-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 18, 2025 02:39

Back to list

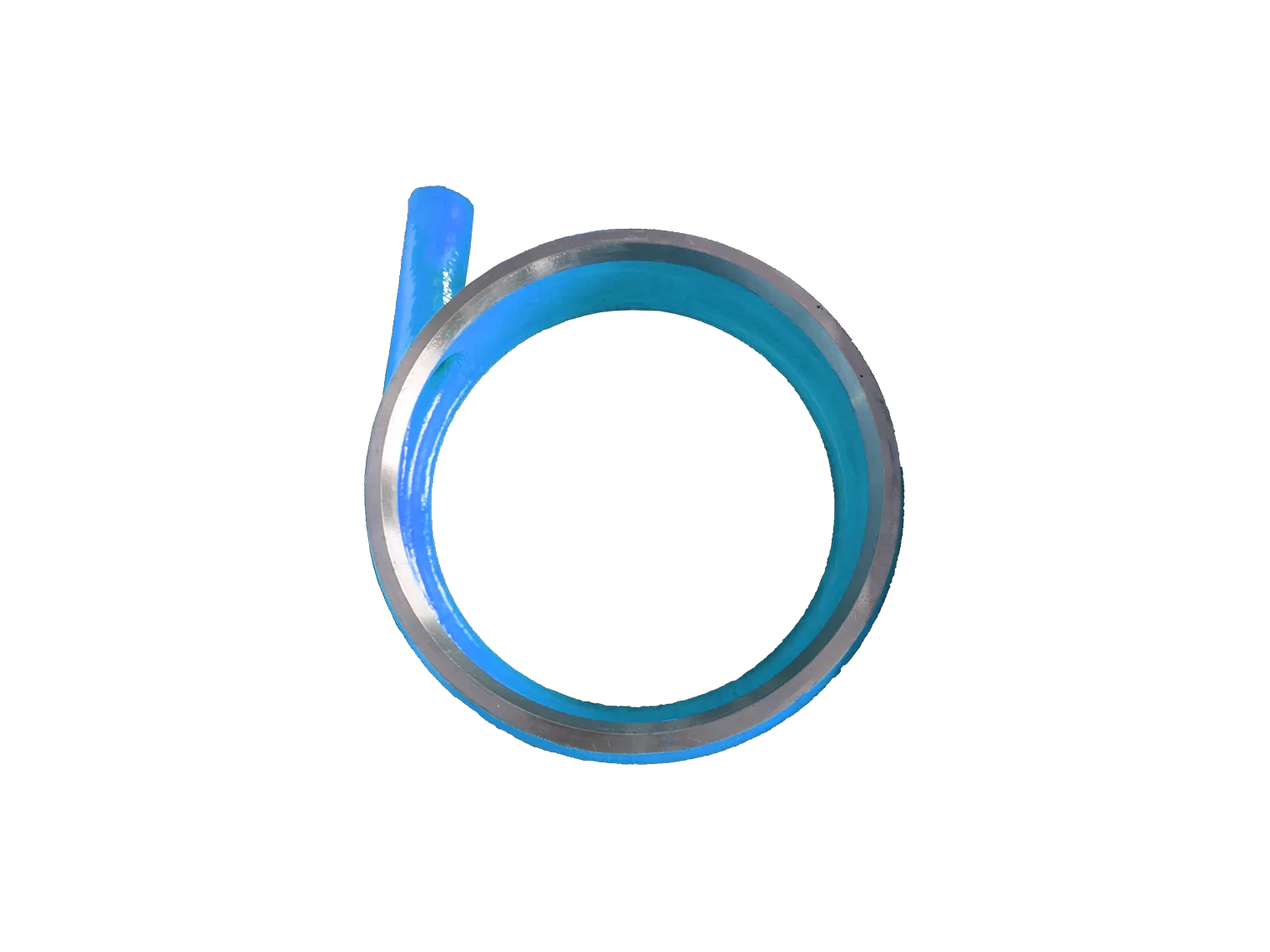

Pump Wear Parts Stl400110 Sheath

Mining slurry pumps are an essential component in the extraction and processing industries, serving as the lifeline in transporting abrasive and corrosive slurries. Their performance and reliability directly influence the efficiency of mining operations, and investing in high-quality slurry pumps is crucial for any enterprise aiming to optimize its operations.

The authoritativeness of manufacturers in the slurry pump market heavily impacts the perception of product quality and reliability. Leading companies in this sector invest heavily in research and development to innovate designs that cater to the industry's evolving demands. Their authority is built on decades of experience and a track record of delivering products that consistently meet the rigorous standards of mining operations worldwide. This commitment to innovation and quality ensures they remain at the forefront of technology, offering pumps that stand the test of time. Trustworthiness in the form of comprehensive after-sales services enhances user confidence. Manufacturers that provide extended warranties, customer service, and on-site support amplify their trust in their products, reassuring customers of their investment's value. The availability of replacement parts and service technicians globally also plays a significant role in fostering a trusting relationship between suppliers and end-users. Selecting the right mining slurry pump requires careful consideration of the specific requirements dictated by the mining operation. Firms are advised to conduct detailed operational analyses to pinpoint their exact needs. Factors such as required flow rates, the nature of the slurry, and the operational environment should guide the selection process, ensuring that the chosen pump aligns perfectly with operational goals. In conclusion, mining slurry pumps are not just pieces of equipment; they are critical components that directly affect the productivity and cost-effectiveness of mining operations. With a focus on experience, technological expertise, manufacturer authority, and product trustworthiness, mining enterprises can significantly enhance their operational capacity while also achieving sustainable cost management.

The authoritativeness of manufacturers in the slurry pump market heavily impacts the perception of product quality and reliability. Leading companies in this sector invest heavily in research and development to innovate designs that cater to the industry's evolving demands. Their authority is built on decades of experience and a track record of delivering products that consistently meet the rigorous standards of mining operations worldwide. This commitment to innovation and quality ensures they remain at the forefront of technology, offering pumps that stand the test of time. Trustworthiness in the form of comprehensive after-sales services enhances user confidence. Manufacturers that provide extended warranties, customer service, and on-site support amplify their trust in their products, reassuring customers of their investment's value. The availability of replacement parts and service technicians globally also plays a significant role in fostering a trusting relationship between suppliers and end-users. Selecting the right mining slurry pump requires careful consideration of the specific requirements dictated by the mining operation. Firms are advised to conduct detailed operational analyses to pinpoint their exact needs. Factors such as required flow rates, the nature of the slurry, and the operational environment should guide the selection process, ensuring that the chosen pump aligns perfectly with operational goals. In conclusion, mining slurry pumps are not just pieces of equipment; they are critical components that directly affect the productivity and cost-effectiveness of mining operations. With a focus on experience, technological expertise, manufacturer authority, and product trustworthiness, mining enterprises can significantly enhance their operational capacity while also achieving sustainable cost management.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024