-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 16, 2025 06:41

Back to list

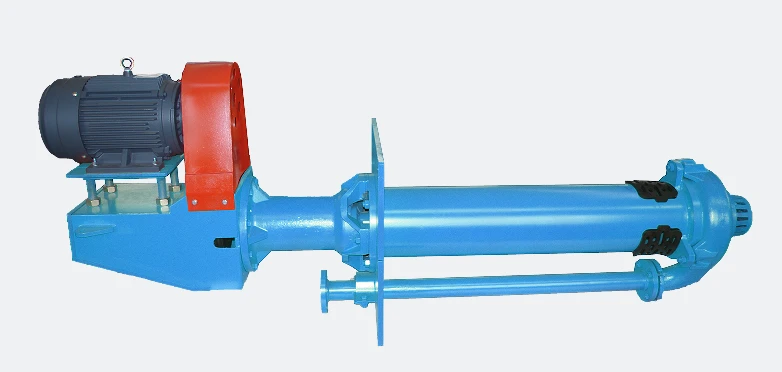

volute pump design

Volute pumps, used in various industrial applications, are indispensable for effective fluid transportation. While the basic principles of volute pump design may appear straightforward, achieving optimal performance, efficiency, and reliability requires a nuanced understanding of both fluid dynamics and materials science. This article delves into these complexities, providing insights born from extensive hands-on experience and thorough expertise in the field.

Real-world performance validation further grounds the theoretical and simulated aspects of volute pump design. Prototyping is an iterative process that tests the pump in actual operating conditions to refine its performance metrics. Extensive field testing can reveal issues not anticipated by simulations alone, such as vibration patterns under varying loads or unusual wear rates. Engineers must thus integrate both simulation data and empirical findings to fine-tune design parameters. In terms of authoritativeness in the field, the ongoing collaboration with industry bodies and adherence to standards such as those set by the Hydraulic Institute or ISO further bolster the reliability of a volute pump design. In particular, compliance with efficiency and safety standards ensures that the pump will perform under set conditions, an assurance both designers and end-users rely on. Investing in these advanced design strategies and technologies speaks not only to expertise but also to trustworthiness. End-users benefit from volute pumps that offer higher efficiency, reduced operational costs, and longer service lives. For businesses, this translates to competitive advantage and enhanced reputation among clients. The dedication to excellence in volute pump design is a testament to a commitment to precision engineering, reliability, and responsibility towards sustainable industrial practices. In conclusion, the art and science of crafting a volute pump involve integrating advanced design techniques, meticulous material selection, and rigorous testing. Manufacturers and engineers with extensive experience deliver higher value and reliability through carefully honed expertise, ensuring these pumps efficiently meet complex industrial demands with authority and trust.

Real-world performance validation further grounds the theoretical and simulated aspects of volute pump design. Prototyping is an iterative process that tests the pump in actual operating conditions to refine its performance metrics. Extensive field testing can reveal issues not anticipated by simulations alone, such as vibration patterns under varying loads or unusual wear rates. Engineers must thus integrate both simulation data and empirical findings to fine-tune design parameters. In terms of authoritativeness in the field, the ongoing collaboration with industry bodies and adherence to standards such as those set by the Hydraulic Institute or ISO further bolster the reliability of a volute pump design. In particular, compliance with efficiency and safety standards ensures that the pump will perform under set conditions, an assurance both designers and end-users rely on. Investing in these advanced design strategies and technologies speaks not only to expertise but also to trustworthiness. End-users benefit from volute pumps that offer higher efficiency, reduced operational costs, and longer service lives. For businesses, this translates to competitive advantage and enhanced reputation among clients. The dedication to excellence in volute pump design is a testament to a commitment to precision engineering, reliability, and responsibility towards sustainable industrial practices. In conclusion, the art and science of crafting a volute pump involve integrating advanced design techniques, meticulous material selection, and rigorous testing. Manufacturers and engineers with extensive experience deliver higher value and reliability through carefully honed expertise, ensuring these pumps efficiently meet complex industrial demands with authority and trust.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024