-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 01:58

Back to list

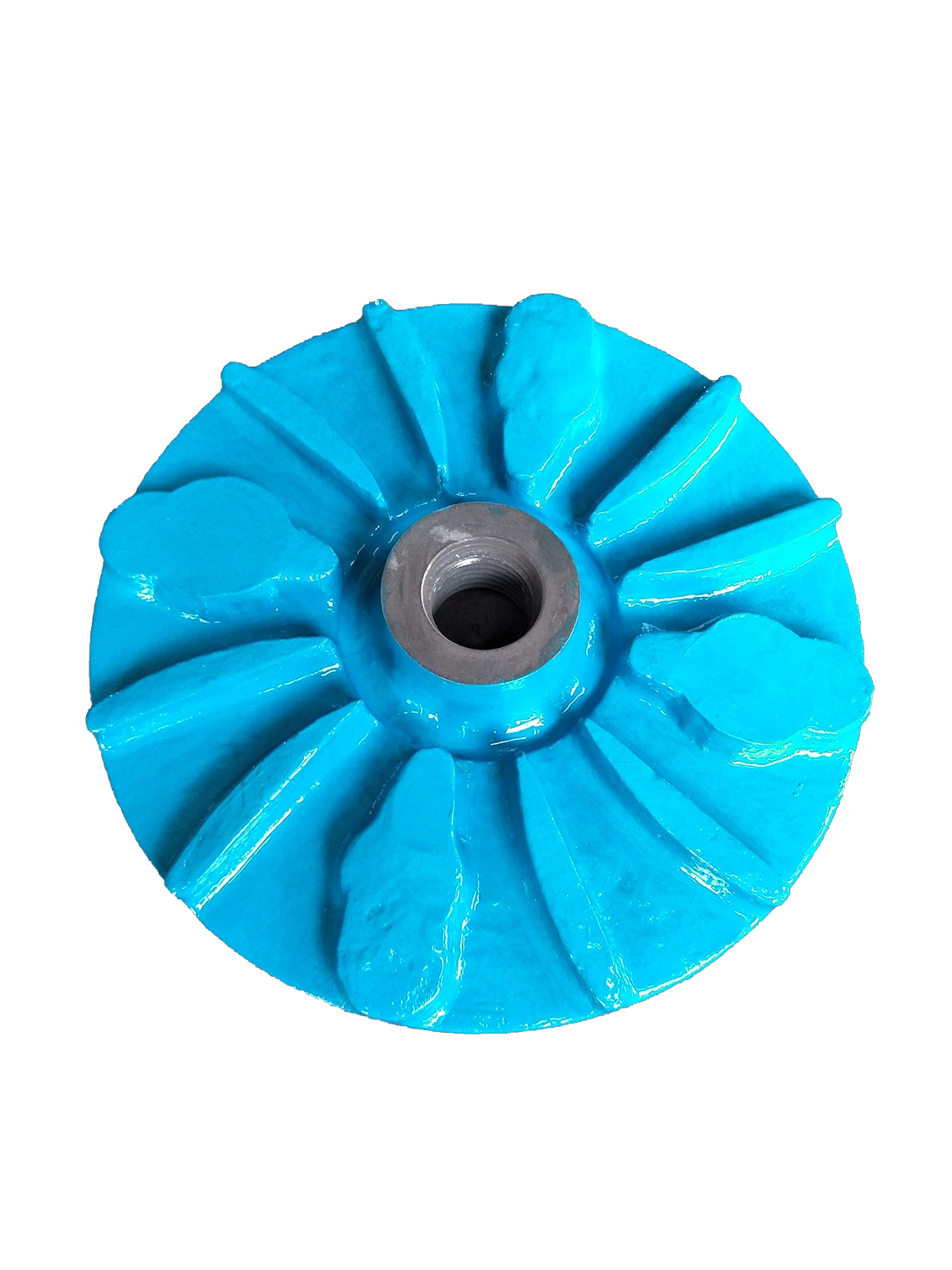

Pump Wear Parts EH3110 Metal

Efficient slurry transport using centrifugal pumps is a critical process in industries such as mining, wastewater treatment, and dredging. The complexities involved in transporting slurry, which is a mixture of solid particles and liquid, require a combination of engineering expertise and practical experience to ensure system reliability, longevity, and cost-effectiveness.

Expert maintenance is another pillar of effective slurry transport. Regular inspections, timely replacement of wear parts, and predictive maintenance are strategies that seasoned professionals swear by. For instance, using condition monitoring equipment to track vibrations and temperature can preempt failures, a piece of advice grounded in both authoritative studies and practical field experience. Moreover, incorporating reliable seals and bearings that can endure the corrosive and abrasive nature of slurry significantly bolsters the trustworthiness of the entire operation. A wise choice in seal technology, such as mechanical seals over packing seals, provides a higher reliability factor, preventing leakage and the associated risks. Finally, the layout of the slurry transport system greatly influences its efficiency. Experienced engineers advocate for minimizing bends and ensuring pipeline integrity to limit the pressure head losses and potential clogs. Designing with gradual transitions and strategic placement of booster pumps helps maintain an uninterrupted flow, as corroborated by numerous case studies and professional recommendations. In conclusion, the intricate process of slurry transport using centrifugal pumps is best managed by leveraging both engineering expertise and real-world insights. Through careful selection, strategic maintenance, and innovative design, these systems can deliver consistent performance, embodying the hallmarks of experience, expertise, authority, and trust. With the right approach, companies can ensure their operations are both economically efficient and environmentally sustainable.

Expert maintenance is another pillar of effective slurry transport. Regular inspections, timely replacement of wear parts, and predictive maintenance are strategies that seasoned professionals swear by. For instance, using condition monitoring equipment to track vibrations and temperature can preempt failures, a piece of advice grounded in both authoritative studies and practical field experience. Moreover, incorporating reliable seals and bearings that can endure the corrosive and abrasive nature of slurry significantly bolsters the trustworthiness of the entire operation. A wise choice in seal technology, such as mechanical seals over packing seals, provides a higher reliability factor, preventing leakage and the associated risks. Finally, the layout of the slurry transport system greatly influences its efficiency. Experienced engineers advocate for minimizing bends and ensuring pipeline integrity to limit the pressure head losses and potential clogs. Designing with gradual transitions and strategic placement of booster pumps helps maintain an uninterrupted flow, as corroborated by numerous case studies and professional recommendations. In conclusion, the intricate process of slurry transport using centrifugal pumps is best managed by leveraging both engineering expertise and real-world insights. Through careful selection, strategic maintenance, and innovative design, these systems can deliver consistent performance, embodying the hallmarks of experience, expertise, authority, and trust. With the right approach, companies can ensure their operations are both economically efficient and environmentally sustainable.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024