-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 13, 2025 07:09

Back to list

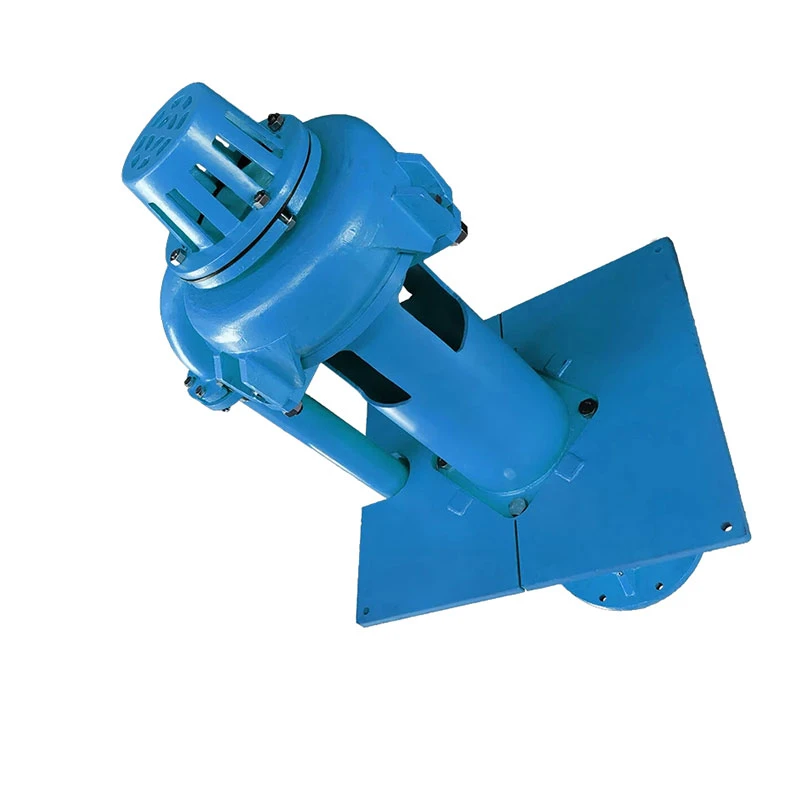

Pump Wear Parts G10110 Metal

Unlocking the Potential of Stainless Steel Water Pump Impellers A Comprehensive Guide

Moreover, leading manufacturers often contribute to broader knowledge through research and collaborations with academic institutions. Sharing insights through publications, white papers, and industry conferences reinforces their credibility, establishing them as pioneers in material innovation and pump efficiency. Trustworthiness, a vital component of any thriving partnership, is built over years of consistent performance and client satisfaction. For instance, having a proven track record and providing excellent customer support assures clients they are investing in a solution, not just a product. This is further solidified by offering warranties and after-sale services that demonstrate a manufacturer’s confidence in their impellers' durability and efficacy. The evolution of stainless steel water pump impellers is aligned with technological advancements such as computational fluid dynamics (CFD) simulations. These tools allow for designing more efficient and effective flow paths, which enhance the performance of impellers under varying operational conditions. The continual innovation ensures that these components not only keep pace with but lead the way in sustainable and efficient fluid management solutions. Innovations in smart technology have also led to the integration of condition monitoring systems within pump units, allowing real-time performance analytics of stainless steel impellers. Predictive maintenance, enabled by data gleaned from these systems, allows operators to preempt failure, ensuring seamless operations and extending the lifespan of equipment. In conclusion, stainless steel water pump impellers are at the intersection of strength, efficiency, and innovation. They offer notable advantages over their counterparts in terms of reliability and performance, securing their position as a preferred choice for modern industrial applications. Whether tackling the corrosive environments of chemical processing or the rigorous demands of municipal water systems, these impellers are crafted to deliver consistent results, establishing a benchmark for excellence in the fluid machinery arena. By leveraging cutting-edge engineering, maintaining rigorous quality standards, and fostering trust through proven performance, stainless steel water pump impellers epitomize an investment in durability and efficiency. This article serves not just as a guide but as an assurance of the choices industry leaders make when reliability and performance are imperative.

Moreover, leading manufacturers often contribute to broader knowledge through research and collaborations with academic institutions. Sharing insights through publications, white papers, and industry conferences reinforces their credibility, establishing them as pioneers in material innovation and pump efficiency. Trustworthiness, a vital component of any thriving partnership, is built over years of consistent performance and client satisfaction. For instance, having a proven track record and providing excellent customer support assures clients they are investing in a solution, not just a product. This is further solidified by offering warranties and after-sale services that demonstrate a manufacturer’s confidence in their impellers' durability and efficacy. The evolution of stainless steel water pump impellers is aligned with technological advancements such as computational fluid dynamics (CFD) simulations. These tools allow for designing more efficient and effective flow paths, which enhance the performance of impellers under varying operational conditions. The continual innovation ensures that these components not only keep pace with but lead the way in sustainable and efficient fluid management solutions. Innovations in smart technology have also led to the integration of condition monitoring systems within pump units, allowing real-time performance analytics of stainless steel impellers. Predictive maintenance, enabled by data gleaned from these systems, allows operators to preempt failure, ensuring seamless operations and extending the lifespan of equipment. In conclusion, stainless steel water pump impellers are at the intersection of strength, efficiency, and innovation. They offer notable advantages over their counterparts in terms of reliability and performance, securing their position as a preferred choice for modern industrial applications. Whether tackling the corrosive environments of chemical processing or the rigorous demands of municipal water systems, these impellers are crafted to deliver consistent results, establishing a benchmark for excellence in the fluid machinery arena. By leveraging cutting-edge engineering, maintaining rigorous quality standards, and fostering trust through proven performance, stainless steel water pump impellers epitomize an investment in durability and efficiency. This article serves not just as a guide but as an assurance of the choices industry leaders make when reliability and performance are imperative.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024