-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 15, 2025 16:30

Back to list

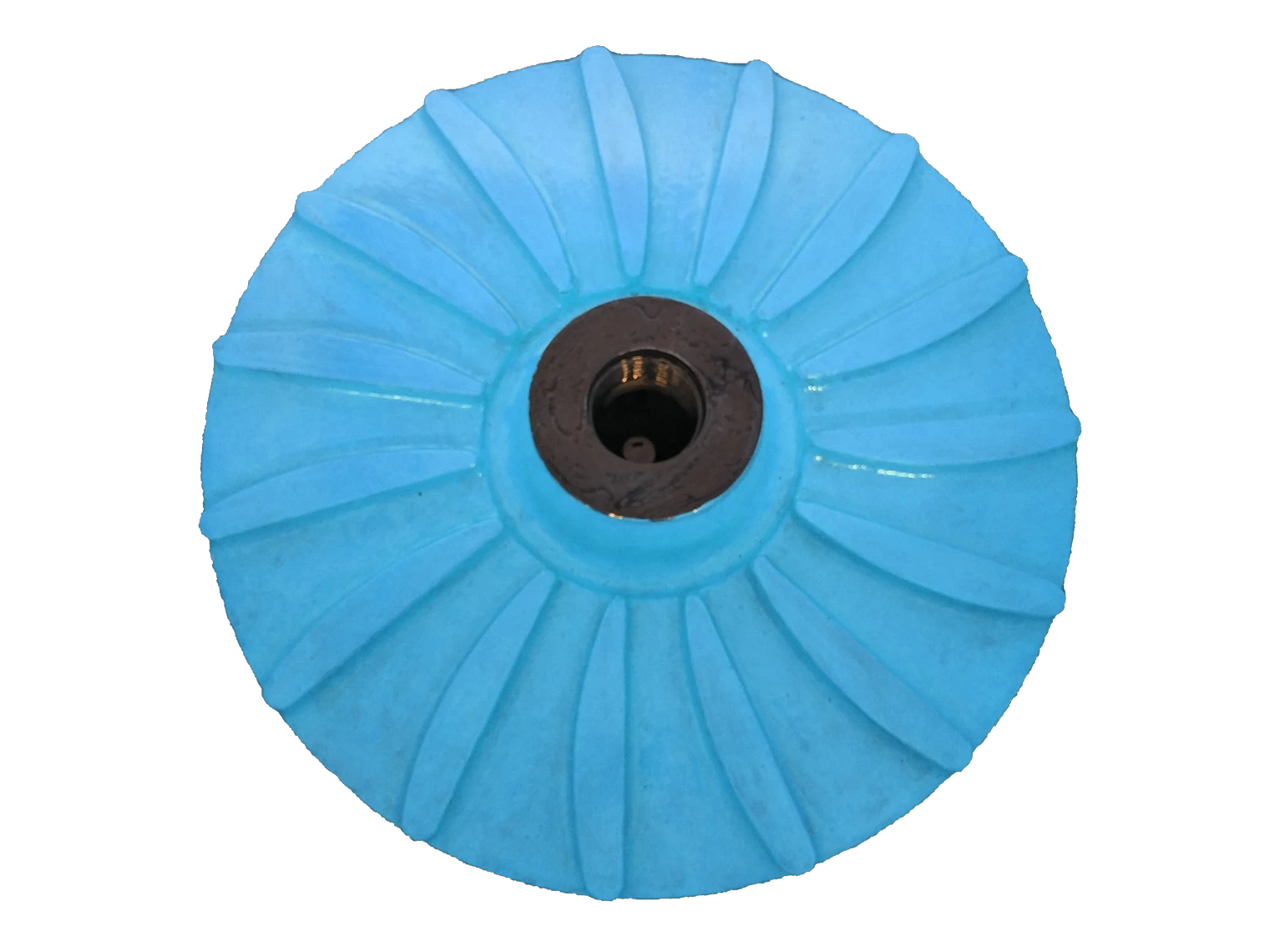

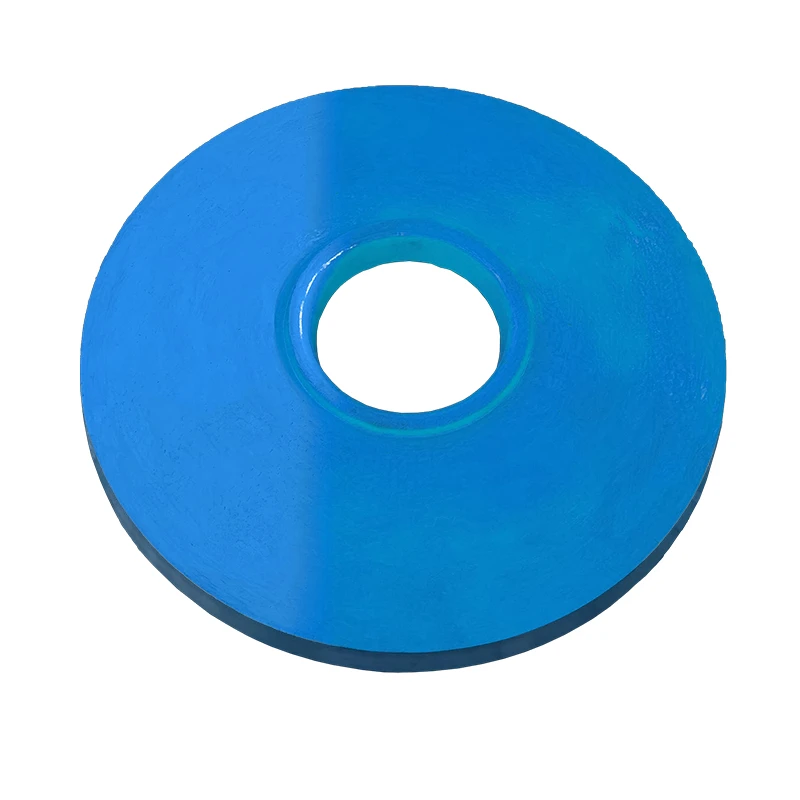

Pump Wear Parts C2017, Rubber Front Sheath

In the realm of fluid handling and machinery, the volute pump housing stands as a cornerstone in ensuring efficiency and longevity. This vital component is particularly revered in industries where precision and reliability are non-negotiable – such as oil and gas, water treatment, and chemical processing. The role it plays cannot be overstated, making it essential to delve into its features, benefits, and best practices for selection and maintenance with an expertise perspective.

Maintenance is another cornerstone that upholds the trustworthiness of volute pump housing. Regular inspections for signs of wear, such as erosion or corrosion, are imperative to preclude operational failures. Adopting a proactive maintenance strategy, incorporating predictive tools, can significantly extend the lifespan of the housing. Techniques such as ultrasonic testing and thermographic imaging provide non-invasive methods to monitor the health of the housing and identify potential issues before they escalate. The authority of a volute pump housing also lies in its design innovation. Manufacturers continue to push the envelope with designs that enhance efficiency and durability. Cutting-edge developments, such as the use of composite materials that blend high strength and low weight, are setting new benchmarks in the industry. Moreover, advancements in additive manufacturing – such as 3D printing – offer the potential for customized and complex geometries that were previously unattainable, promising even greater efficiency enhancements. Conversely, the installation of the volute pump housing is an art that demands expertise and precision. Ensuring proper alignment and secure mounting reduce the risk of vibration and its associated wear. Furthermore, employing condition monitoring systems can provide real-time data on operational parameters, ensuring that the housing performs within its optimal range. Understanding the significance of environmental impact, modern volute designs are developed with sustainability in mind. The drive toward energy efficiency has seen the integration of eco-design principles in pump housing manufacture, aiming to reduce the carbon footprint while maintaining performance standards. In conclusion, the volute pump housing is far more than just a structural component; it is a central figure in the efficient transfer and control of fluids. As industries evolve, so does the technology behind these critical components. By harnessing cutting-edge manufacturing techniques, material advancements, and design innovations, volute pump housings continue to set new standards for efficiency and reliability. For businesses reliant on optimal fluid dynamics, engaging with trusted manufacturers and adhering to rigorous maintenance protocols ensure that their systems perform at their peak, safeguarding both process integrity and profitability.

