-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 01:35

Back to list

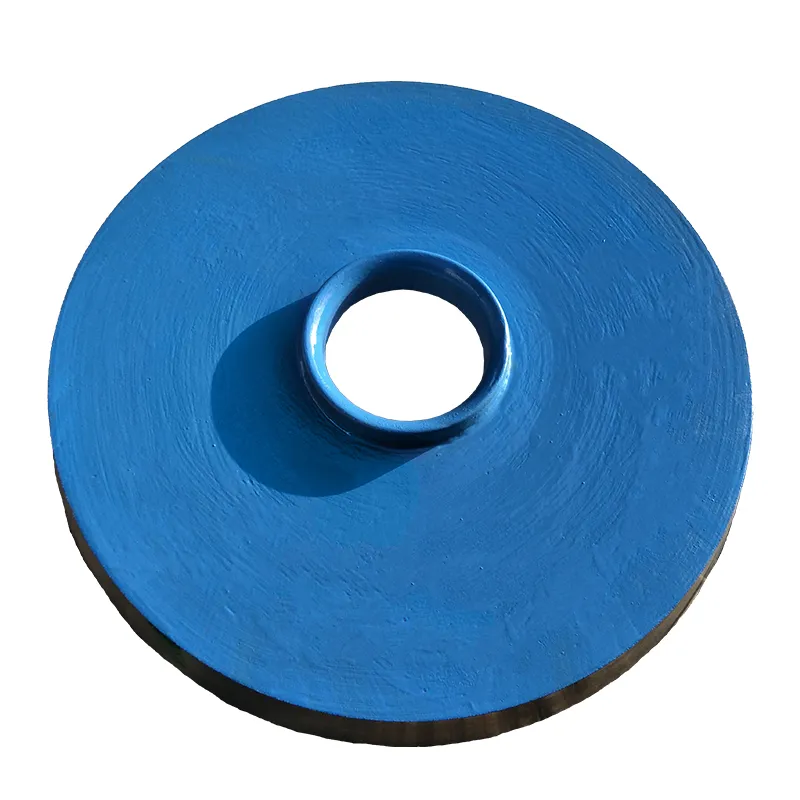

centrifugal pump impeller replacement

Centrifugal pumps are integral to various industries, providing the pressure and flow required for countless applications. However, one of the most critical maintenance tasks involves replacing the impeller, which is the heart of the centrifugal pump. When an impeller becomes worn or damaged, it can drastically affect the pump's performance, leading to decreased efficiency and potential failure. This guide offers a comprehensive examination of centrifugal pump impeller replacement, drawing on years of industry expertise and practical insights to ensure optimal pump performance.

4. Install the New Impeller Align the new impeller onto the pump shaft. Ensure it is securely fastened, using torque specifications provided by the pump manufacturer to avoid over-tightening. 5. Reassemble and Test Replace the pump casing and secure it with bolts. Once reassembled, slowly reconnect power and begin testing to ensure the pump is operational. Check for leaks and monitor vibration levels. Factors When Choosing a Replacement Impeller Material The choice of material can greatly impact the durability of the impeller. Common materials include stainless steel, cast iron, and bronze. The operational environment will often dictate the best material choice in terms of corrosion and wear resistance. Design Ensure that the impeller design matches the operational demands of your system. This includes considerations for size, number of vanes, and vane angles to maximize efficiency. Supplier Credibility Choosing a reputable supplier ensures product quality and adherence to international standards. This builds trust, as the reliability of a high-quality component reduces the risk of frequent replacements. Common Pitfalls and How to Avoid Them One common mistake is selecting an impeller that doesn't match the pump specifications, leading to operational inefficiencies or mechanical failures. Always cross-reference the pump model and the impeller specifications. Another pitfall is improper installation. Even a well-matched impeller can perform poorly if not installed correctly. Engaging with professional services for installation or referring to detailed manufacturer guidelines is advisable. Impeller replacement is a critical maintenance task that requires attention to detail and technical know-how. Adhering to the guidelines provided in this article will not only enhance pump performance but also extend its service life, ensuring efficiency and reliability in your industrial operations. By understanding the nuances of impeller selection and installation, businesses can foster a more robust maintenance culture, thereby safeguarding their investment in pumping systems.

4. Install the New Impeller Align the new impeller onto the pump shaft. Ensure it is securely fastened, using torque specifications provided by the pump manufacturer to avoid over-tightening. 5. Reassemble and Test Replace the pump casing and secure it with bolts. Once reassembled, slowly reconnect power and begin testing to ensure the pump is operational. Check for leaks and monitor vibration levels. Factors When Choosing a Replacement Impeller Material The choice of material can greatly impact the durability of the impeller. Common materials include stainless steel, cast iron, and bronze. The operational environment will often dictate the best material choice in terms of corrosion and wear resistance. Design Ensure that the impeller design matches the operational demands of your system. This includes considerations for size, number of vanes, and vane angles to maximize efficiency. Supplier Credibility Choosing a reputable supplier ensures product quality and adherence to international standards. This builds trust, as the reliability of a high-quality component reduces the risk of frequent replacements. Common Pitfalls and How to Avoid Them One common mistake is selecting an impeller that doesn't match the pump specifications, leading to operational inefficiencies or mechanical failures. Always cross-reference the pump model and the impeller specifications. Another pitfall is improper installation. Even a well-matched impeller can perform poorly if not installed correctly. Engaging with professional services for installation or referring to detailed manufacturer guidelines is advisable. Impeller replacement is a critical maintenance task that requires attention to detail and technical know-how. Adhering to the guidelines provided in this article will not only enhance pump performance but also extend its service life, ensuring efficiency and reliability in your industrial operations. By understanding the nuances of impeller selection and installation, businesses can foster a more robust maintenance culture, thereby safeguarding their investment in pumping systems.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024