-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 02:20

Back to list

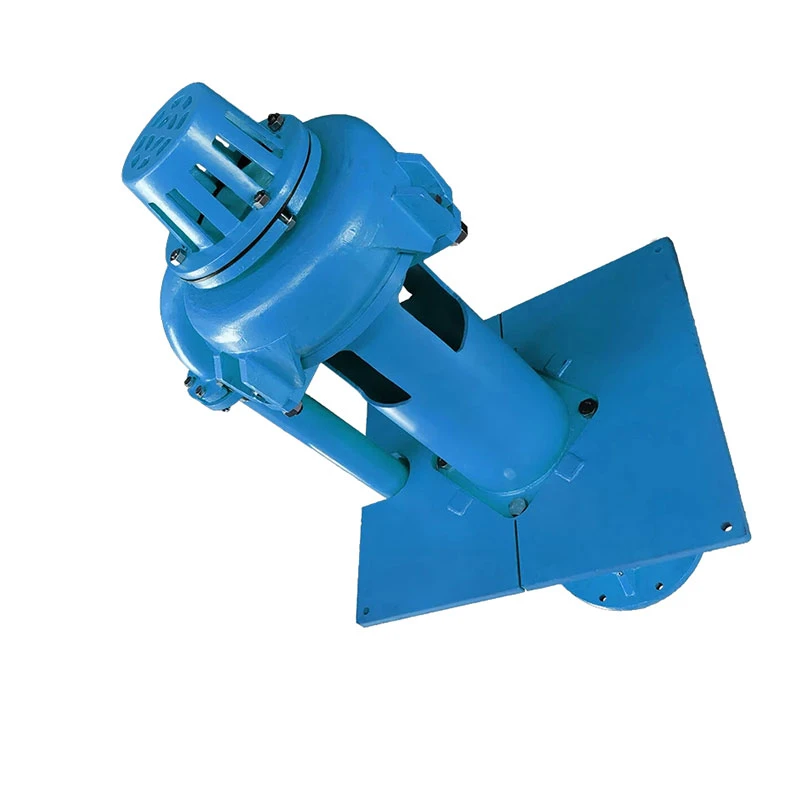

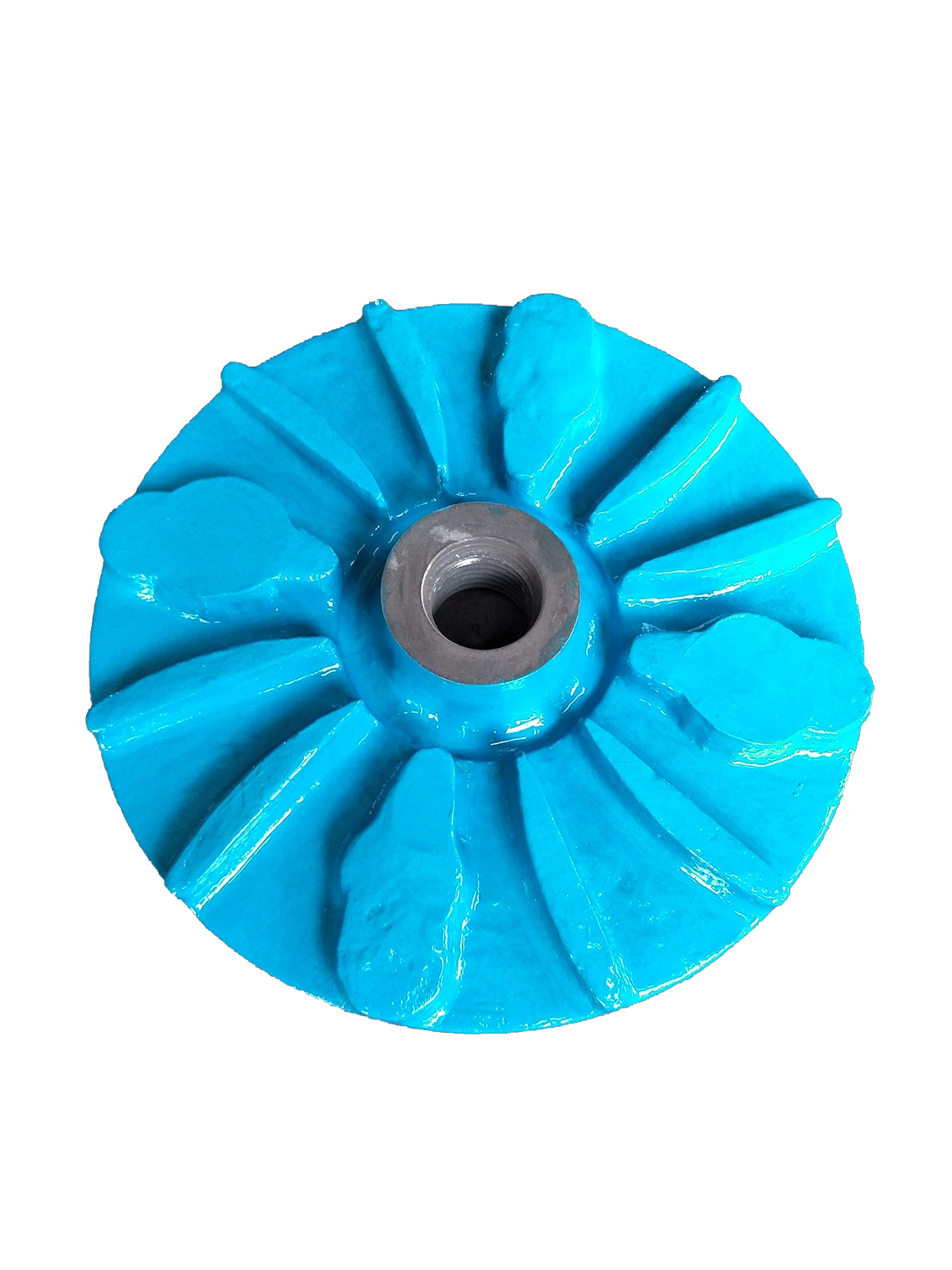

impeller power

Impeller power is an integral aspect of numerous industrial applications. Understanding its nuances can enhance the performance, efficiency, and longevity of equipment dependent on flow dynamics.

Challenges in mastering impeller power involve not only the physical design but also the operational conditions. Users of impeller-driven systems must be mindful of cavitation, a common problem where vapor bubbles form around the impeller due to pressure drops. This phenomenon can cause significant damage to impeller blades, leading to a drastic reduction in power output and system efficiency. Regular monitoring and maintenance, combined with strategic design adjustments, can mitigate these effects. Industry standards and certifications further underscore the importance of precision in impeller power applications. Compliance with organizations such as the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME) ensures that impeller systems are safe, efficient, and reliable. These standards provide a quality benchmark, imbuing an element of trustworthiness in products and solutions. To harness impeller power effectively, manufacturers and users must adopt a holistic approach, one that encompasses expert design, precise engineering, regular maintenance, and adherence to safety standards. Companies that invest in research and development stand at the forefront of innovation, creating impeller solutions that push the boundaries of efficiency and performance. By continually adapting to advancements in technology and materials, as well as maintaining a keen awareness of operational demands, industries reliant on impeller power can achieve significant strides in energy conservation and output efficiency. The role of impeller power in advancing industrial capabilities showcases an interplay of experience, expertise, authoritativeness, and trustworthiness—a stable foundation for sustainable growth and technological evolution.

Challenges in mastering impeller power involve not only the physical design but also the operational conditions. Users of impeller-driven systems must be mindful of cavitation, a common problem where vapor bubbles form around the impeller due to pressure drops. This phenomenon can cause significant damage to impeller blades, leading to a drastic reduction in power output and system efficiency. Regular monitoring and maintenance, combined with strategic design adjustments, can mitigate these effects. Industry standards and certifications further underscore the importance of precision in impeller power applications. Compliance with organizations such as the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME) ensures that impeller systems are safe, efficient, and reliable. These standards provide a quality benchmark, imbuing an element of trustworthiness in products and solutions. To harness impeller power effectively, manufacturers and users must adopt a holistic approach, one that encompasses expert design, precise engineering, regular maintenance, and adherence to safety standards. Companies that invest in research and development stand at the forefront of innovation, creating impeller solutions that push the boundaries of efficiency and performance. By continually adapting to advancements in technology and materials, as well as maintaining a keen awareness of operational demands, industries reliant on impeller power can achieve significant strides in energy conservation and output efficiency. The role of impeller power in advancing industrial capabilities showcases an interplay of experience, expertise, authoritativeness, and trustworthiness—a stable foundation for sustainable growth and technological evolution.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024