-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

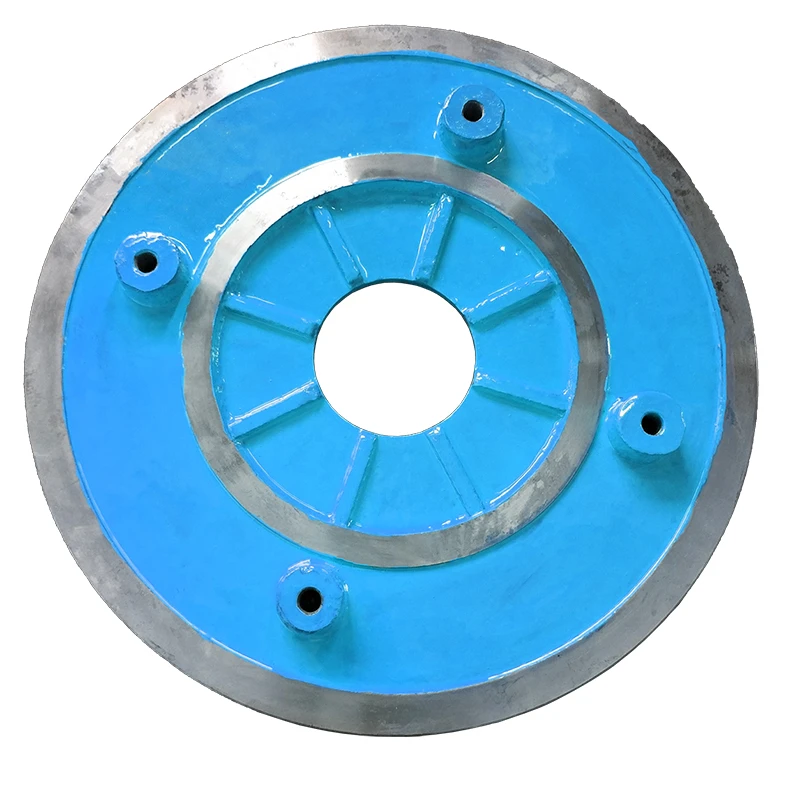

slurry agitator pump

Understanding Slurry Agitator Pumps A Comprehensive Overview

In various industrial applications, the management and transportation of slurries—a mixture of solids and liquids—pose significant challenges. To address these challenges, slurry agitator pumps have emerged as a vital solution. These specialized pumps are designed to handle abrasive, viscous, and often corrosive mixtures, making them indispensable in sectors such as mining, wastewater treatment, and construction.

What is a Slurry Agitator Pump?

A slurry agitator pump is a type of pump specifically engineered to manage slurries. Slurries can consist of materials such as sand, clay, coal, cement, and other particulate matter combined with water or other liquids. The primary function of an agitator pump is to keep these solids suspended and to transport them through pipelines or to various processes without settling, which could cause blockages and malfunctions in the system.

Key Features of Slurry Agitator Pumps

Several features distinguish slurry agitator pumps from other types of pumps

1. Robust Construction Given that slurry applications often involve abrasive materials, these pumps are typically constructed from high-strength alloys, ceramics, or rubber materials that provide durability and resistance to wear.

2. Agitation Mechanism Many slurry pumps are equipped with an agitator mechanism. This may include a set of blades or other agitation devices to stir the slurry, ensuring solid particles remain suspended. This is critical for efficient pumping, as settled solids can lead to pump failure or inefficiencies.

3. Variability in Design Slurry pumps come in various designs—including centrifugal and positive displacement types—to suit different process requirements. Centrifugal slurry pumps are common for high flow rates, while positive displacement pumps are favored for handling slurries with high viscosity or those requiring higher pressure.

4. Adaptability Slurry agitator pumps can be customized to meet specific operational needs. This includes modifications in size, material, and the type of drive mechanism, such as electric or hydraulic systems.

Applications

Slurry agitator pumps find applications across several industries

slurry agitator pump

- Mining One of the primary sectors utilizing slurry pumps, where they transport mixtures of water and minerals, including ores and tailings, from extraction sites to processing facilities.

- Wastewater Treatment In municipal and industrial wastewater treatment plants, these pumps help transport sludge and other waste materials, ensuring effective processing and treatment.

- Construction In construction projects, particularly those involving concrete, slurry pumps play a vital role in transporting cement mixtures and managing excess water.

- Chemical Processing Slurry pumps are also used in the chemical industry, where they handle corrosive materials safely, ensuring a consistent flow and minimizing downtime.

Advantages of Using Slurry Agitator Pumps

Utilizing slurry agitator pumps offers numerous advantages

1. Efficiency By keeping solids suspended, these pumps ensure a continuous flow, reducing the likelihood of clogs and resulting downtime for maintenance.

2. Longevity The robust construction and materials used in slurry pumps enhance their service life, even under harsh operating conditions. This durability translates to lower operational costs over time.

3. Versatility Slurry agitator pumps can handle various types of slurries, making them suitable for diverse applications across multiple industries.

4. Improved Safety The reliable design of slurry pumps minimizes the risk of spills and leakages, promoting a safer working environment.

Conclusion

In conclusion, slurry agitator pumps are essential tools in numerous industrial applications where efficient transport and management of slurries are required. Their robust construction, specialized designs, and effective solids suspension mechanisms make them indispensable in processes ranging from mining to wastewater treatment. As industries continue to evolve and demand for efficient slurry handling grows, the importance of understanding and implementing slurry agitator pumps will only increase. By investing in high-quality slurry pumps, businesses can improve operational efficiency, reduce maintenance costs, and enhance workplace safety, paving the way for more sustainable and productive industrial practices.

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024