-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 10, 2025 18:29

Back to list

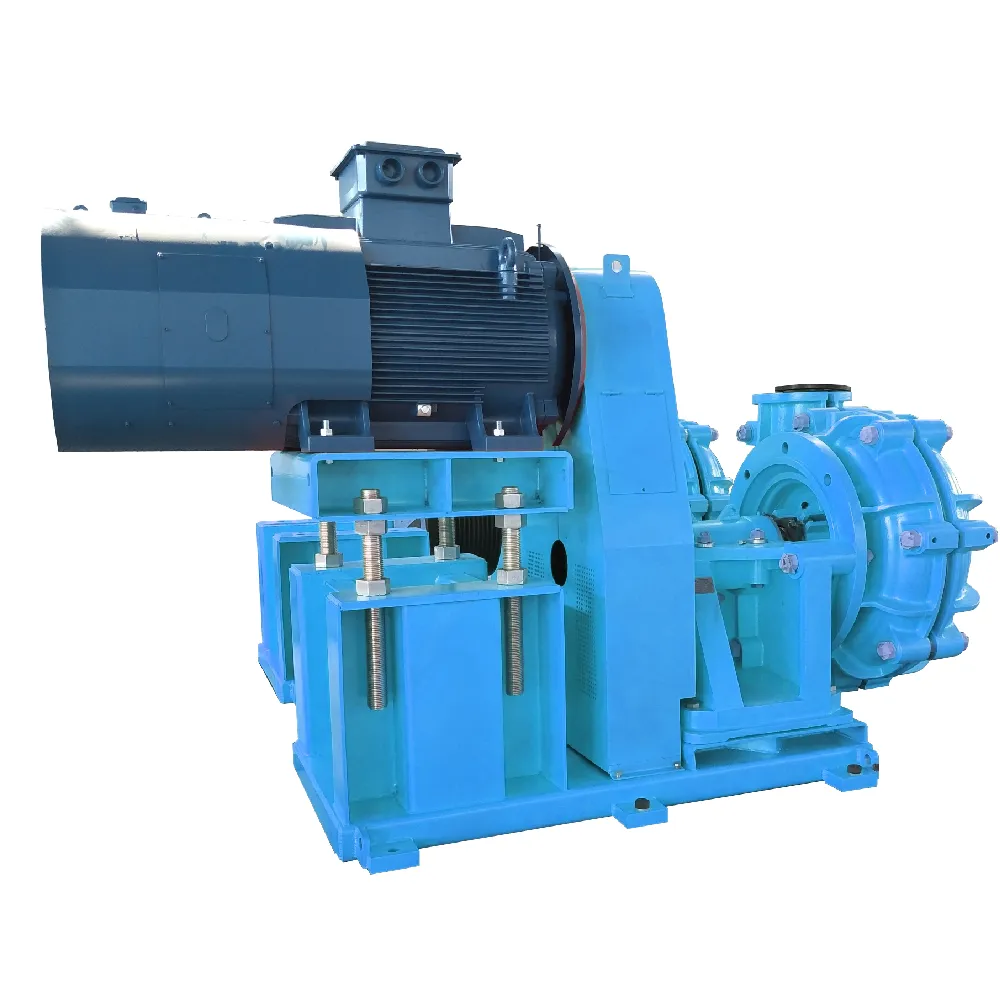

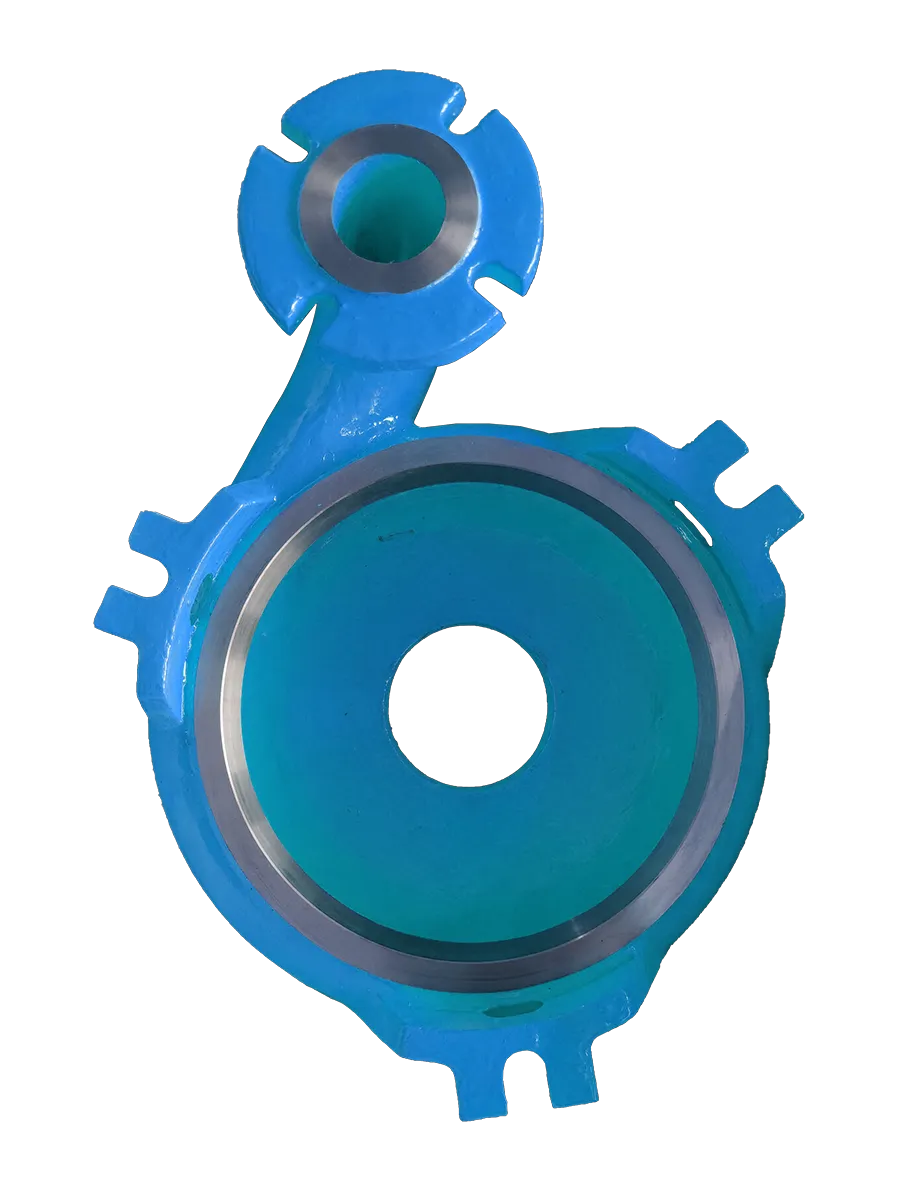

Horizontal Slurry Pumps MM10/8F-AH

Bearing assembly is an intricate process that demands precision, expertise, and attention to detail. Whether you're involved in the automotive, aerospace, industrial, or any field that uses bearings, understanding the nuances of proper bearing assembly is crucial. Proper assembly not only ensures the longevity and efficiency of the bearing but also enhances the performance of the machinery or application it supports.

When placing the bearing into its housing, apply gradual, even pressure. This can often be achieved using a hydraulic press for larger bearings or a soft-faced mallet for smaller ones. It's essential to apply the pressure evenly across the bearing face to prevent misalignment or damage. Never apply pressure directly to the rolling elements, as this can cause immediate failure. After installing the bearing, verify the alignment. Misalignment can reduce the lifespan of the bearing significantly and degrade the performance of the entire application. Use alignment tools and check for smooth, even rotation without any noticeable resistance or binding. Secure the bearing in place, ensuring that retaining mechanisms such as circlips or locking nuts are correctly seated and torqued to the manufacturer's specifications. Over-tightening can deform the bearing or housing, while under-tightening may allow movement and eventual failure. Finally, conduct a test run of the assembled component before full operation. This trial will help identify any issues that might not be visible during assembly. Listen for unusual noises, and feel for excessive vibration or heat, as these can be indicators of improper assembly or installation. Expert assembly of bearings is not only about following a series of steps but about understanding the principles of mechanical operation. The smallest oversight can lead to significant operational disruptions. By adhering to best practices, maintaining a clean working environment, and prioritizing precision, you can ensure efficient and reliable bearing assembly in any application.

When placing the bearing into its housing, apply gradual, even pressure. This can often be achieved using a hydraulic press for larger bearings or a soft-faced mallet for smaller ones. It's essential to apply the pressure evenly across the bearing face to prevent misalignment or damage. Never apply pressure directly to the rolling elements, as this can cause immediate failure. After installing the bearing, verify the alignment. Misalignment can reduce the lifespan of the bearing significantly and degrade the performance of the entire application. Use alignment tools and check for smooth, even rotation without any noticeable resistance or binding. Secure the bearing in place, ensuring that retaining mechanisms such as circlips or locking nuts are correctly seated and torqued to the manufacturer's specifications. Over-tightening can deform the bearing or housing, while under-tightening may allow movement and eventual failure. Finally, conduct a test run of the assembled component before full operation. This trial will help identify any issues that might not be visible during assembly. Listen for unusual noises, and feel for excessive vibration or heat, as these can be indicators of improper assembly or installation. Expert assembly of bearings is not only about following a series of steps but about understanding the principles of mechanical operation. The smallest oversight can lead to significant operational disruptions. By adhering to best practices, maintaining a clean working environment, and prioritizing precision, you can ensure efficient and reliable bearing assembly in any application.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024