-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 01:53

Back to list

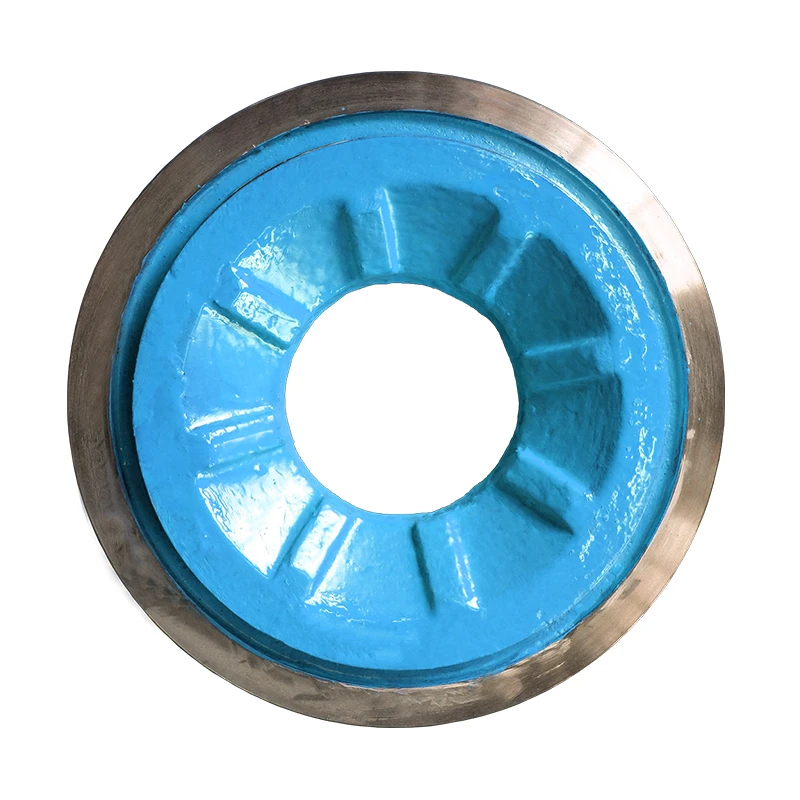

impeller efficiency

Impeller efficiency stands as a pivotal aspect in the realm of fluid dynamics, significantly influencing the performance and operational cost-effectiveness of pumps and turbines. This article delves into the intricacies of impeller efficiency, offering insights gleaned from both hands-on experience and a profound understanding of the subject.

Surface finish and coating are additional factors that significantly impact impeller efficiency. A smoother surface reduces friction between the impeller and the fluid, thus enhancing the flow dynamics and reducing energy loss. Expertise in material science has led to the development of coatings that not only provide a smoother surface but also add protective layers against abrasion and chemical damage. The operational context of the impeller also affects its efficiency. Understanding the specific application, such as the type of fluid being pumped and the operational pressure and temperature conditions, can greatly influence impeller design and selection. Customized solutions, tailored to specific industrial needs, are often necessary. Experts in the field conduct detailed analyses and simulations to ensure that the chosen impeller design meets the designated application's precise requirements, maximizing efficiency and reliability. Manufacturer recommendations and field-based performance assessments yield valuable insights into impeller efficiency. Real-world testing and monitoring help in identifying performance discrepancies and areas for improvement. This hands-on approach, coupled with expert analysis, reinforces the trustworthiness of efficiency claims and aids in the continuous improvement of impeller technology. The integration of smart technologies and IoT has also marked a new era in monitoring impeller efficiency. Sensors provide real-time data on performance metrics, facilitating predictive maintenance and operational optimization. By leveraging data analytics, operators can make informed decisions that enhance system efficiency and decrease downtime. In summation, impeller efficiency is a multifaceted aspect of fluid system performance. It necessitates a blend of expert design, material science, and operational insights to achieve optimal efficiency. Continuous advancements and innovations in technology and methodology underscore the dynamic nature of this field, emphasizing the importance of staying abreast of new developments to maintain competitiveness and operational excellence. This comprehensive understanding, drawn from extensive experience and expert analysis, positions impeller efficiency as a critical driver in the quest for sustainable and efficient hydraulic systems.

Surface finish and coating are additional factors that significantly impact impeller efficiency. A smoother surface reduces friction between the impeller and the fluid, thus enhancing the flow dynamics and reducing energy loss. Expertise in material science has led to the development of coatings that not only provide a smoother surface but also add protective layers against abrasion and chemical damage. The operational context of the impeller also affects its efficiency. Understanding the specific application, such as the type of fluid being pumped and the operational pressure and temperature conditions, can greatly influence impeller design and selection. Customized solutions, tailored to specific industrial needs, are often necessary. Experts in the field conduct detailed analyses and simulations to ensure that the chosen impeller design meets the designated application's precise requirements, maximizing efficiency and reliability. Manufacturer recommendations and field-based performance assessments yield valuable insights into impeller efficiency. Real-world testing and monitoring help in identifying performance discrepancies and areas for improvement. This hands-on approach, coupled with expert analysis, reinforces the trustworthiness of efficiency claims and aids in the continuous improvement of impeller technology. The integration of smart technologies and IoT has also marked a new era in monitoring impeller efficiency. Sensors provide real-time data on performance metrics, facilitating predictive maintenance and operational optimization. By leveraging data analytics, operators can make informed decisions that enhance system efficiency and decrease downtime. In summation, impeller efficiency is a multifaceted aspect of fluid system performance. It necessitates a blend of expert design, material science, and operational insights to achieve optimal efficiency. Continuous advancements and innovations in technology and methodology underscore the dynamic nature of this field, emphasizing the importance of staying abreast of new developments to maintain competitiveness and operational excellence. This comprehensive understanding, drawn from extensive experience and expert analysis, positions impeller efficiency as a critical driver in the quest for sustainable and efficient hydraulic systems.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024