-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 19:07

Back to list

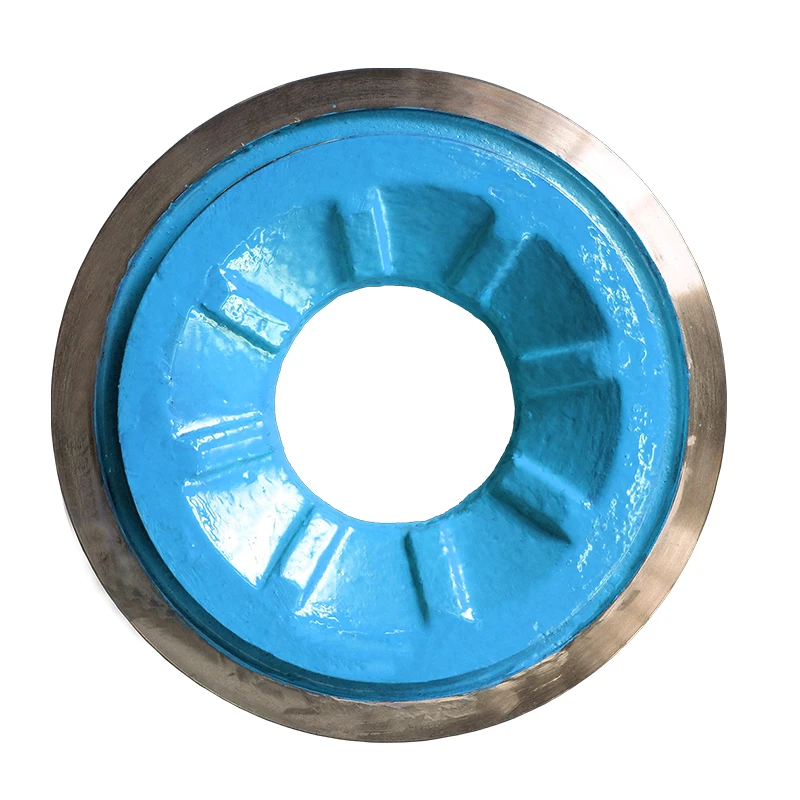

Pump Wear Parts G8018 Rubber

Understanding and choosing the right parts of a bearing assembly is crucial for ensuring the efficiency and longevity of machinery across various industries. This knowledge not only empowers professionals to maintain and repair equipment effectively but also makes sure that specific applications run smoothly and with minimal downtime. Here, we delve into the main components of a bearing assembly, offering insights from decades of hands-on experience and expertise.

The cage, or retainer, refers to the part that keeps the rolling elements evenly spaced. It prevents contact between them, reducing friction and wear. Cages made from materials like polyamide, steel, or brass are selected based on the operating conditions. A polyamide cage might be recommended for high-speed applications due to its lighter weight, while a brass cage may be chosen for its excellent resistance to corrosion in more demanding environments. Seals and shields are optional components that play a protective role, preventing contaminants such as dust and moisture from entering the bearing. Sealed or shielded bearings are preferred in applications where contamination poses a threat to the bearing's functionality. Expert knowledge in selecting the right type of seal or shield significantly enhances the assembly's lifespan by minimizing the ingress of harmful particles. Selecting the appropriate bearing assembly and its components can be a challenging task given the diversity of options available. However, adhering to industry standards and relying on authoritative sources can aid in making informed decisions. It’s crucial for professionals to not only understand the technical specifications of each component but also consider the operational environment to choose components that best suit their application. Moreover, the principles of reliability, performance, and efficiency must guide the selection and maintenance of bearing assemblies. This encompasses regular inspections, proper lubrication, and timely replacements of any worn-out parts, which are fundamental practices recommended by industry leaders. In conclusion, a thorough understanding of the parts of a bearing assembly is more than just academic knowledge; it is an essential component of successful machinery maintenance and performance enhancement. The expertise in selecting, assembling, and maintaining these components can be the deciding factor between prolonged machinery downtime and optimal uninterrupted performance. By incorporating trustworthy information and expertise in bearing technology, industries can significantly extend the life of their machinery and improve their operational efficiencies.

The cage, or retainer, refers to the part that keeps the rolling elements evenly spaced. It prevents contact between them, reducing friction and wear. Cages made from materials like polyamide, steel, or brass are selected based on the operating conditions. A polyamide cage might be recommended for high-speed applications due to its lighter weight, while a brass cage may be chosen for its excellent resistance to corrosion in more demanding environments. Seals and shields are optional components that play a protective role, preventing contaminants such as dust and moisture from entering the bearing. Sealed or shielded bearings are preferred in applications where contamination poses a threat to the bearing's functionality. Expert knowledge in selecting the right type of seal or shield significantly enhances the assembly's lifespan by minimizing the ingress of harmful particles. Selecting the appropriate bearing assembly and its components can be a challenging task given the diversity of options available. However, adhering to industry standards and relying on authoritative sources can aid in making informed decisions. It’s crucial for professionals to not only understand the technical specifications of each component but also consider the operational environment to choose components that best suit their application. Moreover, the principles of reliability, performance, and efficiency must guide the selection and maintenance of bearing assemblies. This encompasses regular inspections, proper lubrication, and timely replacements of any worn-out parts, which are fundamental practices recommended by industry leaders. In conclusion, a thorough understanding of the parts of a bearing assembly is more than just academic knowledge; it is an essential component of successful machinery maintenance and performance enhancement. The expertise in selecting, assembling, and maintaining these components can be the deciding factor between prolonged machinery downtime and optimal uninterrupted performance. By incorporating trustworthy information and expertise in bearing technology, industries can significantly extend the life of their machinery and improve their operational efficiencies.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024