-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 20, 2025 04:13

Back to list

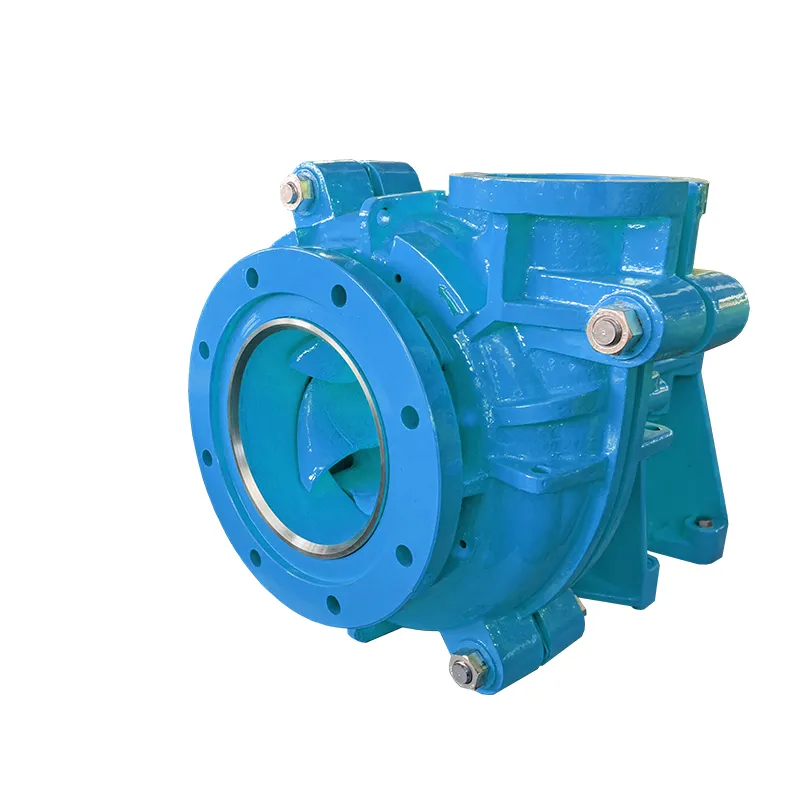

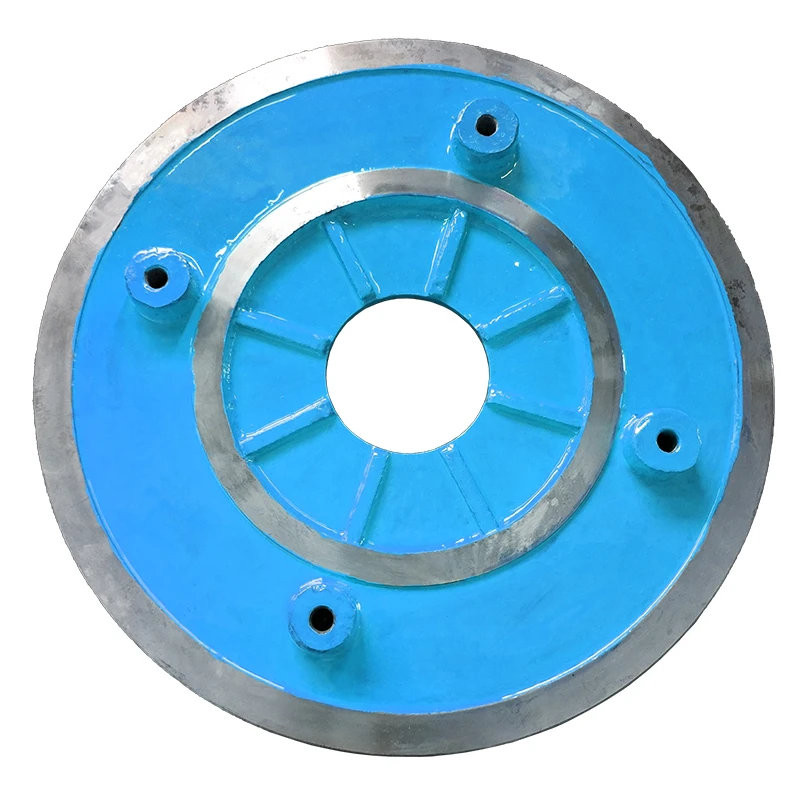

vapor blasting slurry pump

Vapor blasting, an advanced technique used extensively in industries ranging from automotive restoration to aerospace maintenance, requires the use of a reliable slurry pump. A vapor blasting slurry pump is integral to the system's performance, ensuring the optimal delivery of the abrasive-laden liquid to the surface being treated. For those seeking to enhance their understanding and expertise on the subject, here is a comprehensive look into vapor blasting slurry pumps to optimize their applications for high-efficiency operations.

To ensure trustworthiness, manufacturers of vapor blasting slurry pumps often certify their products to relevant industry standards, such as those set by ISO or ASME. Certifications like these provide assurance of the pump's performance and safety characteristics. Knowledge of these certifications is essential for users who wish to guarantee that their equipment not only meets but exceeds industry expectations. Furthermore, experience plays a vital role in the installation and maintenance of vapor blasting slurry pumps. Real-world experience reveals that alignment of the pump within the system, minimizing vibration, and securing reliable power connections directly impact service longevity and performance consistency. Ensuring this equipment operates at peak performance also involves routine inspections to monitor seal integrity, impeller condition, and motor function. Authoritativeness in this domain can be bolstered by engaging with peer-reviewed studies, case studies, and industry reports that validate vapor blasting slurry pump performance. Attending industry conferences and training sessions enhances practical knowledge, keeping professionals informed of the latest innovations and best practices in slurry pump technology. In conclusion, the vapor blasting slurry pump is a specialized piece of equipment that demands a nuanced understanding of its specifications, materials, and energy requirements. Selecting and maintaining the right pump involves a blend of expert knowledge, real-world experience, and authoritative industry insights. By prioritizing these elements, companies can achieve optimal vapor blasting results, driving efficiency and effectiveness in their operations. As industries evolve, keeping abreast of new technologies and developments in slurry pumps will be essential for maintaining a competitive edge, ensuring sustainability, and meeting ever-increasing performance standards.

To ensure trustworthiness, manufacturers of vapor blasting slurry pumps often certify their products to relevant industry standards, such as those set by ISO or ASME. Certifications like these provide assurance of the pump's performance and safety characteristics. Knowledge of these certifications is essential for users who wish to guarantee that their equipment not only meets but exceeds industry expectations. Furthermore, experience plays a vital role in the installation and maintenance of vapor blasting slurry pumps. Real-world experience reveals that alignment of the pump within the system, minimizing vibration, and securing reliable power connections directly impact service longevity and performance consistency. Ensuring this equipment operates at peak performance also involves routine inspections to monitor seal integrity, impeller condition, and motor function. Authoritativeness in this domain can be bolstered by engaging with peer-reviewed studies, case studies, and industry reports that validate vapor blasting slurry pump performance. Attending industry conferences and training sessions enhances practical knowledge, keeping professionals informed of the latest innovations and best practices in slurry pump technology. In conclusion, the vapor blasting slurry pump is a specialized piece of equipment that demands a nuanced understanding of its specifications, materials, and energy requirements. Selecting and maintaining the right pump involves a blend of expert knowledge, real-world experience, and authoritative industry insights. By prioritizing these elements, companies can achieve optimal vapor blasting results, driving efficiency and effectiveness in their operations. As industries evolve, keeping abreast of new technologies and developments in slurry pumps will be essential for maintaining a competitive edge, ensuring sustainability, and meeting ever-increasing performance standards.

Previous:

Next:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024