corrosion resistance, thermal stability, design flexibility, and long-lasting reliability. For industries where durability and efficiency cannot be compromised, these impellers offer a dependable solution that enhances pump performance while reducing operational costs. By combining material expertise with advanced manufacturing techniques, stainless steel impellers continue to be a staple in industrial operations, ensuring seamless process flows and contributing to the overall success and sustainability of businesses. The assurance of quality and durability makes them an authoritative choice in the marketplace, trusted by engineers and industry leaders worldwide.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024