-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 05, 2025 01:46

Back to list

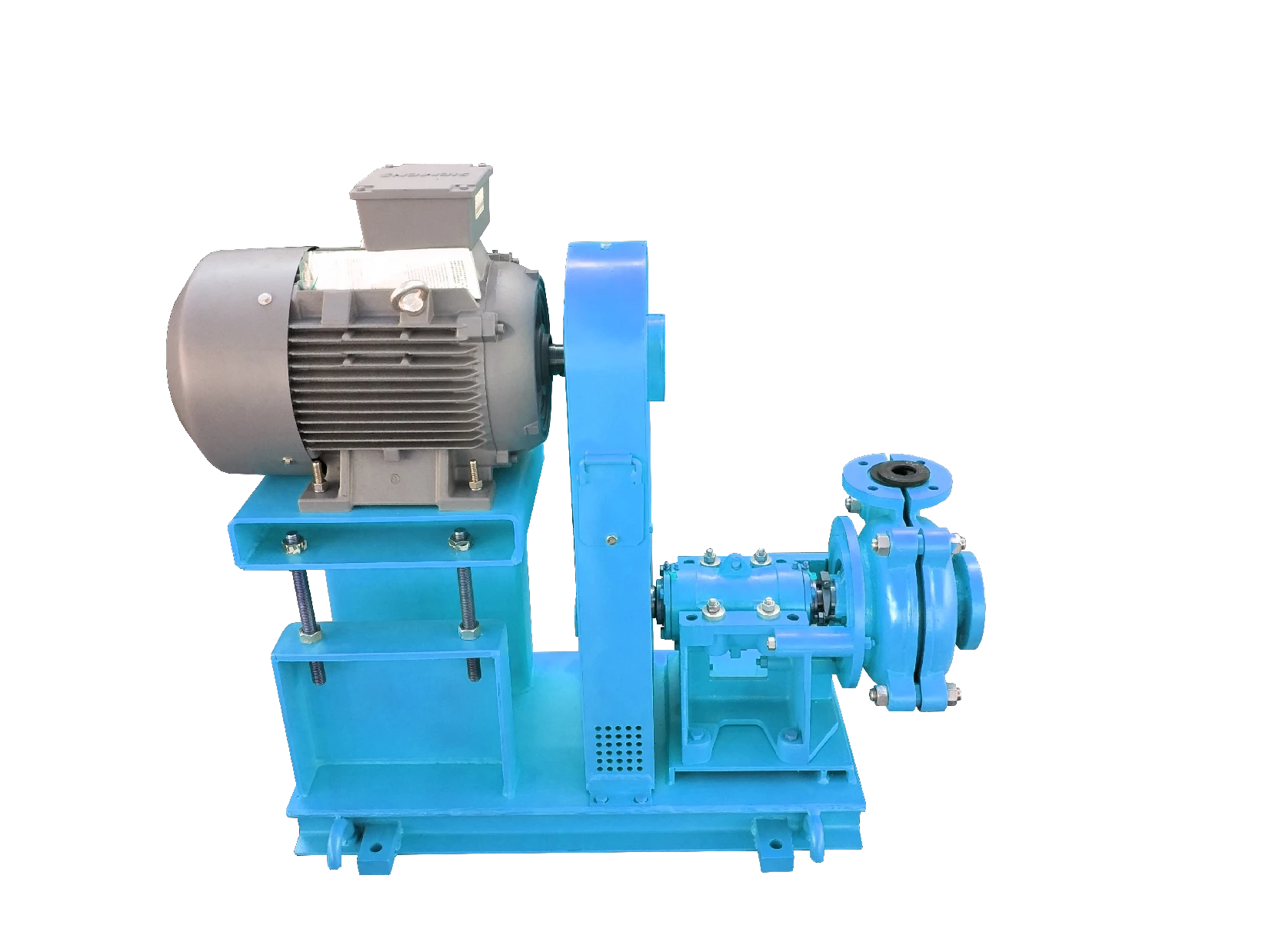

pump wear ring

When it comes to maximizing the performance and longevity of pumps, selecting the right components is crucial. Among these components, the pump wear ring plays an indispensable role. Often overlooked, this integral element affects not just efficiency but also the operational lifespan of the pump itself.

Authoritativeness in the field of pump wear rings is characterized by innovation and adherence to global standards. Leading manufacturers not only meet but often set the benchmarks for durability and performance. This authority is cemented through years of research and development, ensuring that when a pump wear ring is installed, it delivers on its promise of extended service life and efficiency. Building trust in the reliability of pump wear rings involves more than just product design and material selection. It includes rigorous testing, proper certification, and real-world performance data. Trusted brands in the marketplace offer comprehensive warranty packages and have a proven track record of customer satisfaction. Moreover, they provide detailed installation guides and offer support from qualified professionals, ensuring that their products function optimally under recommended conditions. Ultimately, the choice of a pump wear ring should never be taken lightly. When selecting these components, consider factors such as the specific environment in which the pump operates, potential chemical interactions, and the overall design of the pump. Consulting with professionals who possess specialized knowledge can provide insights that lead to more informed decisions. This expertise translates into not only cost savings in terms of reduced maintenance but also enhanced reliability and efficiency in pump operation. To summarize, understanding the importance of pump wear rings involves recognizing their role in maintaining efficiency, protecting key components, and extending the life of pumps. Trustworthy manufacturers who uphold stringent standards and offer expert guidance can ensure that your pumps operate at their best, delivering sustainable performance for your business operations. As you navigate options for pump wear rings, consider this combination of experience, expertise, authoritativeness, and trustworthiness to guide your choice for optimal outcomes.

Authoritativeness in the field of pump wear rings is characterized by innovation and adherence to global standards. Leading manufacturers not only meet but often set the benchmarks for durability and performance. This authority is cemented through years of research and development, ensuring that when a pump wear ring is installed, it delivers on its promise of extended service life and efficiency. Building trust in the reliability of pump wear rings involves more than just product design and material selection. It includes rigorous testing, proper certification, and real-world performance data. Trusted brands in the marketplace offer comprehensive warranty packages and have a proven track record of customer satisfaction. Moreover, they provide detailed installation guides and offer support from qualified professionals, ensuring that their products function optimally under recommended conditions. Ultimately, the choice of a pump wear ring should never be taken lightly. When selecting these components, consider factors such as the specific environment in which the pump operates, potential chemical interactions, and the overall design of the pump. Consulting with professionals who possess specialized knowledge can provide insights that lead to more informed decisions. This expertise translates into not only cost savings in terms of reduced maintenance but also enhanced reliability and efficiency in pump operation. To summarize, understanding the importance of pump wear rings involves recognizing their role in maintaining efficiency, protecting key components, and extending the life of pumps. Trustworthy manufacturers who uphold stringent standards and offer expert guidance can ensure that your pumps operate at their best, delivering sustainable performance for your business operations. As you navigate options for pump wear rings, consider this combination of experience, expertise, authoritativeness, and trustworthiness to guide your choice for optimal outcomes.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024