-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

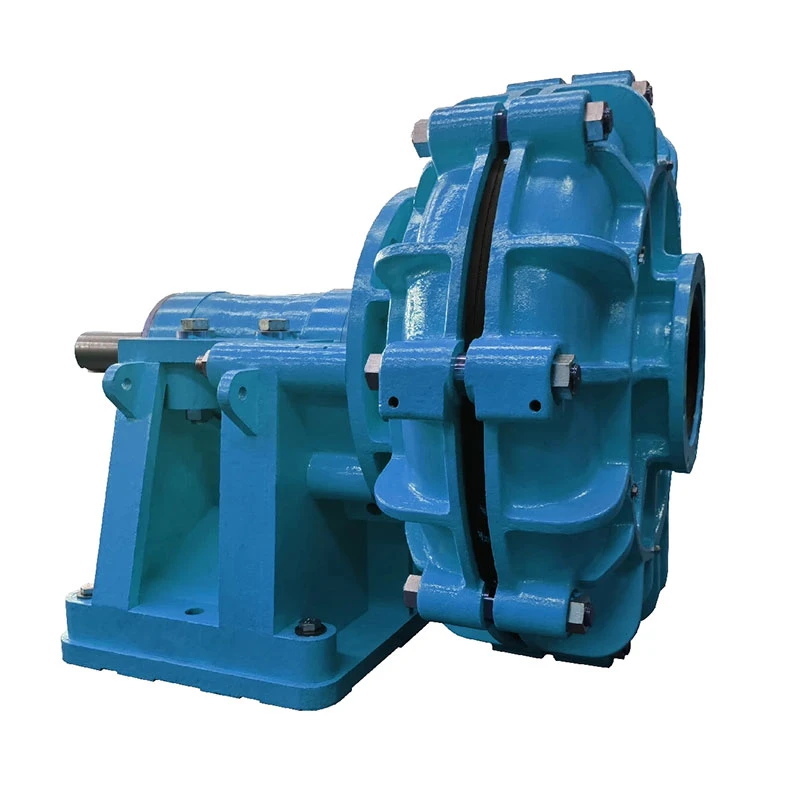

impeller and volute

Understanding Impellers and Volutes in Pump Systems

In the world of fluid mechanics and hydraulic engineering, impellers and volutes play crucial roles in the operation of pumps, particularly centrifugal pumps. These components are essential for converting mechanical energy into hydraulic energy, facilitating the movement of fluids through various systems. Understanding their functionalities and interactions is vital for designing efficient pumping systems.

The Role of Impellers

An impeller is a rotating component of a pump that is responsible for imparting kinetic energy to the fluid. It consists of a series of blades that rotate with the pump shaft. As the impeller spins, it creates a centrifugal force that moves the fluid outward from the center. The design of the impeller, including its size, shape, and number of blades, significantly affects the efficiency and performance of the pump.

There are various designs of impellers, including open, closed, and semi-closed types. Closed impellers, which have shrouds on both sides of the blades, are commonly used for handling liquids with solids, as they provide better performance and efficiency. Open impellers, on the other hand, lack these shrouds and are generally used for applications where the fluid may contain larger solids.

The impeller's performance is often characterized by its flow rate, head (pressure), and efficiency. Efficient impellers can dramatically reduce energy consumption in pumping systems, making them an attractive choice for various industrial applications.

The Function of Volutes

The volute is the part of the pump that surrounds the impeller. It serves the critical function of converting the high-velocity kinetic energy generated by the impeller into pressure energy. As the fluid exits the impeller, it enters the volute, which gradually expands. This expansion causes a decrease in fluid velocity and an increase in pressure, effectively directing the flow of the fluid into the discharge pipe.

impeller and volute

The design of the volute is equally important as it can influence the overall efficiency and performance of the pump. A well-designed volute minimizes energy losses and helps in achieving a uniform flow distribution, which is essential for preventing issues such as cavitation—a phenomenon that occurs when vapor bubbles form in low-pressure areas and can cause damage to the pump.

Volute design involves considerations of geometry, size, and the angle of the discharge. The volute's contour should match the impeller's flow characteristics to ensure optimal energy transfer and minimize turbulence, which can lead to inefficiencies.

The Interaction Between Impellers and Volutes

The interaction between impellers and volutes is a critical factor in determining pump efficiency. An improperly matched impeller and volute can lead to performance issues such as excessive vibration, noise, and reduced lifespan of the pump. Therefore, it is essential for engineers to carefully design and test these components to ensure they work harmoniously together.

Testing and simulation technologies have advanced significantly, allowing for better modeling of fluid dynamics within pumps. Computational Fluid Dynamics (CFD) is often used to analyze and predict the behavior of fluids as they move through the impeller and volute, ensuring that designs are optimized for performance.

Conclusion

In summary, impellers and volutes are indispensable components of centrifugal pumps that play a vital role in fluid transport systems. Their designs greatly influence the overall efficiency, reliability, and performance of pumping systems. As industries continue to evolve and demand more efficient fluid handling solutions, understanding and optimizing the interaction between these two components will remain a key focus for engineers and designers alike. By enhancing the effectiveness of impellers and volutes, we can contribute to energy conservation and improved operational efficiencies across various applications.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024