-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

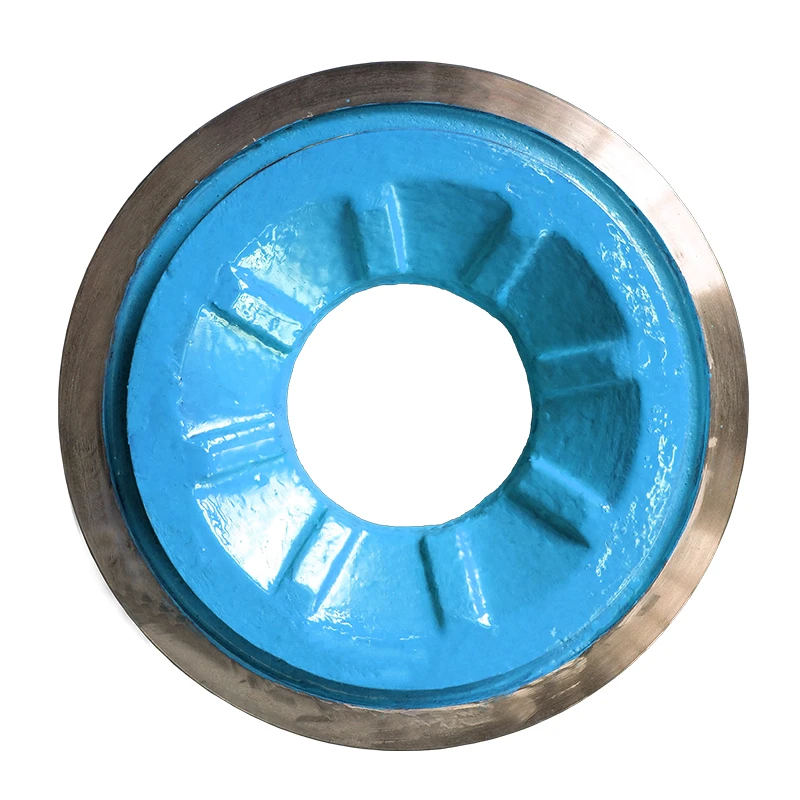

slurry pump impeller suppliers

The Importance of Slurry Pump Impellers and Reliable Suppliers

In various industrial processes, slurry pumps are essential for the efficient transfer of slurries, which are mixtures of solids and liquids. These pumps play a crucial role in industries such as mining, chemical processing, and wastewater treatment, where the transportation of abrasive and viscous materials is a daily operation. An integral component of slurry pumps is the impeller, which is responsible for driving the slurry through the pump system. Therefore, selecting high-quality slurry pump impellers from reputable suppliers is vital for ensuring optimal performance, durability, and efficiency.

Understanding the Function of Slurry Pump Impellers

The primary function of an impeller in a slurry pump is to impart kinetic energy to the slurry, enabling it to flow through the pump and into piping systems. The design of the impeller can significantly affect the pump's efficiency and operational capabilities. Impellers are typically engineered to handle specific types of slurries, including those containing abrasive solids known to cause wear and tear on pump components. A well-designed impeller not only improves the pump's efficiency but also extends its service life by minimizing wear and reducing the frequency of repairs.

Characteristics of Quality Impellers

Quality slurry pump impellers are characterized by their robust construction, materials resistance to corrosion, and adherence to specific design parameters for different slurry types. Typical materials used for impeller manufacturing include high-chrome alloys, rubber-lined materials, and various composites, which provide the necessary strength and durability. Moreover, the impeller shape, size, and configuration can be tailored to meet the requirements of various industrial applications, supporting different slurry flow rates and ensuring maximum efficiency.

Choosing the Right Supplier

When searching for slurry pump impeller suppliers, it is essential to conduct thorough research to find reliable partners. A respected supplier should have a proven track record of producing high-quality products and providing excellent customer service. Here are some considerations to keep in mind when evaluating potential suppliers

slurry pump impeller suppliers

1. Experience and Reputation Look for suppliers with a long history in the slurry pump industry. A strong reputation is often built through consistent product quality and customer satisfaction.

2. Product Range A comprehensive product range indicates the supplier's capability to cater to diverse industrial needs. It’s beneficial to find a supplier that offers various impeller designs and materials.

3. Customization Options Every industrial application is unique, and the ability to customize impellers to fit specific requirements is an essential feature of a good supplier.

4. Quality Assurance Ensure that the supplier adheres to international quality standards. Certifications and industry compliance can serve as indicators of product reliability.

5. Technical Support A supplier that provides technical support and guidance can be invaluable. This includes assistance with installation, troubleshooting, and maintenance of slurry pumps and impellers.

6. Customer Reviews and Testimonials Researching customer experiences can provide insights into the reliability of the supplier and the performance of their products.

Conclusion

In summary, slurry pump impellers are critical components that significantly influence the efficiency and longevity of slurry pumping systems. Selecting high-quality impellers from reputable suppliers is paramount to ensuring optimal performance and durability in industrial applications. By considering factors such as experience, product range, customization capabilities, and quality assurance when choosing a supplier, industries can secure reliable partnerships that contribute to their operational success. Investing time in research and ensuring the right selection will ultimately lead to enhanced productivity and reduced operational costs.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024