-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

1 月 . 25, 2025 04:02

Back to list

slurry pump specification

Slurry pumps play an integral role in various industries, acting as the workhorses in transporting a mixture of solid particles suspended in a liquid. When selecting a suitable slurry pump, understanding how specifications affect performance is crucial. This article delves into key elements you should consider, based on real-world experiences and industry expertise, ensuring you choose the most effective pump for your needs.

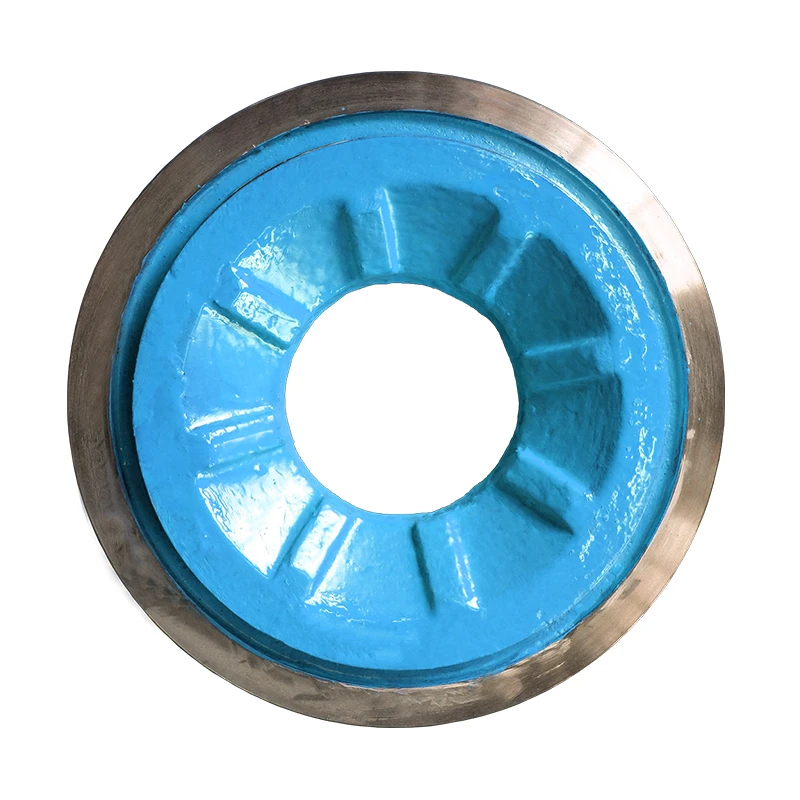

Considering the operational environment is vital, with varying temperatures, pressures, and slurry compositions vastly influencing performance. For applications dealing with extreme temperatures or pressures, selecting pumps with appropriate thermal and pressure ratings is non-negotiable. A chemical processing plant found that pumps with enhanced seals and bearings could withstand elevated temperature fluctuations, maintaining performance stability. Additionally, expert consultations and authority sources emphasize the importance of customizing pump impellers and liners to suit the specific slurry. Standard impellers wear out faster in highly abrasive conditions, whereas specialized designs extend operational lifespan and efficiency. A Nepalese hydroelectric project avoided expensive pump replacements by incorporating customized impeller designs tailored to their specific sediment-laden water conditions. Trustworthiness in selecting slurry pumps comes from relying on brands with proven track records, certified compliance to international standards such as ISO or ANSI, and positive field testing feedback. Many operations affirm enhanced reliability after engaging with reputed manufacturers whose pumps consistently meet and exceed specified performance benchmarks. Understanding these specifications allows not only for selection of the optimal slurry pump but also for maximizing process efficiency, reducing operational costs, and enhancing system longevity. Properly educated decisions based on industry-specific needs minimize downtime and bolster productivity, leading your operations to sustained success and profitability.

Considering the operational environment is vital, with varying temperatures, pressures, and slurry compositions vastly influencing performance. For applications dealing with extreme temperatures or pressures, selecting pumps with appropriate thermal and pressure ratings is non-negotiable. A chemical processing plant found that pumps with enhanced seals and bearings could withstand elevated temperature fluctuations, maintaining performance stability. Additionally, expert consultations and authority sources emphasize the importance of customizing pump impellers and liners to suit the specific slurry. Standard impellers wear out faster in highly abrasive conditions, whereas specialized designs extend operational lifespan and efficiency. A Nepalese hydroelectric project avoided expensive pump replacements by incorporating customized impeller designs tailored to their specific sediment-laden water conditions. Trustworthiness in selecting slurry pumps comes from relying on brands with proven track records, certified compliance to international standards such as ISO or ANSI, and positive field testing feedback. Many operations affirm enhanced reliability after engaging with reputed manufacturers whose pumps consistently meet and exceed specified performance benchmarks. Understanding these specifications allows not only for selection of the optimal slurry pump but also for maximizing process efficiency, reducing operational costs, and enhancing system longevity. Properly educated decisions based on industry-specific needs minimize downtime and bolster productivity, leading your operations to sustained success and profitability.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024