-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 25, 2025 03:38

Back to list

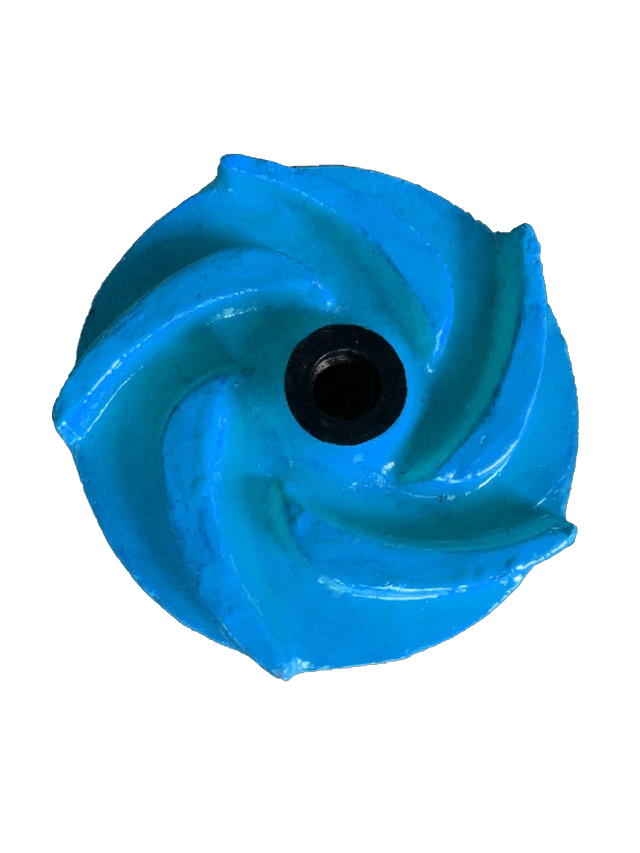

4 inch slurry pump

The 4 inch slurry pump is a critical component in various industrial applications, playing a pivotal role in moving solid-laden fluids efficiently. Primarily utilized in mining, construction, and wastewater management industries, these pumps are designed to handle abrasive and corrosive materials. Their construction involves robust materials that ensure longevity and optimal performance even under challenging conditions.

Trustworthiness is established through compliance with international standards and manufacturing precision. For a product to be considered reliable, it must meet or exceed the standards set by organizations such as the Hydraulic Institute (HI) or the American National Standards Institute (ANSI). Additionally, manufacturers that employ high-grade materials, advanced production techniques, and stringent quality control measures often produce pumps that users can trust under various operational demands. The operational environment also plays a critical role in the longevity and efficiency of a 4 inch slurry pump. It is essential to consider factors such as the temperature, pH levels, and chemical composition of the slurry. Pumps operating in harsh environments with high temperatures or aggressive chemicals might require additional cooling systems or special coatings to prevent corrosion and overheating, ensuring the reliability of the pump over its service life. The importance of after-sales support and warranty cannot be underestimated when investing in a 4 inch slurry pump. Reputable manufacturers provide extensive support, offering expert guidance in installation, maintenance, and troubleshooting. They also provide comprehensive warranties that reflect the confidence in their products, providing peace of mind to the user. In summary, selecting a 4 inch slurry pump should be a well-considered decision involving an understanding of slurry types, material construction, adherence to industry standards, environmental conditions, and comprehensive after-sales support. With advancements in technology, these pumps continue to evolve, offering enhanced efficiency, durability, and reliability, making them indispensable in a multitude of industrial applications.

Trustworthiness is established through compliance with international standards and manufacturing precision. For a product to be considered reliable, it must meet or exceed the standards set by organizations such as the Hydraulic Institute (HI) or the American National Standards Institute (ANSI). Additionally, manufacturers that employ high-grade materials, advanced production techniques, and stringent quality control measures often produce pumps that users can trust under various operational demands. The operational environment also plays a critical role in the longevity and efficiency of a 4 inch slurry pump. It is essential to consider factors such as the temperature, pH levels, and chemical composition of the slurry. Pumps operating in harsh environments with high temperatures or aggressive chemicals might require additional cooling systems or special coatings to prevent corrosion and overheating, ensuring the reliability of the pump over its service life. The importance of after-sales support and warranty cannot be underestimated when investing in a 4 inch slurry pump. Reputable manufacturers provide extensive support, offering expert guidance in installation, maintenance, and troubleshooting. They also provide comprehensive warranties that reflect the confidence in their products, providing peace of mind to the user. In summary, selecting a 4 inch slurry pump should be a well-considered decision involving an understanding of slurry types, material construction, adherence to industry standards, environmental conditions, and comprehensive after-sales support. With advancements in technology, these pumps continue to evolve, offering enhanced efficiency, durability, and reliability, making them indispensable in a multitude of industrial applications.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024