-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 05, 2025 01:23

Back to list

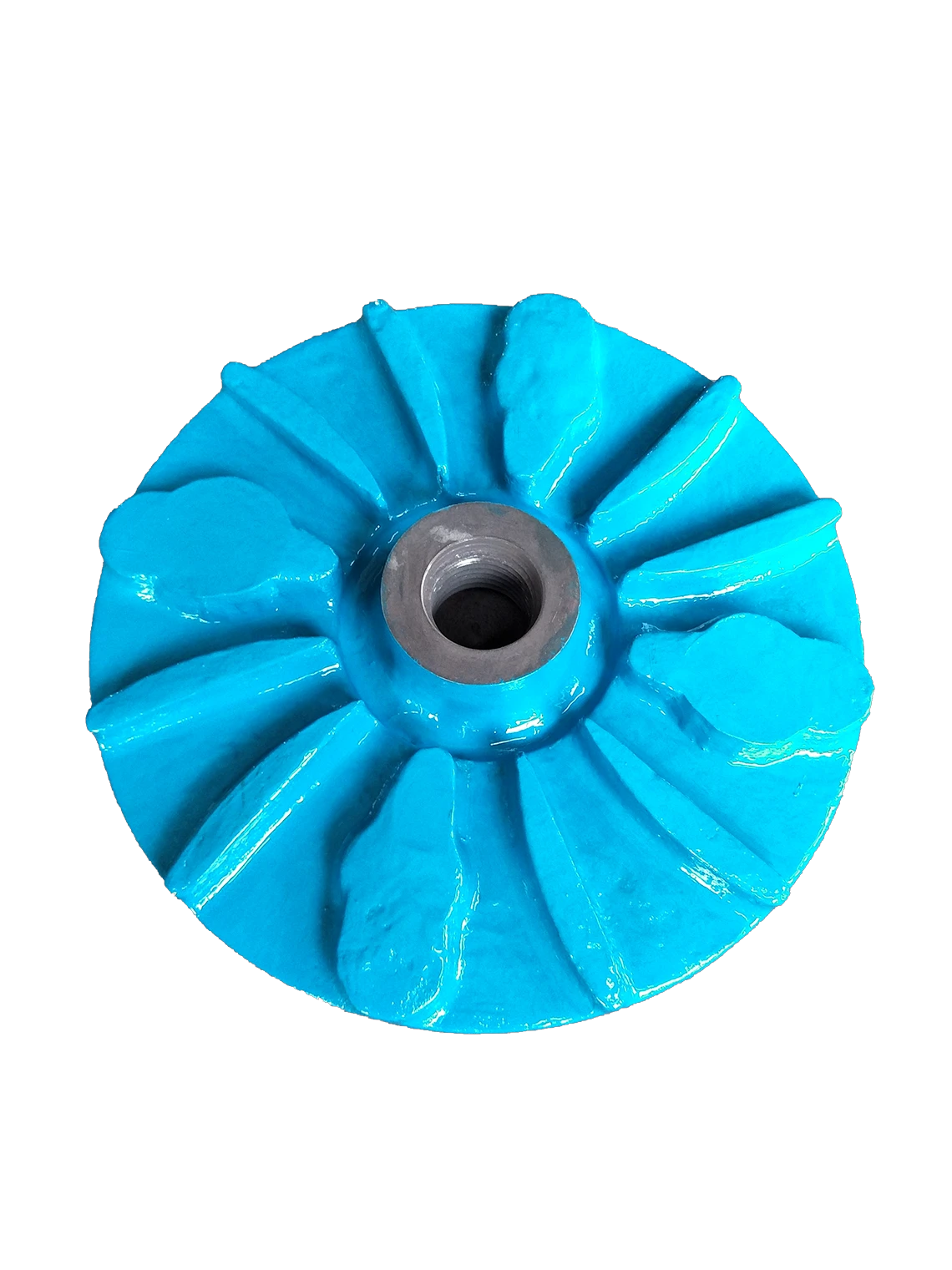

pump wear parts

In the world of industrial equipment, maintaining the efficacy and longevity of machinery is paramount for any operation. When it comes to pumps, one of the critical components ensuring their performance are the pump wear parts. These parts, though often overshadowed by more conspicuous elements of machinery, play an indispensable role in the functionality and efficiency of pumping systems across various industries. Understanding their importance, selection, and maintenance can significantly impact an organization's operational success.

Trustworthiness in this domain is established through consistent performance and reliability. Companies with a reputation for providing durable and effective wear parts build trust not only through product excellence but also through exceptional support and customer service. A trustworthy supplier will offer comprehensive guidance on installation, performance optimization, and predictive maintenance strategies that can prevent operational interruptions and extend the lifespan of pump wear parts. Real-world experience is a critical factor in ensuring that pump wear parts function as intended. This involves not only the empirical evidence of their durability in field applications but also a continuous feedback loop with users. By incorporating data from actual usage and aligning with technological advancements, manufacturers and suppliers can refine their products and offer solutions that are tailored to specific operational needs, thus enhancing the overall efficiency and reliability of pumping systems. The authority of any entity supplying pump wear parts can be measured by its contribution to advancements in the field. Companies that invest in research and development, collaborate with academic institutions, or participate in industry standards organizations often lead the way in innovation. Their authority is reflected in the development of cutting-edge materials and designs that push the boundaries of what pump wear parts can achieve, thereby setting new standards for the industry. In conclusion, pump wear parts are the unsung heroes of efficient and reliable pump operation. Their selection and maintenance require a blend of experience, expertise, authority, and trustworthiness. By prioritizing these qualities, industrial operations can safeguard against unexpected failures, reduce maintenance costs, and ensure smooth continuous operation, thereby reinforcing their competitive edge in the marketplace. Understanding the nuanced interplay between these factors not only optimizes pump performance but also contributes to the sustainable success of enterprises that depend on these critical systems.

Trustworthiness in this domain is established through consistent performance and reliability. Companies with a reputation for providing durable and effective wear parts build trust not only through product excellence but also through exceptional support and customer service. A trustworthy supplier will offer comprehensive guidance on installation, performance optimization, and predictive maintenance strategies that can prevent operational interruptions and extend the lifespan of pump wear parts. Real-world experience is a critical factor in ensuring that pump wear parts function as intended. This involves not only the empirical evidence of their durability in field applications but also a continuous feedback loop with users. By incorporating data from actual usage and aligning with technological advancements, manufacturers and suppliers can refine their products and offer solutions that are tailored to specific operational needs, thus enhancing the overall efficiency and reliability of pumping systems. The authority of any entity supplying pump wear parts can be measured by its contribution to advancements in the field. Companies that invest in research and development, collaborate with academic institutions, or participate in industry standards organizations often lead the way in innovation. Their authority is reflected in the development of cutting-edge materials and designs that push the boundaries of what pump wear parts can achieve, thereby setting new standards for the industry. In conclusion, pump wear parts are the unsung heroes of efficient and reliable pump operation. Their selection and maintenance require a blend of experience, expertise, authority, and trustworthiness. By prioritizing these qualities, industrial operations can safeguard against unexpected failures, reduce maintenance costs, and ensure smooth continuous operation, thereby reinforcing their competitive edge in the marketplace. Understanding the nuanced interplay between these factors not only optimizes pump performance but also contributes to the sustainable success of enterprises that depend on these critical systems.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024