-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 20, 2025 04:52

Back to list

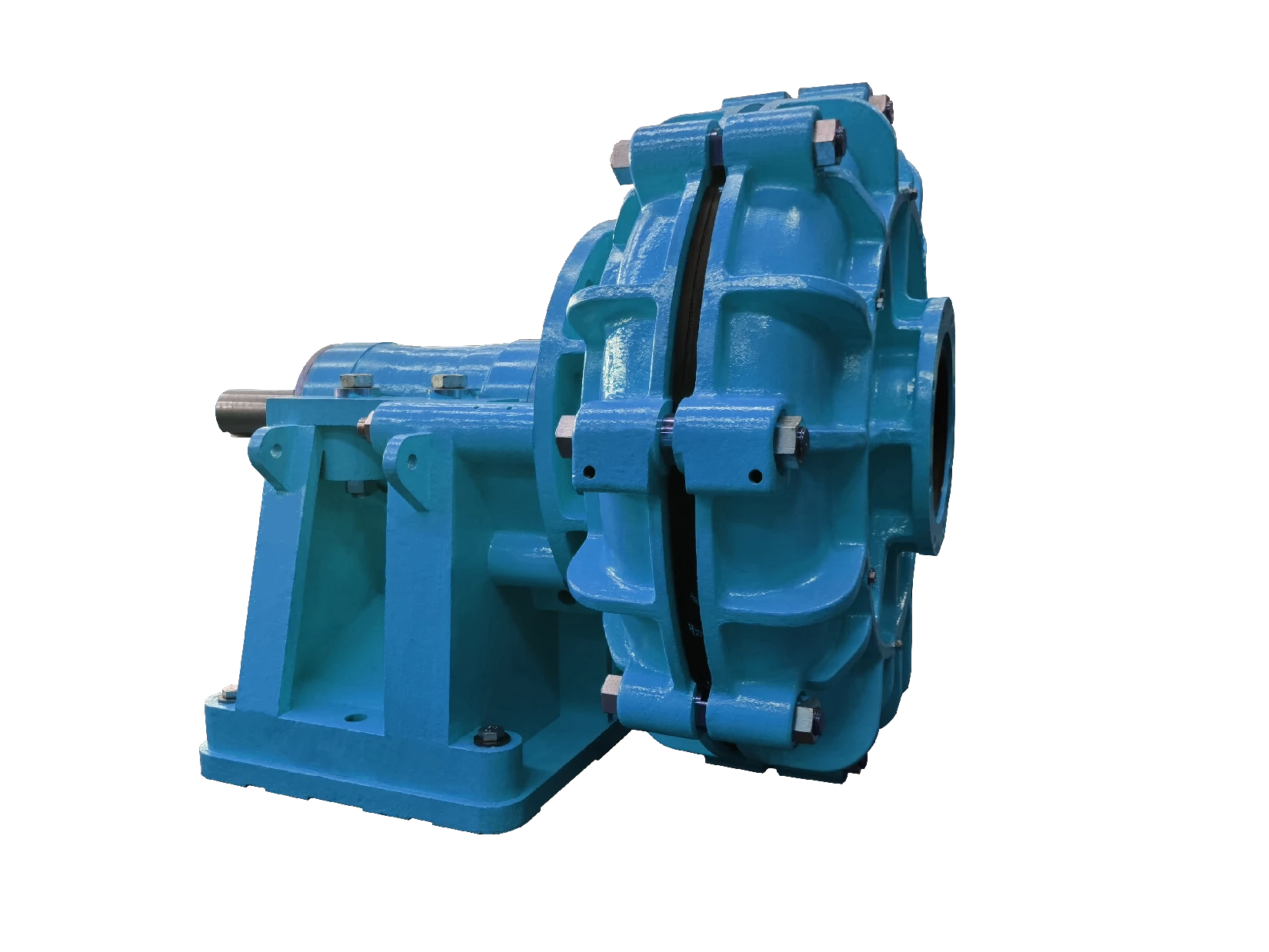

wastewater sludge pumps

Wastewater sludge pumps stand as a cornerstone in the effective management of sludge treatment facilities, serving a critical role in the seamless operation of wastewater processing plants. Delving into the intricate balance between innovation, efficiency, and sustainable solutions, these pumps embody the crucial elements necessary for shifting towards more sustainable operations in waste management.

When it comes to trustworthiness, operators and facility managers rely on pumps that are backed by comprehensive warranties and customer support services. A crucial component of trust in this sector is the availability of after-sales service and an extensive network of service technicians able to handle repairs and maintenance swiftly. Leading companies recognize this need, offering extensive training and technical support, ensuring operators are well-equipped to use their equipment to the fullest potential. Adopting new and advanced wastewater sludge pumps can significantly impact operational efficiency. Operators who have transitioned to these next-gen solutions report reduced maintenance costs, extended equipment lifespan, and improved overall productivity within their facilities. As the industry trends towards digitalization and automation, incorporating these sophisticated pumps represents a proactive step towards achieving higher operational standards. In summation, wastewater sludge pumps have evolved into critical assets within the broader framework of wastewater treatment and management. Their design, underpinned by operational efficiency, regulatory compliance, and technological innovation, makes them an invaluable resource for any treatment facility aiming to improve its operations sustainably. By harnessing their potential, industry leaders can effectively navigate the complexities of modern environmental challenges, leading to cleaner, more efficient wastewater processing environments.

When it comes to trustworthiness, operators and facility managers rely on pumps that are backed by comprehensive warranties and customer support services. A crucial component of trust in this sector is the availability of after-sales service and an extensive network of service technicians able to handle repairs and maintenance swiftly. Leading companies recognize this need, offering extensive training and technical support, ensuring operators are well-equipped to use their equipment to the fullest potential. Adopting new and advanced wastewater sludge pumps can significantly impact operational efficiency. Operators who have transitioned to these next-gen solutions report reduced maintenance costs, extended equipment lifespan, and improved overall productivity within their facilities. As the industry trends towards digitalization and automation, incorporating these sophisticated pumps represents a proactive step towards achieving higher operational standards. In summation, wastewater sludge pumps have evolved into critical assets within the broader framework of wastewater treatment and management. Their design, underpinned by operational efficiency, regulatory compliance, and technological innovation, makes them an invaluable resource for any treatment facility aiming to improve its operations sustainably. By harnessing their potential, industry leaders can effectively navigate the complexities of modern environmental challenges, leading to cleaner, more efficient wastewater processing environments.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024