-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 13, 2025 06:10

Back to list

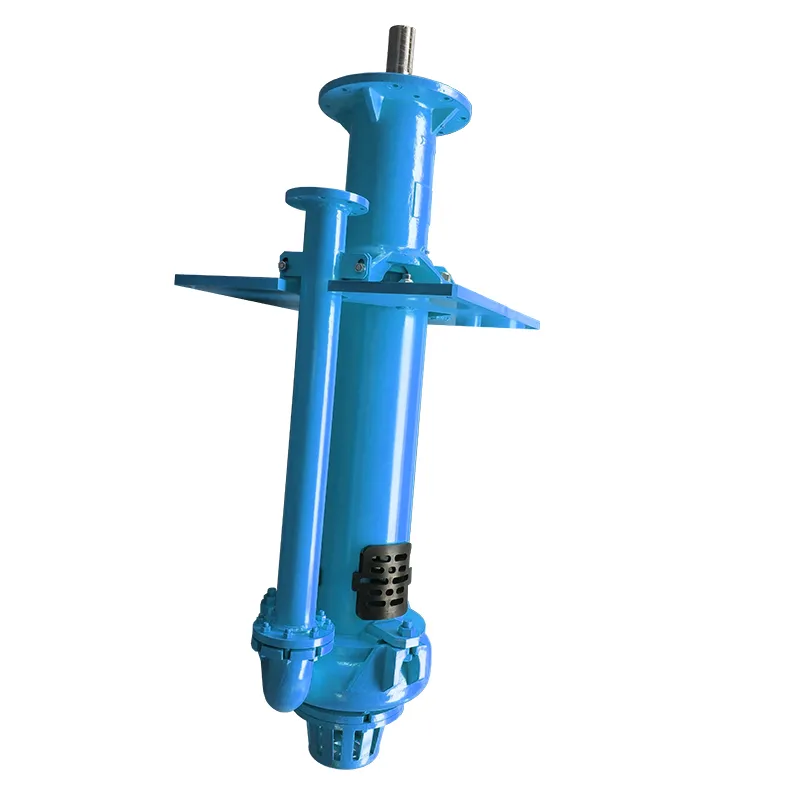

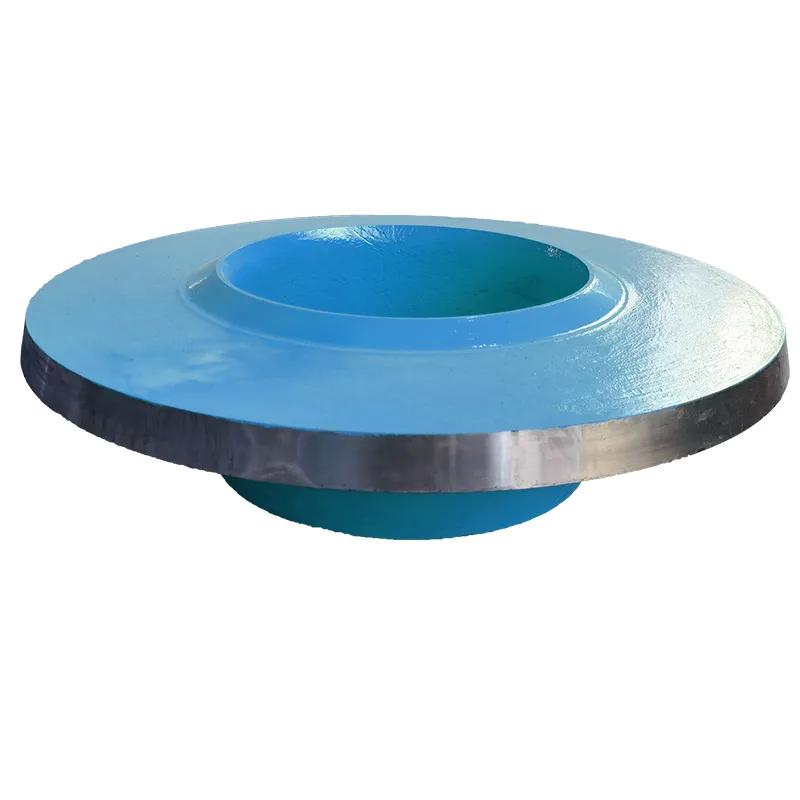

Pump Wear Parts E4058 Metal

The stainless steel impeller pump has long been an essential tool across various industries, offering unparalleled reliability and efficiency. Its robust construction and corrosion-resistant properties make it ideal for situations demanding durability against harsh environments. This article delves into the specifics of stainless steel impeller pumps, exploring their applications, benefits, and the expertise needed to choose the right one for your needs.

Authoritative insight into the manufacturing process of stainless steel impeller pumps reveals meticulous engineering and quality control. The precision casting of the impeller and pump casing requires advanced technology and skilled craftsmanship. These pumps often undergo rigorous testing to meet industry standards, guaranteeing that they can withstand real-world applications. Manufacturer reputation and certifications also play an influential role in establishing trustworthiness, ensuring that the pump is not only effective but also safe and compliant with global standards. The global reliance on stainless steel impeller pumps extends to their role in environmental sustainability. Water treatment plants use these pumps to process large volumes of water, essential in providing clean potable water and treating wastewater. The efficiency and reliability of these pumps contribute to reducing energy consumption and promoting effective waste management, aligning with global efforts toward environmental preservation. For industries looking to innovate and improve their processes, staying updated with the latest advancements in pump technology is crucial. Modern stainless steel impeller pumps incorporate smart technologies that allow for real-time monitoring and adjustments. IoT-enabled systems provide valuable data on pump performance, enabling predictive maintenance and reducing the risk of unexpected failures. This level of innovation enhances the pump’s reliability, making it a critical component in industrial operations' success. In conclusion, stainless steel impeller pumps exemplify the perfect blend of experience, expertise, authoritative craftsmanship, and trustworthiness. Their ability to handle a wide range of industrial applications while maintaining high-efficiency levels stands testament to the material's superiority and engineering excellence. Whether for new installations or upgrading existing systems, these pumps offer a good balance of performance, longevity, and environmental benefit, solidifying their place as an indispensable asset in the world of industrial pumps.

