-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 02:43

Back to list

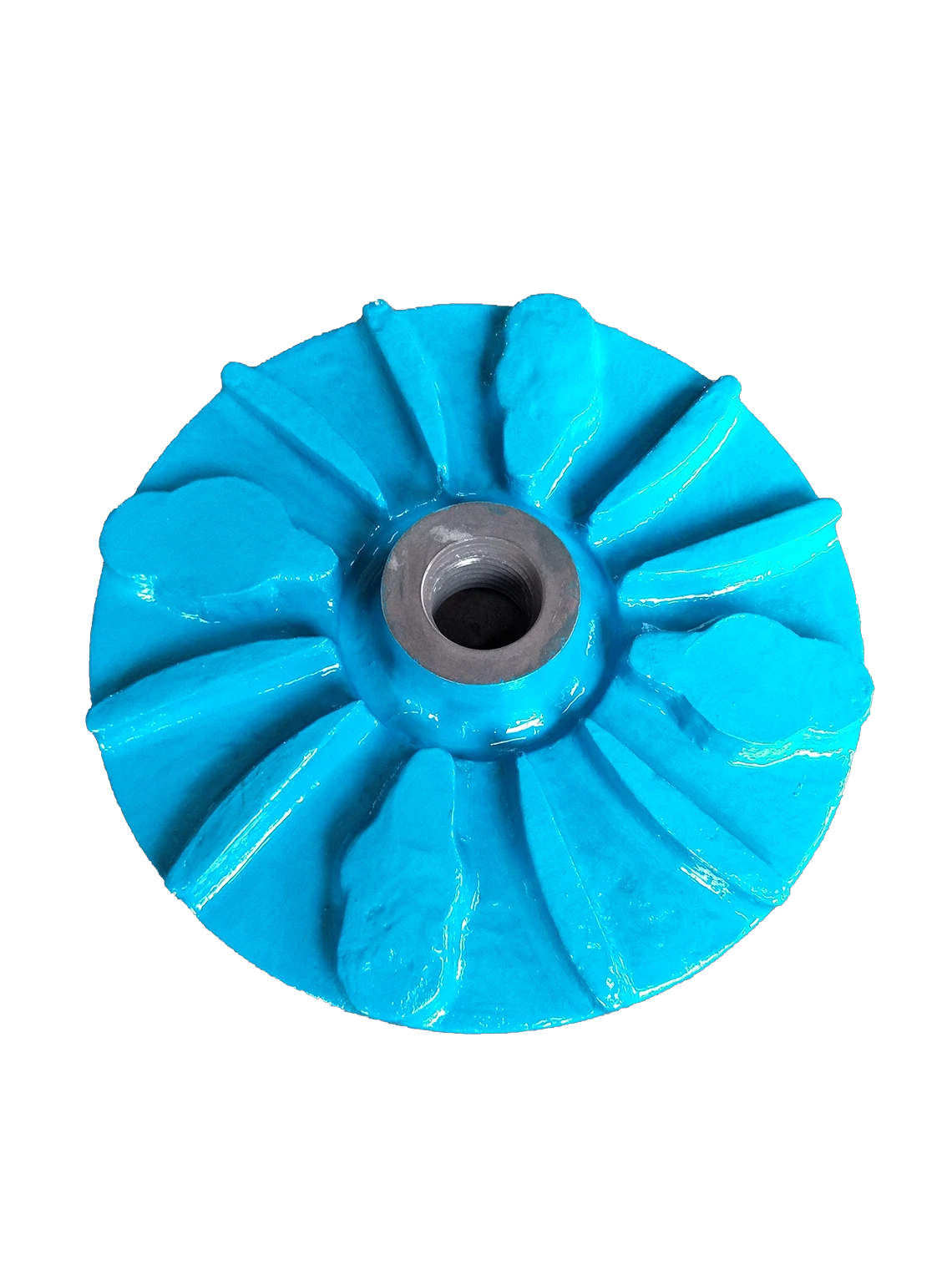

impeller open

An open impeller, often underestimated in its application, is a pivotal component in various industrial and commercial processes. At its core, the open impeller consists of vanes attached to a central hub, with spaces in between that are exposed to the medium being processed. This design inherently offers a unique set of advantages that cater to specific operational requirements, demonstrating exemplary adaptability and efficiency across numerous industries.

The adaptability of open impellers extends to their material composition as well. They can be manufactured from a wide range of materials, including stainless steel and high-performance alloys, which enhances their utility in corrosive environments. This adaptability ensures that open impellers can be custom-tailored to meet rigorous industrial standards, thereby extending their service life even under the most demanding conditions. In terms of expertise, employing open impellers requires an understanding of the specific operational environment and the material characteristics of the fluids being pumped. Expertise in selecting the right impeller material and design can significantly enhance performance and efficiency. For companies navigating complex fluid dynamics, partnering with specialists in pump technology can optimize the deployment of open impellers, ensuring alignment with the operational objectives while adhering to industry safety and efficiency standards. Authoritativeness and trustworthiness in the context of open impellers are established through decades of proven performance in diverse applications. Industry giants producing open impellers adhere to strict manufacturing protocols and conduct extensive testing to ensure that each impeller meets or exceeds performance expectations. Documentation and user testimonials further reinforce their reliability, offering potential users a data-backed foundation upon which to base their operational decisions. In conclusion, while the design of open impellers may seem simplistic, the benefits they deliver in terms of versatility, ease of maintenance, and performance are profound. For industries seeking reliable, efficient, and cost-effective solutions for managing challenging fluid dynamics, open impellers offer a compelling case. Their ability to adapt to various fluids and operational contexts underscores their integral role in modern industrial applications, making them an indispensable component in achieving optimal process efficiency and reliability.

The adaptability of open impellers extends to their material composition as well. They can be manufactured from a wide range of materials, including stainless steel and high-performance alloys, which enhances their utility in corrosive environments. This adaptability ensures that open impellers can be custom-tailored to meet rigorous industrial standards, thereby extending their service life even under the most demanding conditions. In terms of expertise, employing open impellers requires an understanding of the specific operational environment and the material characteristics of the fluids being pumped. Expertise in selecting the right impeller material and design can significantly enhance performance and efficiency. For companies navigating complex fluid dynamics, partnering with specialists in pump technology can optimize the deployment of open impellers, ensuring alignment with the operational objectives while adhering to industry safety and efficiency standards. Authoritativeness and trustworthiness in the context of open impellers are established through decades of proven performance in diverse applications. Industry giants producing open impellers adhere to strict manufacturing protocols and conduct extensive testing to ensure that each impeller meets or exceeds performance expectations. Documentation and user testimonials further reinforce their reliability, offering potential users a data-backed foundation upon which to base their operational decisions. In conclusion, while the design of open impellers may seem simplistic, the benefits they deliver in terms of versatility, ease of maintenance, and performance are profound. For industries seeking reliable, efficient, and cost-effective solutions for managing challenging fluid dynamics, open impellers offer a compelling case. Their ability to adapt to various fluids and operational contexts underscores their integral role in modern industrial applications, making them an indispensable component in achieving optimal process efficiency and reliability.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024