-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 16:47

Back to list

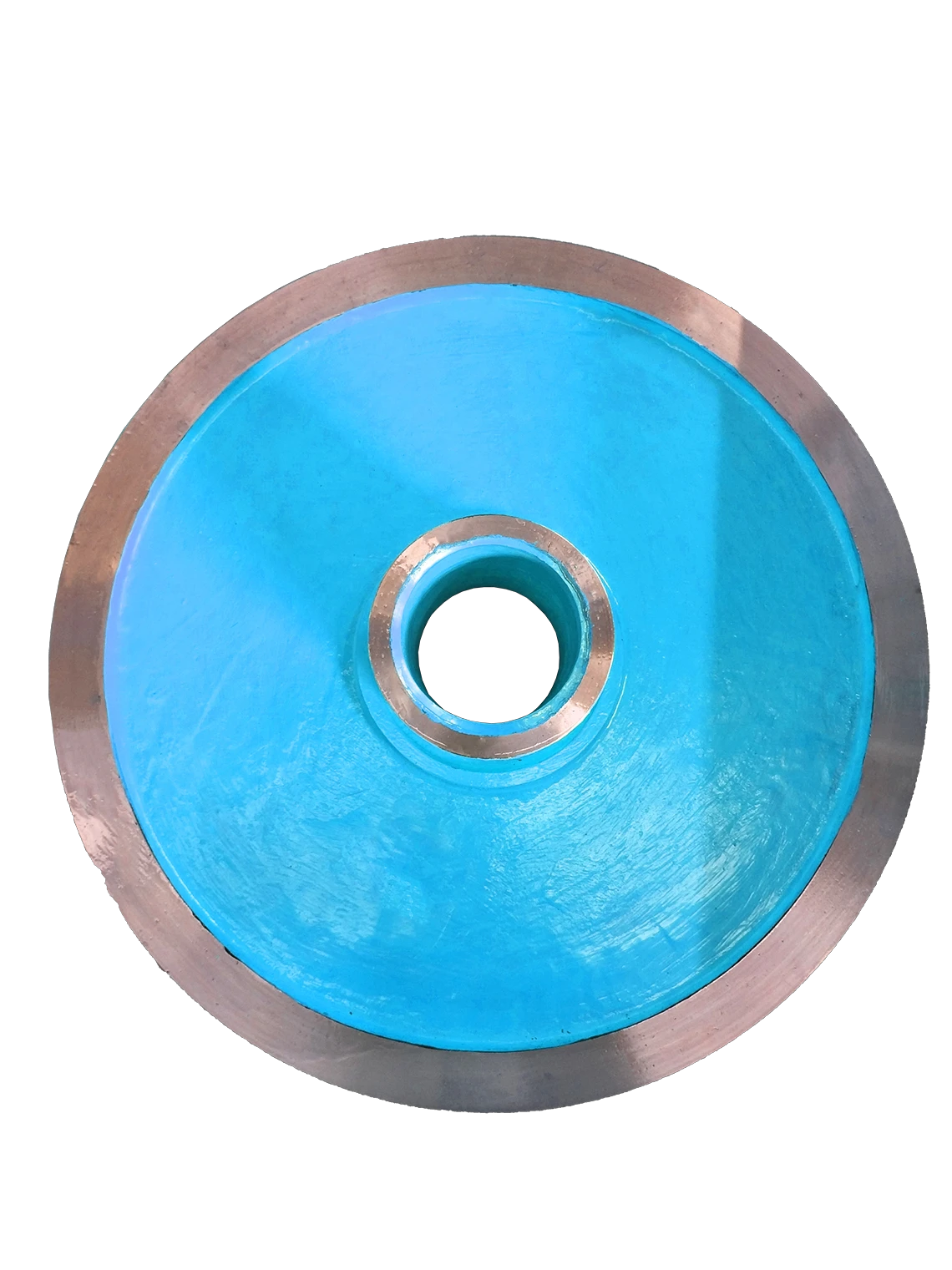

Pump Wear Parts SP20206 Metal

Volute type pumps have long been a staple in various industrial applications due to their efficient flow characteristics and robust design. Specializing in handling a diverse range of fluids—from water to more viscous substances—these pumps are pivotal in operations across industries such as water treatment, chemical processing, and wastewater management. Understanding their key features and benefits can significantly enhance the procurement process, ensuring long-term value and dependability.

Trustworthiness in the context of volute type pumps also pertains to their safety features. Comprehensive designs typically include fail-safes such as sealed chambers to prevent leaks and backflow preventers that ensure operational integrity. These technical safeguards not only protect the machinery but also guarantee operator safety and environmental compliance. In terms of real-world experience, testimonials from seasoned engineers and plant operators who have worked with volute type pumps are invaluable. Their insights often focus on the ease of maintenance and efficiency improvements observed after integrating these pumps into existing systems. Preventative maintenance strategies and the availability of replacement parts also play a crucial role in maintaining operational efficiency, reducing the total cost of ownership for businesses. To optimize user experience with volute type pumps, it’s advisable to engage with certified professionals for installation and regular inspection. Compliance with operational guidelines and periodic reviews by expert engineers ensures that performance metrics are consistently met, aligning with the anticipated operational targets. In conclusion, the decision to invest in volute type pumps should be informed by a comprehensive understanding of their mechanical advantages, field-tested reliability, and robust safety features. By focusing on these factors, businesses can leverage the inherent strengths of volute type pumps, ensuring seamless operation and contributing to overall project success. Adopting a strategic approach when selecting, installing, and maintaining these pumps can deliver significant returns in efficiency and reliability, making them a cornerstone of any sound industrial strategy.

Trustworthiness in the context of volute type pumps also pertains to their safety features. Comprehensive designs typically include fail-safes such as sealed chambers to prevent leaks and backflow preventers that ensure operational integrity. These technical safeguards not only protect the machinery but also guarantee operator safety and environmental compliance. In terms of real-world experience, testimonials from seasoned engineers and plant operators who have worked with volute type pumps are invaluable. Their insights often focus on the ease of maintenance and efficiency improvements observed after integrating these pumps into existing systems. Preventative maintenance strategies and the availability of replacement parts also play a crucial role in maintaining operational efficiency, reducing the total cost of ownership for businesses. To optimize user experience with volute type pumps, it’s advisable to engage with certified professionals for installation and regular inspection. Compliance with operational guidelines and periodic reviews by expert engineers ensures that performance metrics are consistently met, aligning with the anticipated operational targets. In conclusion, the decision to invest in volute type pumps should be informed by a comprehensive understanding of their mechanical advantages, field-tested reliability, and robust safety features. By focusing on these factors, businesses can leverage the inherent strengths of volute type pumps, ensuring seamless operation and contributing to overall project success. Adopting a strategic approach when selecting, installing, and maintaining these pumps can deliver significant returns in efficiency and reliability, making them a cornerstone of any sound industrial strategy.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024