-

support@minemaxx.com

support@minemaxx.com

-

0086-311-87833311

0086-311-87833311

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

NO.8 JIHENG STREET,QIAOXI DISTRICT,SHIJIAZHUANG,HEBEI,CHINA

2 月 . 04, 2025 03:13

Back to list

vertical centrifugal pump design

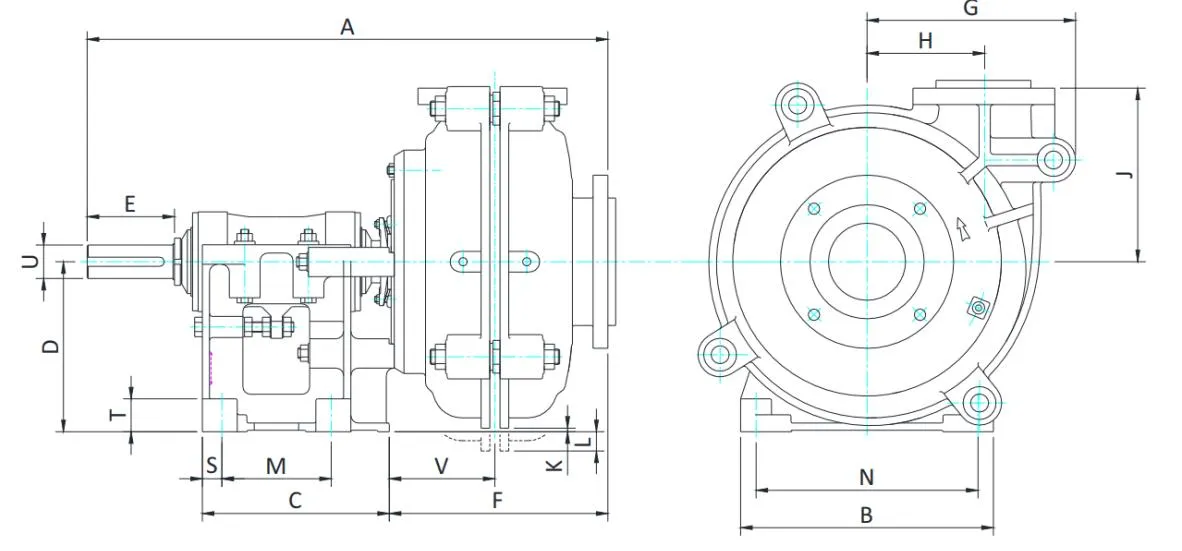

Vertical centrifugal pump design stands as a cornerstone in various industrial applications. Craftsmen in the field understand that these pumps offer significant advantages over their horizontal counterparts, particularly in limited space installations, where every inch of room counts. The unique design aligns itself with the gravitational flow, minimizing the burden on the supporting structures and offering improved efficiency even under high-pressure tasks. This feature is particularly beneficial in industrial environments where space is restricted and resource optimization is critical.

Adopting an authoritative approach, it's worth noting that regulatory compliance and adhering to international standards is non-negotiable. Certified pumps that meet international standards such as ISO or ANSI are a testament to their credibility and efficiency. These certifications also ensure that the pumps are safe to use, reliable, and reflect high manufacturing quality—an assurance that meets and often exceeds the rigorous demands of industrial users. Trust is built when the supplier is able to provide documented proof of compliance, reducing any potential risks associated with pump failure. Integrating the latest technology in vertical centrifugal pump design is where innovation meets expertise. Smart sensors and automation systems can now be integrated into these pumps, allowing real-time monitoring and data analytics. This technological advancement ensures operational efficiency, as data can be used to predict maintenance needs and optimize pump performance without human intervention. Such innovations are indispensable in modern-day industries striving for lean operations and cost reduction through smart management. In wrapping up, vertical centrifugal pumps represent a confluence of experience, expertise, and authority in design and application. When these factors align, they create a trustworthy product that not only fulfills operational requirements but does so with unmatched reliability. For businesses prioritizing sustainability and efficiency, embracing the design nuances of vertical centrifugal pumps can offer a competitive edge and contribute significantly to their operational success.

Adopting an authoritative approach, it's worth noting that regulatory compliance and adhering to international standards is non-negotiable. Certified pumps that meet international standards such as ISO or ANSI are a testament to their credibility and efficiency. These certifications also ensure that the pumps are safe to use, reliable, and reflect high manufacturing quality—an assurance that meets and often exceeds the rigorous demands of industrial users. Trust is built when the supplier is able to provide documented proof of compliance, reducing any potential risks associated with pump failure. Integrating the latest technology in vertical centrifugal pump design is where innovation meets expertise. Smart sensors and automation systems can now be integrated into these pumps, allowing real-time monitoring and data analytics. This technological advancement ensures operational efficiency, as data can be used to predict maintenance needs and optimize pump performance without human intervention. Such innovations are indispensable in modern-day industries striving for lean operations and cost reduction through smart management. In wrapping up, vertical centrifugal pumps represent a confluence of experience, expertise, and authority in design and application. When these factors align, they create a trustworthy product that not only fulfills operational requirements but does so with unmatched reliability. For businesses prioritizing sustainability and efficiency, embracing the design nuances of vertical centrifugal pumps can offer a competitive edge and contribute significantly to their operational success.

Previous:

Latest news

-

Wet Parts for Optimal PerformanceNewsOct.10,2024

-

Vertical Pump Centrifugal SolutionsNewsOct.10,2024

-

Top Slurry Pump ManufacturersNewsOct.10,2024

-

The Ultimate Guide to Centrifugal Pump for SlurryNewsOct.10,2024

-

Pump Bearing Types for Optimal PerformanceNewsOct.10,2024

-

A Guide to Top Slurry Pump SuppliersNewsOct.10,2024

-

Slurry Pump Parts for Optimal PerformanceNewsSep.25,2024