-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 16, 2025 06:59

Back to list

what is a volute in a pump

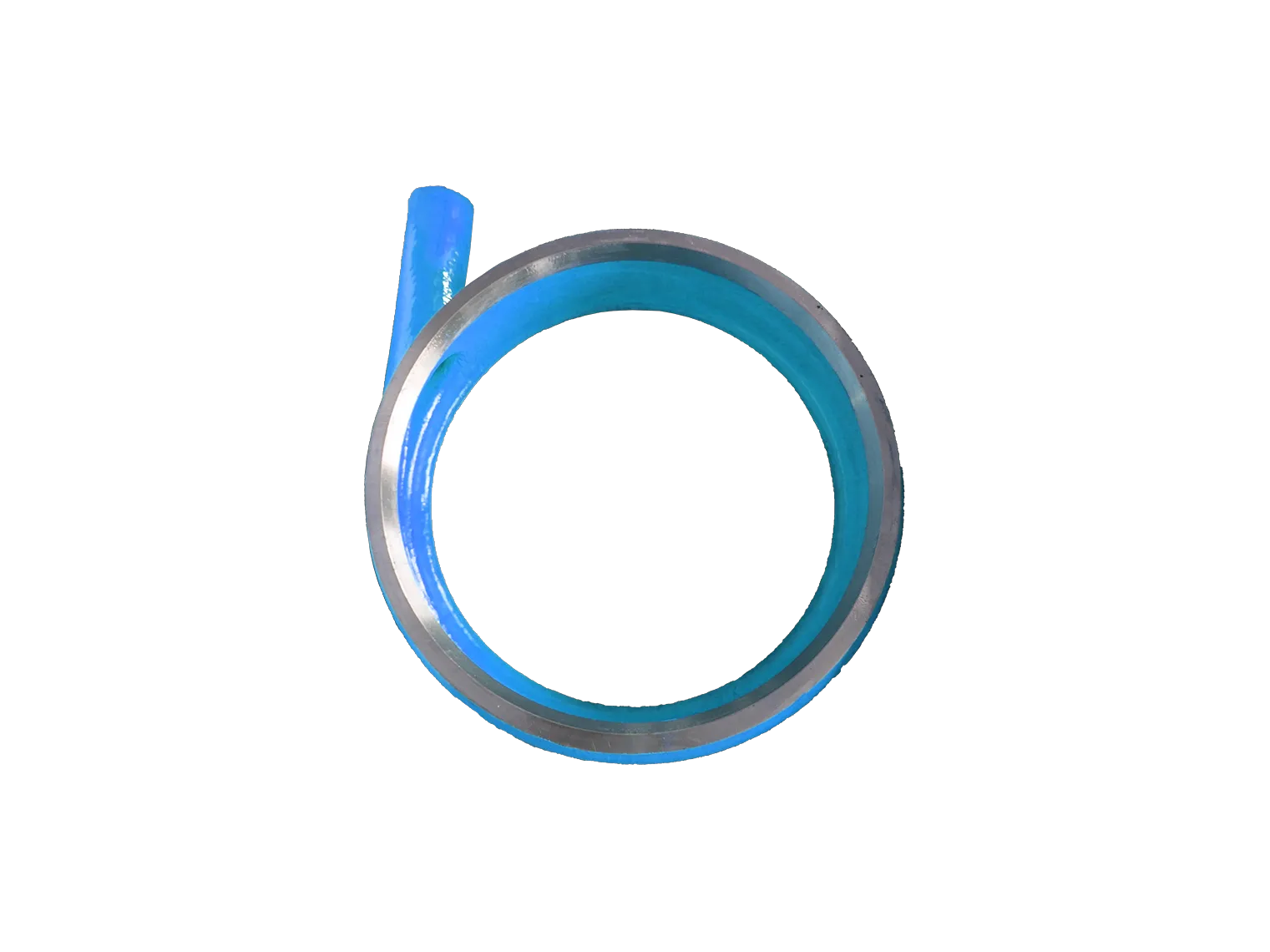

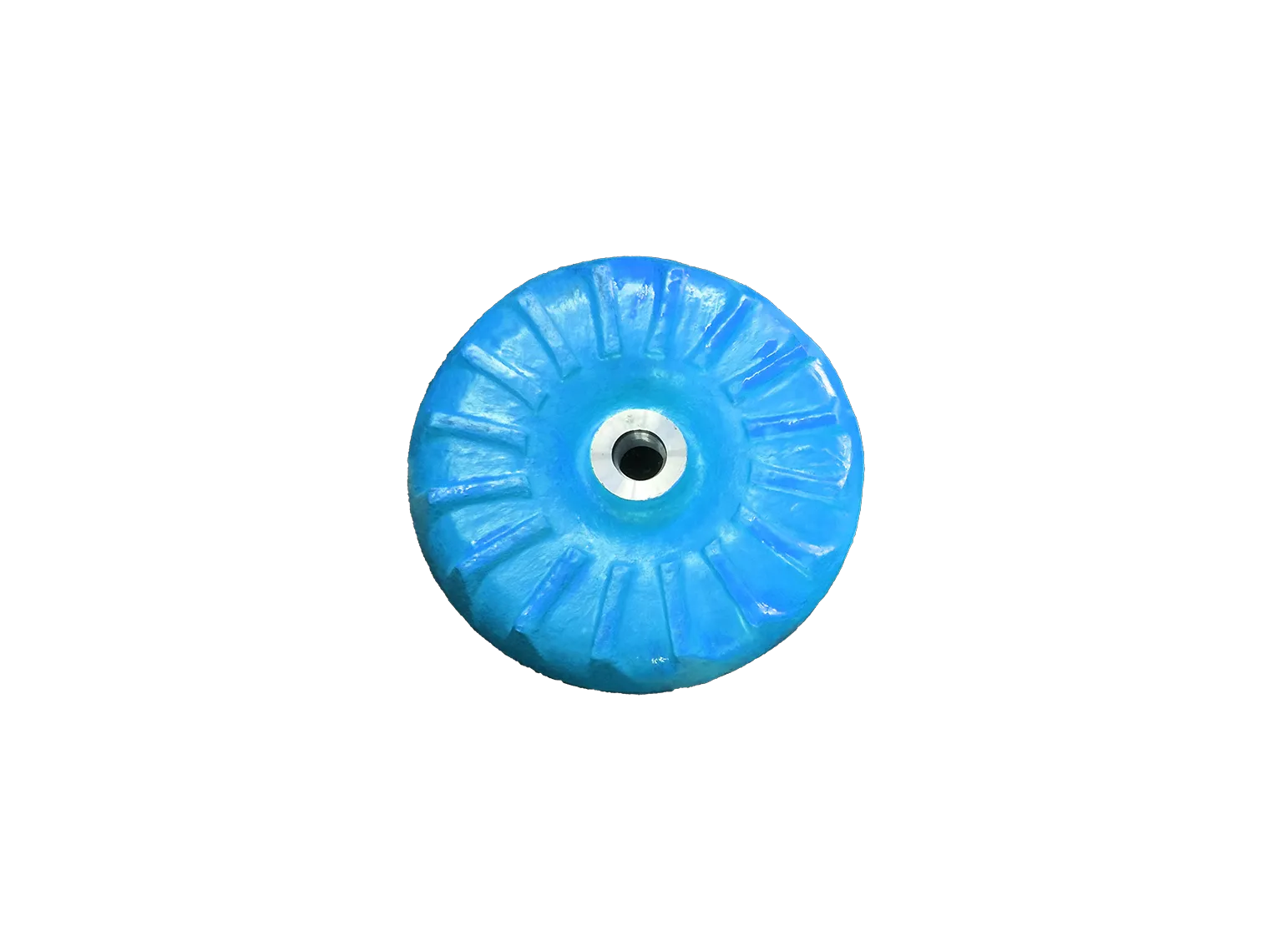

A volute in a pump is a fundamental component designed to convert the kinetic energy of a fluid flow into pressure energy by decreasing the flow velocity and consequently increasing the pressure. Understanding this component's function and design is crucial for anyone involved in the operation or maintenance of centrifugal pumps, where volutes play a key role.

Precise engineering of the volute geometry is paramount. Novel advancements in computational fluid dynamics (CFD) allow for sophisticated modeling before a pump is even built, enabling engineers to simulate flow patterns and optimize volute dimensions for specific fluids and operational conditions. Expert knowledge in CFD simulations facilitates achieving high-efficiency designs, which is critical for reducing energy costs and adhering to stringent environmental regulations. Authoritative guidance from industry standards and pump manufacturers also underscores the significance of regular inspection and maintenance of the volute. Best practices dictate routine checks for wear and tear, especially in applications involving hazardous or corrosive materials. Worn volutes can lead to inefficient operation, leakage, and increased downtime—issues that seasoned experts strive to preempt. Volute retrofitting and customization are advanced topics that further illustrate this component's importance. Retrofitting involves modifying existing volutes to enhance performance or adjust to new operational requirements—one of the many strategies pump specialists use to extend the equipment's functional lifespan without significant capital investment in new systems. These alterations require a deep understanding of fluid dynamics and pump mechanics to ensure enhancements yield the desired benefits. In conclusion, the volute in a pump is more than just a housing for the impeller. It is a critical component whose design, material, and maintenance significantly impact pump efficiency and longevity. Expertise in selecting the appropriate volute design and understanding its operational principles translates into substantial cost savings and improved system reliability. Mastery of this element is quintessential for professionals committed to achieving excellence in fluid handling industries, affirming the vital role of volutes in centrifugal pumps.

