-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 19:44

Back to list

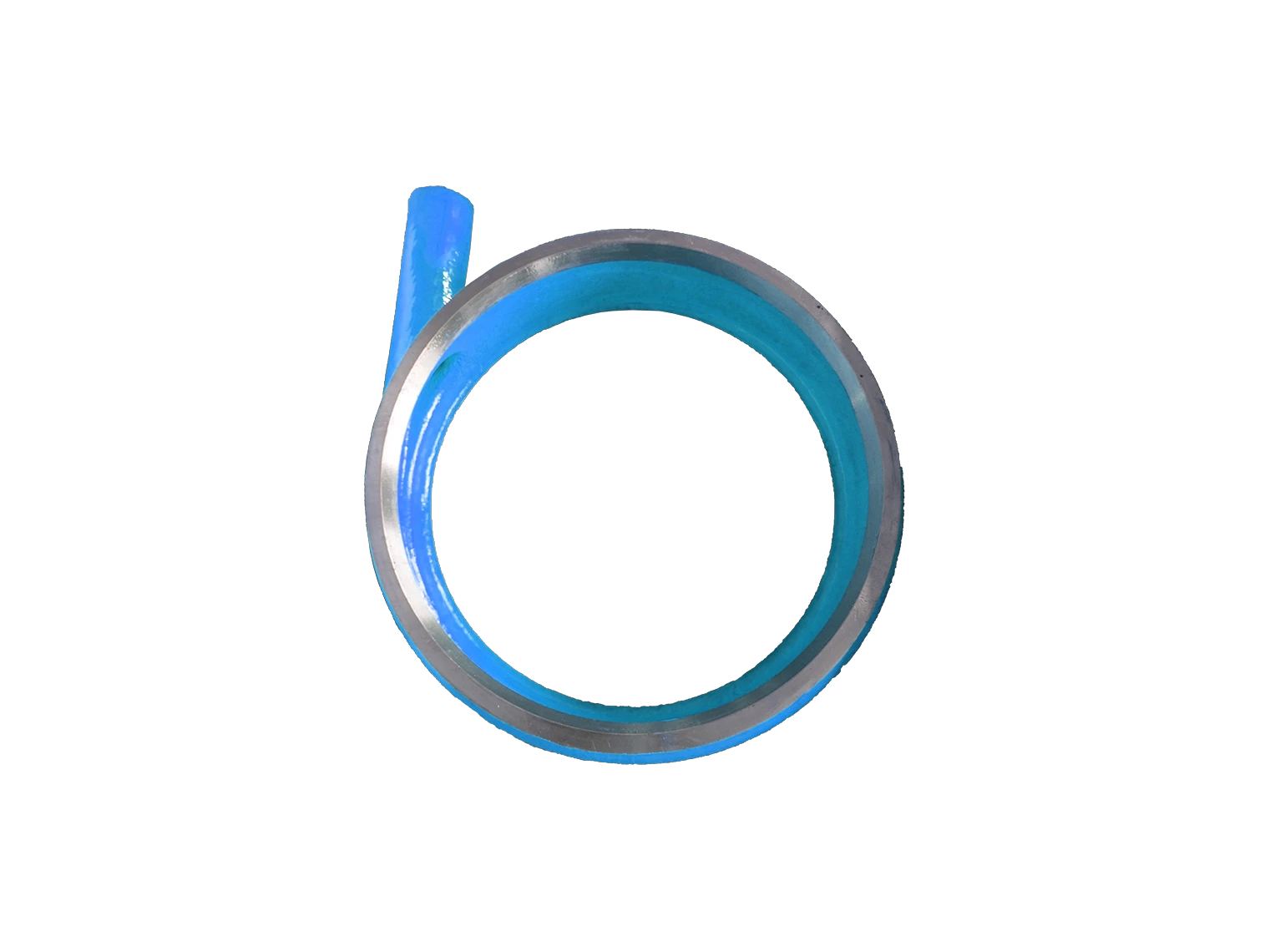

Pump Wear Parts STl40083 Front Guard

Understanding the intricacies of assembly bearings is crucial for businesses who seek efficiency and precision in their mechanical applications. An assembly bearing is not merely a mechanical component; it is a vital linchpin that ensures the seamless operation of intricate machine systems. With the growing demand for high-performance machinery in industries ranging from automotive to aerospace, selecting the right type of bearing becomes imperative for enhancing productivity and prolonging the lifecycle of equipment.

Authoritativeness in Assembly Bearing Innovation Through decades of development and research, the field of assembly bearings has seen incredible technological advancements. Leading brands have introduced self-aligning bearings and hybrid designs that incorporate sensors for predictive maintenance, ensuring constant monitoring of machine health. Industry leaders such as SKF and Schaeffler have set standards for innovation in this space, offering solutions that not only solve current mechanical challenges but also anticipate the evolving needs of modern industry. Their focus on research and development has paved the way for innovations like smart bearings, which interact with digital systems and contribute to the burgeoning field of industrial IoT. Trustworthiness and Reliability of Assembly Bearings Procuring assembly bearings from reputable manufacturers ensures high levels of reliability and trust. The quality control processes adopted by these manufacturers guarantee that each bearing meets rigorous standards before it reaches the market. Testimonials from global manufacturers affirm the critical role of quality assurance in selecting assembly bearings. A leading automotive company, for example, reported a significant reduction in warranty claims after switching to bearings from a trusted, certified supplier. Such reliability not only proves essential in maintaining product integrity but also builds consumer trust. In summary, the utilization of assembly bearings embodies a blend of engineering precision, empirical expertise, and innovative foresight. Businesses keen on achieving operational excellence would do well to invest in high-quality assembly bearings, understanding that these components are foundational to the integrity and efficiency of their machinery. By doing so, they not only ensure optimal performance and safety in their operations but also remain at the forefront of technological advancements in their respective industries. Overall, a strategic approach to integrating expertly selected assembly bearings positions companies for sustainable growth and competitive advantage in a rapidly evolving technological landscape.

Authoritativeness in Assembly Bearing Innovation Through decades of development and research, the field of assembly bearings has seen incredible technological advancements. Leading brands have introduced self-aligning bearings and hybrid designs that incorporate sensors for predictive maintenance, ensuring constant monitoring of machine health. Industry leaders such as SKF and Schaeffler have set standards for innovation in this space, offering solutions that not only solve current mechanical challenges but also anticipate the evolving needs of modern industry. Their focus on research and development has paved the way for innovations like smart bearings, which interact with digital systems and contribute to the burgeoning field of industrial IoT. Trustworthiness and Reliability of Assembly Bearings Procuring assembly bearings from reputable manufacturers ensures high levels of reliability and trust. The quality control processes adopted by these manufacturers guarantee that each bearing meets rigorous standards before it reaches the market. Testimonials from global manufacturers affirm the critical role of quality assurance in selecting assembly bearings. A leading automotive company, for example, reported a significant reduction in warranty claims after switching to bearings from a trusted, certified supplier. Such reliability not only proves essential in maintaining product integrity but also builds consumer trust. In summary, the utilization of assembly bearings embodies a blend of engineering precision, empirical expertise, and innovative foresight. Businesses keen on achieving operational excellence would do well to invest in high-quality assembly bearings, understanding that these components are foundational to the integrity and efficiency of their machinery. By doing so, they not only ensure optimal performance and safety in their operations but also remain at the forefront of technological advancements in their respective industries. Overall, a strategic approach to integrating expertly selected assembly bearings positions companies for sustainable growth and competitive advantage in a rapidly evolving technological landscape.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024