Authoritative insight into the manufacturing process of stainless steel impeller pumps reveals meticulous engineering and quality control. The precision casting of the impeller and pump casing requires advanced technology and skilled craftsmanship. These pumps often undergo rigorous testing to meet industry standards, guaranteeing that they can withstand real-world applications. Manufacturer reputation and certifications also play an influential role in establishing trustworthiness, ensuring that the pump is not only effective but also safe and compliant with global standards. The global reliance on stainless steel impeller pumps extends to their role in environmental sustainability. Water treatment plants use these pumps to process large volumes of water, essential in providing clean potable water and treating wastewater. The efficiency and reliability of these pumps contribute to reducing energy consumption and promoting effective waste management, aligning with global efforts toward environmental preservation. For industries looking to innovate and improve their processes, staying updated with the latest advancements in pump technology is crucial. Modern stainless steel impeller pumps incorporate smart technologies that allow for real-time monitoring and adjustments. IoT-enabled systems provide valuable data on pump performance, enabling predictive maintenance and reducing the risk of unexpected failures. This level of innovation enhances the pump’s reliability, making it a critical component in industrial operations' success. In conclusion, stainless steel impeller pumps exemplify the perfect blend of experience, expertise, authoritative craftsmanship, and trustworthiness. Their ability to handle a wide range of industrial applications while maintaining high-efficiency levels stands testament to the material's superiority and engineering excellence. Whether for new installations or upgrading existing systems, these pumps offer a good balance of performance, longevity, and environmental benefit, solidifying their place as an indispensable asset in the world of industrial pumps.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024