Precise engineering of the volute geometry is paramount. Novel advancements in computational fluid dynamics (CFD) allow for sophisticated modeling before a pump is even built, enabling engineers to simulate flow patterns and optimize volute dimensions for specific fluids and operational conditions. Expert knowledge in CFD simulations facilitates achieving high-efficiency designs, which is critical for reducing energy costs and adhering to stringent environmental regulations. Authoritative guidance from industry standards and pump manufacturers also underscores the significance of regular inspection and maintenance of the volute. Best practices dictate routine checks for wear and tear, especially in applications involving hazardous or corrosive materials. Worn volutes can lead to inefficient operation, leakage, and increased downtime—issues that seasoned experts strive to preempt. Volute retrofitting and customization are advanced topics that further illustrate this component's importance. Retrofitting involves modifying existing volutes to enhance performance or adjust to new operational requirements—one of the many strategies pump specialists use to extend the equipment's functional lifespan without significant capital investment in new systems. These alterations require a deep understanding of fluid dynamics and pump mechanics to ensure enhancements yield the desired benefits. In conclusion, the volute in a pump is more than just a housing for the impeller. It is a critical component whose design, material, and maintenance significantly impact pump efficiency and longevity. Expertise in selecting the appropriate volute design and understanding its operational principles translates into substantial cost savings and improved system reliability. Mastery of this element is quintessential for professionals committed to achieving excellence in fluid handling industries, affirming the vital role of volutes in centrifugal pumps.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024