-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 04, 2025 02:51

Back to list

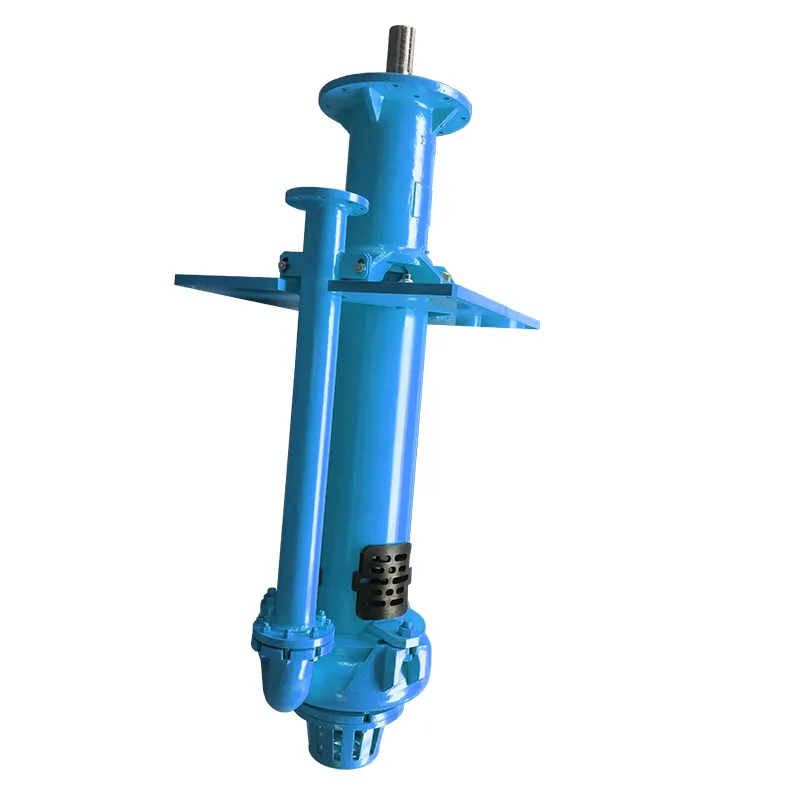

vertical vs horizontal centrifugal pump

Centrifugal pumps serve as crucial components in various industries, each offering an array of designs tailored to specific applications. Among them, vertical and horizontal centrifugal pumps dominate. Choosing between these two involves understanding their structures, functionalities, and benefits in specific applications.

Authoritativeness in any pump discussion is deeply rooted in understanding the historical evolution and technological advancements that these pumps have undergone. Vertical pumps, engineered initially for oil industry applications, have advanced over decades to support varied needs like deep borehole water extraction. Meanwhile, horizontal pumps, leveraging advancements in seal technologies and materials, have expanded their utility across assorted industries including petrochemical and HVAC systems. Trustworthiness is established through third-party validations and real-world performance reviews. Field studies indicate that vertical centrifugal pumps often offer superior energy efficiency, particularly in installations where shaft alignment issues might arise with horizontal pumps. However, horizontal pumps tend to involve lower upfront costs, attributable to their more straightforward configuration, which is reflected favorably in customer ROI assessments. In product decision-making scenarios, the choice between vertical and horizontal centrifugal pumps must be primarily guided by application requirements and long-term operational goals. Considerations should extend beyond initial purchase costs to encompass factors like energy efficiency, maintenance simplicity, and lifecycle operating costs. Enterprises lean towards consultants and engineers who can provide tailored insights and recommendations honed by industry-specific experience and expertise. In conclusion, while both vertical and horizontal centrifugal pumps have proven their mettle across various industrial applications, their selection must prioritize spatial, operational, and efficiency parameters intrinsic to the intended use. As industry professionals continue to dissect pump performance and durability, understanding these pumps' nuanced differences enhances decision-making efficacy, ultimately impacting strategic operational excellence in process industries globally.

Authoritativeness in any pump discussion is deeply rooted in understanding the historical evolution and technological advancements that these pumps have undergone. Vertical pumps, engineered initially for oil industry applications, have advanced over decades to support varied needs like deep borehole water extraction. Meanwhile, horizontal pumps, leveraging advancements in seal technologies and materials, have expanded their utility across assorted industries including petrochemical and HVAC systems. Trustworthiness is established through third-party validations and real-world performance reviews. Field studies indicate that vertical centrifugal pumps often offer superior energy efficiency, particularly in installations where shaft alignment issues might arise with horizontal pumps. However, horizontal pumps tend to involve lower upfront costs, attributable to their more straightforward configuration, which is reflected favorably in customer ROI assessments. In product decision-making scenarios, the choice between vertical and horizontal centrifugal pumps must be primarily guided by application requirements and long-term operational goals. Considerations should extend beyond initial purchase costs to encompass factors like energy efficiency, maintenance simplicity, and lifecycle operating costs. Enterprises lean towards consultants and engineers who can provide tailored insights and recommendations honed by industry-specific experience and expertise. In conclusion, while both vertical and horizontal centrifugal pumps have proven their mettle across various industrial applications, their selection must prioritize spatial, operational, and efficiency parameters intrinsic to the intended use. As industry professionals continue to dissect pump performance and durability, understanding these pumps' nuanced differences enhances decision-making efficacy, ultimately impacting strategic operational excellence in process industries globally.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024