Maintenance is another cornerstone that upholds the trustworthiness of volute pump housing. Regular inspections for signs of wear, such as erosion or corrosion, are imperative to preclude operational failures. Adopting a proactive maintenance strategy, incorporating predictive tools, can significantly extend the lifespan of the housing. Techniques such as ultrasonic testing and thermographic imaging provide non-invasive methods to monitor the health of the housing and identify potential issues before they escalate. The authority of a volute pump housing also lies in its design innovation. Manufacturers continue to push the envelope with designs that enhance efficiency and durability. Cutting-edge developments, such as the use of composite materials that blend high strength and low weight, are setting new benchmarks in the industry. Moreover, advancements in additive manufacturing – such as 3D printing – offer the potential for customized and complex geometries that were previously unattainable, promising even greater efficiency enhancements. Conversely, the installation of the volute pump housing is an art that demands expertise and precision. Ensuring proper alignment and secure mounting reduce the risk of vibration and its associated wear. Furthermore, employing condition monitoring systems can provide real-time data on operational parameters, ensuring that the housing performs within its optimal range. Understanding the significance of environmental impact, modern volute designs are developed with sustainability in mind. The drive toward energy efficiency has seen the integration of eco-design principles in pump housing manufacture, aiming to reduce the carbon footprint while maintaining performance standards. In conclusion, the volute pump housing is far more than just a structural component; it is a central figure in the efficient transfer and control of fluids. As industries evolve, so does the technology behind these critical components. By harnessing cutting-edge manufacturing techniques, material advancements, and design innovations, volute pump housings continue to set new standards for efficiency and reliability. For businesses reliant on optimal fluid dynamics, engaging with trusted manufacturers and adhering to rigorous maintenance protocols ensure that their systems perform at their peak, safeguarding both process integrity and profitability.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024