-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 02:22

Back to list

Pump Wear Parts SP15041 Metal

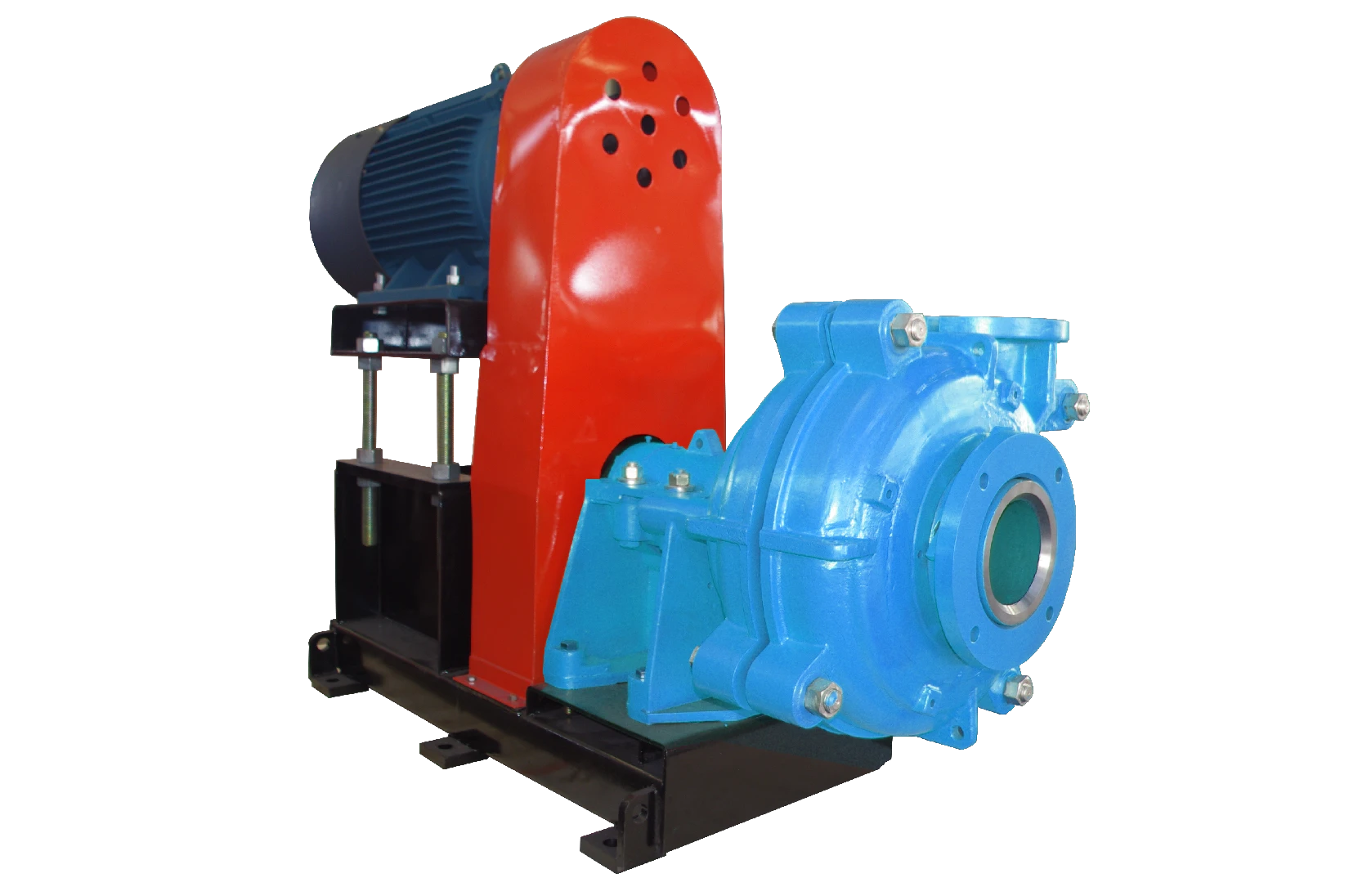

In the world of industrial processes, the slurry transfer pump plays a pivotal role in ensuring efficiency and effectiveness. Known for their robustness and flexibility, these pumps are essential in sectors ranging from mining to wastewater treatment. Here’s an in-depth exploration of slurry transfer pumps, drawing on expertise, authority, and trust, essential for industries that rely on them for seamless operations.

