-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 25, 2025 03:16

Back to list

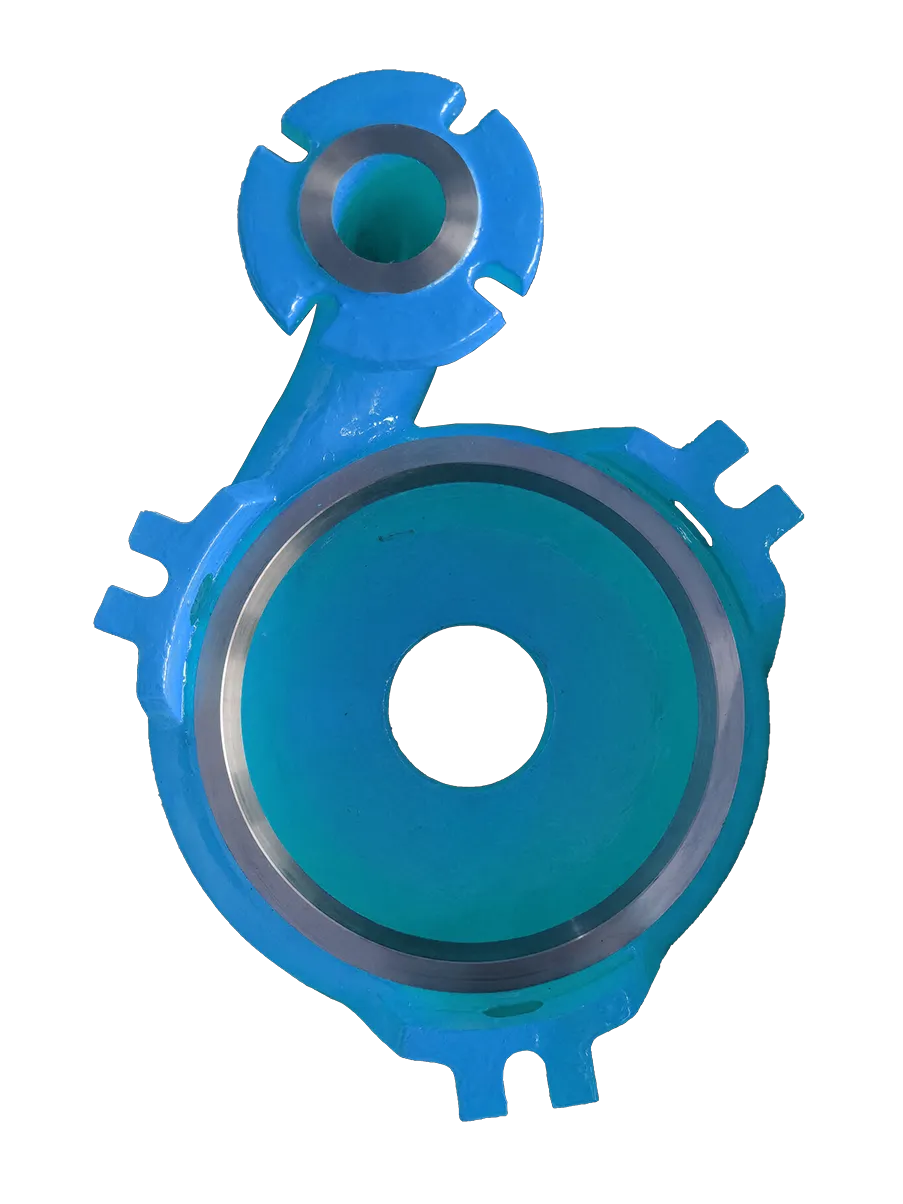

3 inch slurry pump

Selecting the right slurry pump is crucial for many industries where movement of viscous and abrasive materials like sludge or various slurries is needed effectively. The 3-inch slurry pump stands out as an optimal choice for small to medium-sized operations where reliability and efficiency are paramount.

From an authoritative perspective, manufacturers of the 3-inch slurry pump, especially those with a long-standing history in the industry, provide valuable certifications and detailed guidelines that help companies make informed choices. These manufacturers often lead in innovation, offering models with enhanced features such as improved seal technology to prevent leakage, which is often a common problem with slurry pumps. Such advancements demonstrate their continued commitment to solving industry-specific challenges, building credibility and trust within the market. Trustworthiness is further bolstered by comprehensive after-sales support offered by many leading brands. Companies find reassurance in 24/7 customer service availability, extensive warranty packages, and readily available spare parts. This support network is crucial for ensuring the pump remains functional and efficient throughout its lifecycle, thereby providing peace of mind and a secure investment. In conclusion, the 3-inch slurry pump emerges as an essential tool, prided for its durability, efficiency, and ease of use. Its robust build caters to demanding environments, while its design focuses on maximizing material throughput with minimal maintenance. Ensuring proper selection and maintenance, supported by authoritative guidance from established manufacturers, companies can significantly enhance their operational productivity and reliability. When chosen and maintained correctly, this pump not only promises performance but assures stakeholders of a reliable and long-term investment in their operational infrastructure.

From an authoritative perspective, manufacturers of the 3-inch slurry pump, especially those with a long-standing history in the industry, provide valuable certifications and detailed guidelines that help companies make informed choices. These manufacturers often lead in innovation, offering models with enhanced features such as improved seal technology to prevent leakage, which is often a common problem with slurry pumps. Such advancements demonstrate their continued commitment to solving industry-specific challenges, building credibility and trust within the market. Trustworthiness is further bolstered by comprehensive after-sales support offered by many leading brands. Companies find reassurance in 24/7 customer service availability, extensive warranty packages, and readily available spare parts. This support network is crucial for ensuring the pump remains functional and efficient throughout its lifecycle, thereby providing peace of mind and a secure investment. In conclusion, the 3-inch slurry pump emerges as an essential tool, prided for its durability, efficiency, and ease of use. Its robust build caters to demanding environments, while its design focuses on maximizing material throughput with minimal maintenance. Ensuring proper selection and maintenance, supported by authoritative guidance from established manufacturers, companies can significantly enhance their operational productivity and reliability. When chosen and maintained correctly, this pump not only promises performance but assures stakeholders of a reliable and long-term investment in their operational infrastructure.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024