-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 05, 2025 02:10

Back to list

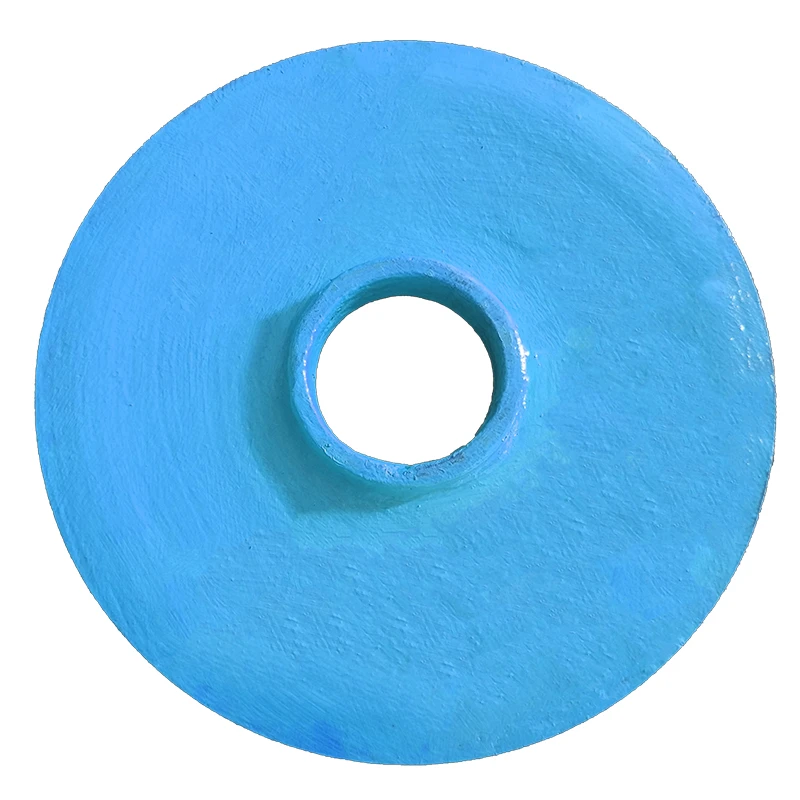

casing wear ring and impeller wear ring

Casing wear rings and impeller wear rings play crucial roles in the efficiency and longevity of centrifugal pumps, which are used extensively across multiple industries, including water treatment, oil refinery, and chemical processing. Understanding the function, materials, and maintenance of these components can significantly enhance system performance and reduce operational costs.

In terms of technological advancements, the development of new composite materials and coatings offers significant advantages. For example, the use of ceramic coatings can enhance wear resistance and reduce friction, thus extending the service life of both the casing and impeller wear rings. Such innovations are worth considering when looking to optimize pump performance and minimize lifecycle costs. When designing a system or selecting pump components, consulting with engineers who specialize in fluid dynamics or a professional with extensive experience in pump design and maintenance is advisable. Their expertise can provide insights into the best practices for your specific application, ensuring that all components, including the wear rings, are optimally selected. Moreover, authoritative sources such as international standards and manufacturer guidelines can serve as reliable references for best practices in the installation, maintenance, and operation of wear rings. Adherence to such guidelines not only enhances performance but also ensures safety and compliance with industry regulations. Trust in the longevity and performance of centrifugal pumps can also be built by relying on reputable manufacturers known for high-quality materials and precise engineering in their wear rings. Their reputation and track record can be valuable indicators of the reliability you can expect from their products. In conclusion, the strategic selection and diligent maintenance of casing wear rings and impeller wear rings are indispensable for ensuring the optimal and cost-effective operation of centrifugal pumps. By focusing on quality materials, advanced predictive maintenance, and industry expertise, businesses can significantly enhance the efficiency and reliability of their pumping systems, leading to substantial financial and operational benefits.

In terms of technological advancements, the development of new composite materials and coatings offers significant advantages. For example, the use of ceramic coatings can enhance wear resistance and reduce friction, thus extending the service life of both the casing and impeller wear rings. Such innovations are worth considering when looking to optimize pump performance and minimize lifecycle costs. When designing a system or selecting pump components, consulting with engineers who specialize in fluid dynamics or a professional with extensive experience in pump design and maintenance is advisable. Their expertise can provide insights into the best practices for your specific application, ensuring that all components, including the wear rings, are optimally selected. Moreover, authoritative sources such as international standards and manufacturer guidelines can serve as reliable references for best practices in the installation, maintenance, and operation of wear rings. Adherence to such guidelines not only enhances performance but also ensures safety and compliance with industry regulations. Trust in the longevity and performance of centrifugal pumps can also be built by relying on reputable manufacturers known for high-quality materials and precise engineering in their wear rings. Their reputation and track record can be valuable indicators of the reliability you can expect from their products. In conclusion, the strategic selection and diligent maintenance of casing wear rings and impeller wear rings are indispensable for ensuring the optimal and cost-effective operation of centrifugal pumps. By focusing on quality materials, advanced predictive maintenance, and industry expertise, businesses can significantly enhance the efficiency and reliability of their pumping systems, leading to substantial financial and operational benefits.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024