-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 20:19

Back to list

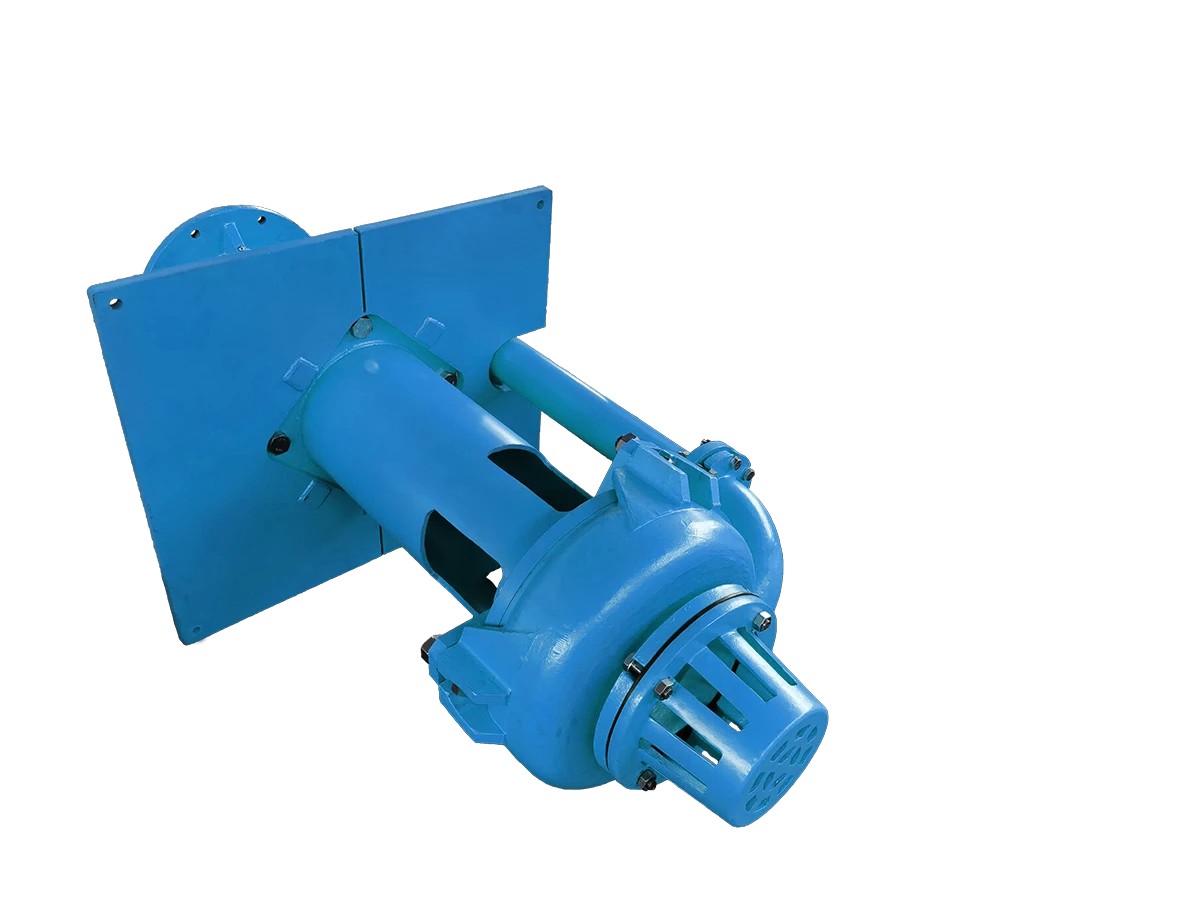

Pump Wear Parts SP20206 Metal

A bearing assembly is a critical component in various mechanical systems, often defining the reliability, efficiency, and lifespan of machinery. While its importance is understood in engineering circles, a more profound insight into its design, function, and application can significantly enhance our understanding and appreciation of this mechanical marvel.

Arguably, the most impressive evolution in bearing assemblies is the integration of smart technologies. Today’s advanced systems often include sensors and IoT capabilities, enabling real-time monitoring of parameters like temperature, vibration, and rotational speed. This data can be analyzed to predict maintenance needs, allowing for proactive rather than reactive service strategies, thus preventing downtime and reducing costs. In today's competitive market, sustainability and efficiency are prevalent concerns. Bearing assemblies address these by optimizing energy consumption through reduced friction and enabling machinery to perform at higher efficiencies. Various industries, from automotive to aerospace, depend on advanced bearing assemblies to push the boundaries of what their machines can do. In automotive applications, for instance, bearings play a crucial role in fuel efficiency and emissions control. In aerospace applications, even the minutest improvement in a bearing assembly's weight or friction characteristics can lead to significant advancements in an aircraft's performance and fuel economy. The expertise required in designing and maintaining bearing assemblies has grown significantly. Engineers, designers, and technicians must be well-versed in the complexities of materials science, dynamics, and tribology. Moreover, they must understand how to interpret data from smart systems and apply preventative maintenance practices to sustain optimal performance levels. Despite the advanced nature of modern bearing assemblies, their fundamental purpose remains unchanged to support and enable motion in machinery reliably and efficiently. Trustworthiness in these components comes from rigorous testing and quality assurance, ensuring that each assembly can withstand the demands of its intended application. This blend of traditional engineering principles and cutting-edge technology makes the bearing assembly an enduringly fascinating topic within mechanical engineering. It's a testament to human ingenuity and the relentless pursuit of perfection in industrial systems. Understanding and appreciating this complexity allows businesses to harness the full potential of their machinery, leading to unprecedented levels of performance and innovation in their respective fields.

Arguably, the most impressive evolution in bearing assemblies is the integration of smart technologies. Today’s advanced systems often include sensors and IoT capabilities, enabling real-time monitoring of parameters like temperature, vibration, and rotational speed. This data can be analyzed to predict maintenance needs, allowing for proactive rather than reactive service strategies, thus preventing downtime and reducing costs. In today's competitive market, sustainability and efficiency are prevalent concerns. Bearing assemblies address these by optimizing energy consumption through reduced friction and enabling machinery to perform at higher efficiencies. Various industries, from automotive to aerospace, depend on advanced bearing assemblies to push the boundaries of what their machines can do. In automotive applications, for instance, bearings play a crucial role in fuel efficiency and emissions control. In aerospace applications, even the minutest improvement in a bearing assembly's weight or friction characteristics can lead to significant advancements in an aircraft's performance and fuel economy. The expertise required in designing and maintaining bearing assemblies has grown significantly. Engineers, designers, and technicians must be well-versed in the complexities of materials science, dynamics, and tribology. Moreover, they must understand how to interpret data from smart systems and apply preventative maintenance practices to sustain optimal performance levels. Despite the advanced nature of modern bearing assemblies, their fundamental purpose remains unchanged to support and enable motion in machinery reliably and efficiently. Trustworthiness in these components comes from rigorous testing and quality assurance, ensuring that each assembly can withstand the demands of its intended application. This blend of traditional engineering principles and cutting-edge technology makes the bearing assembly an enduringly fascinating topic within mechanical engineering. It's a testament to human ingenuity and the relentless pursuit of perfection in industrial systems. Understanding and appreciating this complexity allows businesses to harness the full potential of their machinery, leading to unprecedented levels of performance and innovation in their respective fields.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024