Expertise further dictates the importance of proper installation and configuration of slurry transfer pumps. Misalignment of pumps is a common problem that can lead to seal leaks and subsequent inefficiencies. Professional installation ensures that all components, including the base plate and motor alignment, are meticulously set to mitigate operational setbacks. Proper training for the staff operating these pumps reinforces this setup, affording companies a seamless process flow free from frequent downtime. Authoritativeness in the domain of slurry transfer indicates recognizing innovative technological advancements. Modern pumps are equipped with IoT capabilities, allowing for real-time monitoring and diagnostics. These smart pumps can anticipate component wear, notify operators of potential failures, and suggest timely maintenance schedules. By adopting technology-enhanced pumps, industries not only increase operational efficiency but also bolster their environmental compliance credentials. Reducing waste and optimizing resource usage reflect a company’s commitment to sustainable operational practices. Trustworthiness surrounding slurry transfer pumps hinges on transparency and reliability of service. Engaging with reputable manufacturers known for rigorous quality assurance processes ensures the delivery of reliable products. Furthermore, competent after-sales support offering routine service and emergency repairs fosters trust and builds lasting business relationships. Companies that prioritize thorough documentation and transparent communication regarding pump capabilities and limitations often build enduring client trust. In conclusion, the slurry transfer pump is more than just a piece of equipment; it is a critical cog in the machinery of industries reliant on efficient materials handling. Mastery over the nuances of slurry transfer pumps brings about enhanced operational efficacy, longevity of equipment, and improved bottom lines. With knowledge derived from years of practical experience, expert guidance on the right pump choice, staying abreast of cutting-edge technological developments, and fostering trust through reliability, businesses can optimize their operations significantly. Recognizing these factors in the selection and operation of slurry transfer pumps illuminates pathways to refined industry practices, underscoring the integral role these pumps play in modern industrial success.

Expertise further dictates the importance of proper installation and configuration of slurry transfer pumps. Misalignment of pumps is a common problem that can lead to seal leaks and subsequent inefficiencies. Professional installation ensures that all components, including the base plate and motor alignment, are meticulously set to mitigate operational setbacks. Proper training for the staff operating these pumps reinforces this setup, affording companies a seamless process flow free from frequent downtime. Authoritativeness in the domain of slurry transfer indicates recognizing innovative technological advancements. Modern pumps are equipped with IoT capabilities, allowing for real-time monitoring and diagnostics. These smart pumps can anticipate component wear, notify operators of potential failures, and suggest timely maintenance schedules. By adopting technology-enhanced pumps, industries not only increase operational efficiency but also bolster their environmental compliance credentials. Reducing waste and optimizing resource usage reflect a company’s commitment to sustainable operational practices. Trustworthiness surrounding slurry transfer pumps hinges on transparency and reliability of service. Engaging with reputable manufacturers known for rigorous quality assurance processes ensures the delivery of reliable products. Furthermore, competent after-sales support offering routine service and emergency repairs fosters trust and builds lasting business relationships. Companies that prioritize thorough documentation and transparent communication regarding pump capabilities and limitations often build enduring client trust. In conclusion, the slurry transfer pump is more than just a piece of equipment; it is a critical cog in the machinery of industries reliant on efficient materials handling. Mastery over the nuances of slurry transfer pumps brings about enhanced operational efficacy, longevity of equipment, and improved bottom lines. With knowledge derived from years of practical experience, expert guidance on the right pump choice, staying abreast of cutting-edge technological developments, and fostering trust through reliability, businesses can optimize their operations significantly. Recognizing these factors in the selection and operation of slurry transfer pumps illuminates pathways to refined industry practices, underscoring the integral role these pumps play in modern industrial success.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024